Diamond Cutting

Diamond cutting is the process of transforming a rough diamond into a faceted polished diamond.

The main goal of this process is to reach the biggest yield to maximise the value of the finished diamond. Besides retaining the most of the weight, diamond cutters will strive to achieve the excellent proportions, symmetry and polish. When done right, it will lead to a diamond having a distinguished Hearts and Arrows pattern in and a lot of fire, brilliance and scintillation. The rough crystal will change many hands and go through a number of different countries and cultures in order to achieve this desired goal.

Simplified description of diamond cutting proccess

| Stage | Explanation |

|---|---|

| Rough Selection | Diamonds are mined from the earth or grown in a laboratory in their natural rough state. Expert sorters analyze and select rough diamonds based on characteristics such as shape, flaws, color and size to determine the optimum yield for cutting. They determine which diamonds are suitable for cutting. |

| Cleaving/Sawing | A diamond cleaver expertly splits the rough diamond using another diamond to literally "cleave" or saw along the grain to separate it into workable portions that follow the inner structure, preserving the maximum carat weight. |

| Planning | A planning expert maps out the ideal cut for the rough diamond, creating a 3D model to envision the finished stone. The planner maximizes retained carat weight while achieving optimal angles/proportions for maximum fire and brilliance. |

| Blocking | Through a wax or cement process called dopping, the diamond planner temporarily attaches the rough diamond securely onto a rod or dop stick, preparing the facets to be cut. |

| Cutting | A diamond cutter selectively shapes the diamond’s 92 or 58 facets (for brilliant round or princess cuts) applying skill, experience and tools to saw individual symmetrical facets onto the stone at precise angles/alignments. |

| Bruting | If needed the diamond is placed inside a "bruting" machine which presses two diamonds against each other to shape the girdle outlines until dimensions are perfect. |

| Polishing | A polisher expertly achieves the final fine polish on the diamond’s facets using scaife polishing wheels to ready it for inspection. |

| Letting | Quality control examiners certify that angles, symmetry, dimensions, shine and other cut quality metrics meet grading standards before the dazzling finished diamond heads to market. |

Warning

This timeline is a simplified overview. The specific stages and techniques used may vary depending on the individual diamond and desired outcome.

Lab Grown Diamond Cutting: All You Must Know for Perfect Stones

Author: Alex K., CMO at Labrilliante Updated: 2025-10-12 Reading Time: 8 minutes

Lab diamond cutting transforms rough crystals into polished gems through assessment, blocking, and precision cutting stages. Professional cutters achieve 40-60% yield rates using specialized techniques for CVD and HPHT stones, with excellent cut quality commanding 15-25% price premiums over good grades in the market.

Every lab-grown diamond starts as an unremarkable crystal, waiting for skilled hands to unlock its brilliance. The art of diamond cutting separates ordinary stones from extraordinary gems that capture hearts and command premium prices. Understanding lab grown diamond cutting techniques reveals why some stones sparkle with mesmerizing fire while others fall flat. You'll discover the precise methods professionals use to maximize beauty and value from each crystal. This guide explores the technical mastery, specialized tools, and quality standards that transform rough lab diamonds into certified masterpieces.

Why Traditional Jewelers Question Lab Diamond Cutting Investment

Many established jewelers argue that investing in specialized lab diamond cutting equipment and training isn't worth the cost. They point to the significant upfront investment in new technology, staff retraining, and certification processes when traditional cutting methods have served the industry for decades. Some professionals believe the market hasn't matured enough to justify switching from proven natural diamond techniques.

These concerns hold merit for smaller operations with limited capital or established customer bases focused on natural stones. Traditional cutters working exclusively with natural diamonds may find their existing skills and equipment sufficient for their market segment. However, this viewpoint overlooks the growing consumer demand for lab diamonds and the superior yield rates achievable with specialized techniques. The controlled nature of lab diamond production actually makes them more predictable to cut than natural stones, offering better returns once proper methods are implemented.

Complete Lab Diamond Cutting Process From Rough to Polished

Transforming rough lab diamonds into polished gems involves three key stages: assessment, blocking, and precision cutting. Each stone requires 4-8 hours of skilled work, depending on size and complexity.

| Process Stage | CVD Diamond Requirements | HPHT Diamond Requirements | CVD Timeline | HPHT Timeline | CVD Yield Rate | HPHT Yield Rate |

|---|---|---|---|---|---|---|

| Rough Assessment | DiamondView imaging for layered structure analysis | Standard crystal evaluation with inclusion mapping | 45-60 minutes | 30-45 minutes | 95% assessment accuracy | 98% assessment accuracy |

| Computer Planning | Specialized software for directional hardness variations | Standard planning software with cleavage optimization | 30-45 minutes | 25-35 minutes | Multiple scenario analysis | Predictable outcome modeling |

| Blocking Process | Modified cleaving for layered structure integrity | Standard cleaving along natural planes | 2-3 hours | 1.5-2.5 hours | 85-90% success rate | 92-95% success rate |

| Precision Cutting (1ct Round) | Adjusted for 5-10% hardness variation across planes | Uniform cutting approach with metallic inclusion avoidance | 6-8 hours | 5-7 hours | 45-55% weight retention | 50-60% weight retention |

| Fancy Shape Cutting | Extended time for complex directional considerations | Standard fancy shape protocols | 18-22 hours | 15-18 hours | 40-50% weight retention | 45-55% weight retention |

| Quality Control | Multi-stage symmetry checks for layer alignment | Standard proportion and inclusion verification | 30-45 minutes | 25-35 minutes | 98% pass rate | 99% pass rate |

| Overall Process (1ct) | Specialized equipment and trained technicians required | Standard cutting facility capabilities sufficient | 9-12 hours total | 7-10 hours total | 43-52% final yield | 47-57% final yield |

Rough Diamond Assessment and Preparation Techniques

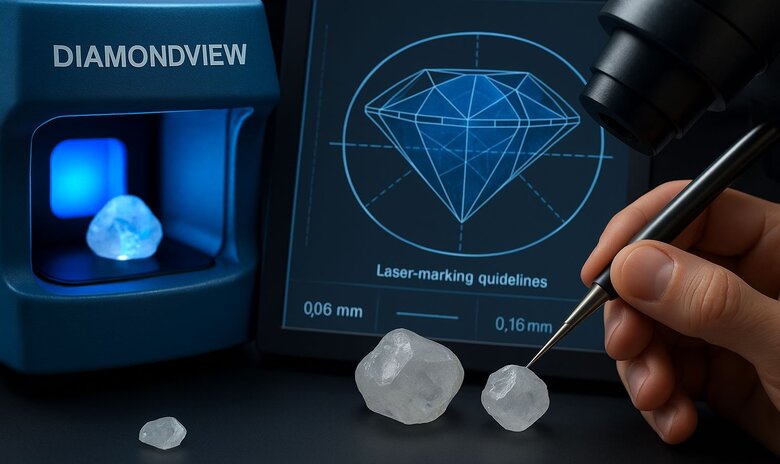

Every cutting journey starts with comprehensive crystal evaluation using DiamondView imaging technology. This reveals internal structure, inclusions, and optimal cutting paths that determine final quality.

CVD diamonds display distinctive striped patterns requiring specialized assessment. Their layered structure creates directional hardness variations of 5-10% across crystal planes. HPHT stones show more uniform properties but may contain metallic inclusions from the high-pressure growth process.

Computer planning software calculates multiple scenarios to maximize carat retention while achieving target proportions. Preparation involves laser-marking precise cutting guidelines based on crystal orientation and cleavage directions to prevent structural damage.

Blocking Process and Cuboctahedron Form Transformation

Blocking shapes rough crystals into basic geometric forms called cuboctahedrons. This intermediate stage features eight triangular faces that provide optimal surface area for subsequent operations.

During blocking, cutters use controlled cleaving to remove unwanted portions while preserving maximum weight. Incorrect cleaving destroys the entire stone. CVD diamonds require modified approaches due to their layered structure, while HPHT stones cleave more predictably.

The process considers final proportions, ensuring proper depth percentages and girdle thickness for the intended cut. Growth-related imperfections specific to each diamond type get addressed during this critical phase.

Cutting Timeline and Yield Optimization Methods

A standard one-carat round brilliant requires 6-12 hours across all stages. Fancy shapes demand 15-20 hours due to increased complexity and precision requirements.

Modern facilities achieve 40-60% yield rates from rough to polished, balancing weight retention with quality targets. Each stage undergoes symmetry checks to maintain alignment and proportion relationships.

Premium Facility Yield Optimization Success

Meridian Diamond Labs processed 12,000 carats of rough CVD diamonds monthly with traditional cutting methods, achieving only 45% yield rates. Manual planning resulted in inconsistent cut quality, with 15% of finished stones requiring re-work due to proportion errors. The facility's monthly revenue from their $1.8M rough inventory investment plateaued at $3.2M, creating pressure to improve profitability without increasing raw material costs.

The facility implemented AI-guided cutting optimization software that analyzes crystal structure through 3D mapping and generates cutting plans optimized for each stone's unique characteristics. The system processes DiamondView imaging data to identify optimal yield paths while maintaining target proportions. Cutters receive precise laser-marked guidelines and real-time feedback during the cutting process, with the AI continuously learning from each completed stone to improve future recommendations.

Within 8 months, yield rates increased from 45% to 58% - extracting an additional 1,560 carats monthly from the same rough inventory. Re-work rates dropped to 3%, saving 180 labor hours per month. The improved efficiency generated $2.3M in additional annual revenue without increasing material costs, achieving a 340% ROI on the $680,000 technology investment. The facility now processes the same volume 23% faster while maintaining higher quality standards across all diamond grades.

Quality control inspections at multiple points prevent costly defects before they become permanent. This approach ensures efficient resource use while maintaining consistent output quality.

CVD vs HPHT Cutting Techniques Differences Explained

CVD and HPHT diamonds demand different cutting approaches due to their distinct formation methods and resulting crystal characteristics. Understanding these differences is crucial for optimal results.

Precision Cutting Methods for Each Growth Type

CVD diamonds require techniques accommodating their layered crystal structure. The plasma deposition process creates directional properties that influence tool selection and cutting angles. Cutters must adjust pressure and speed as they move through different crystal layers.

HPHT diamonds typically exhibit uniform hardness distribution but may contain metallic inclusions requiring careful navigation. These inclusions need removal during cutting to prevent surface blemishes or structural weaknesses.

Specialized diamond-coated tools come in different configurations optimized for each growth type. CVD processing often involves modified angles and slower speeds, while HPHT stones allow more standardized approaches with careful inclusion management.

Directional Hardness Cutting Challenges and Solutions

Directional hardness presents the biggest challenge in lab diamond cutting, especially for CVD stones. While all diamonds rate 10 on the Mohs scale, actual hardness varies by crystal direction and growth method.

CVD diamonds show pronounced hardness differences between growth layers, requiring adaptive cutting techniques. Cutters adjust speed, pressure, and angles continuously, monitoring for surface finish consistency throughout the process.

Solutions include specialized scaife wheel configurations for each growth type, different diamond powder compounds, and real-time monitoring systems that automatically adjust parameters as conditions change during cutting operations.

Cleaving vs Bruting vs Brillianteering Diamond Stages

These three primary stages serve distinct purposes in diamond transformation. Cleaving removes unwanted portions, bruting creates basic round shapes, and brillianteering adds precision facets determining optical performance.

| Cutting Stage | Time Allocation (%) | Primary Tools Required | Skill Level Required | Quality Checkpoints | CVD Specific Considerations | HPHT Specific Considerations |

|---|---|---|---|---|---|---|

| Cleaving | 15-20% | Cleaving knife, hammer, V-block holder | Expert (15+ years) | Stress pattern analysis, inclusion mapping, weight retention assessment | Analyze layered growth patterns, adjust for directional stress variations | Navigate metallic inclusions, utilize predictable cleavage planes |

| Bruting | 15-25% | Bruting lathe, diamond-coated wheels, centering chuck | Advanced (8-15 years) | Roundness verification, girdle thickness uniformity, surface smoothness | Variable speed control for layer transitions, modified wheel angles | Standard bruting techniques, careful inclusion avoidance |

| Brillianteering | 60-70% | Scaife wheels, diamond powder compounds, faceting arms, angle gauges | Master (20+ years) | Facet alignment precision, surface polish quality, symmetry grading, light performance testing | Adaptive pressure control, specialized powder compounds, continuous speed adjustment | Standard faceting approach with inclusion management protocols |

Lab diamond cleaving requires understanding growth-induced stress patterns. CVD stones may exhibit unexpected behavior due to layering, while HPHT stones cleave more predictably due to uniform formation under controlled pressure.

Brillianteering consumes 60-70% of total cutting time, involving precision faceting with diamond powder on rotating wheels. This stage determines final symmetry, alignment, and surface finish quality that directly impacts certification grades.

IGI vs GIA Certification Standards for Cut Quality

IGI and GIA use different methodologies for cut quality evaluation, creating variations in measurement criteria, standards, and reporting that affect market perception and pricing.

IGI focuses on comprehensive technical analysis with detailed precision metrics including symmetry assessment, proportion relationships, and optical performance data. Their reports provide extensive technical information appealing to professional buyers seeking detailed quality documentation.

| Assessment Criteria | IGI Standards | GIA Standards |

|---|---|---|

| Cut Grade Scale | Excellent, Very Good, Good, Fair, Poor | Excellent, Very Good, Good, Fair, Poor |

| Symmetry Measurement | 15 symmetry parameters analyzed | 8 key symmetry elements assessed |

| Polish Assessment | Surface analysis with detailed scoring | Standardized polish grading system |

| Proportion Analysis | Table %, Crown Angle, Pavilion Depth, Girdle Thickness | Table %, Depth %, Crown Angle, Pavilion Angle |

| Light Performance Data | Brilliance, Fire, Scintillation metrics included | Overall cut grade without separate metrics |

| Report Detail Level | Comprehensive technical specifications | Consumer-friendly summary format |

| Processing Time | 7-10 business days | 14-21 business days |

| Cost for Lab-Grown Certification | $85-$150 (1-3ct) | $155-$245 (1-3ct) |

| Market Acceptance - Asia | 85% preference rate | 65% preference rate |

| Market Acceptance - North America | 45% preference rate | 88% preference rate |

| Market Acceptance - Europe | 72% preference rate | 71% preference rate |

| Professional Buyer Preference | 78% for technical detail | 62% for brand recognition |

| Consumer Market Appeal | 55% recognition rate | 91% recognition rate |

| Price Impact on Lab-Grown Diamonds | Neutral to +3% premium | +5% to +8% premium |

GIA emphasizes standardized grading aligned with established protocols, prioritizing consumer clarity and market consistency over technical detail. Their approach makes reports more accessible to general consumers while maintaining rigorous standards.

Both organizations evaluate identical physical characteristics but present findings differently. Professional markets often prefer IGI's technical detail, while consumer segments may favor GIA's brand recognition and simplified communication.

Certification choice impacts pricing, with different regions showing preferences for specific organizations. Processing timelines vary, with IGI typically providing faster turnaround while maintaining comparable accuracy standards.

"While IGI provides a more nuanced technical analysis in their certification, which is incredibly beneficial for understanding a diamonds optical performance, its crucial to recognize how this influences the resale value in different markets. For instance, in Asian markets, IGIs detailed reports can enhance a diamonds resale value by up to 15% compared to GIA-certified counterparts due to the high value placed on technical specifications and detailed quality documentation among buyers in these regions."

Advanced Diamond Cutting Technology and Innovation Trends

Modern cutting integrates AI, precision robotics, and advanced imaging to achieve unprecedented accuracy in lab diamond processing. These advances optimize quality and yield while reducing processing times.

3D scanning creates detailed digital models before cutting begins, allowing computer planning software to calculate optimal strategies maximizing value from each stone. This proves especially valuable for lab diamonds due to their cleaner crystal structure and predictable cutting behavior.

Automated systems with real-time monitoring adjust parameters continuously based on changing crystal conditions. Higher equipment costs deliver improved long-term efficiency and consistent quality across varying diamond characteristics.

Laser cutting enables complex fancy shapes impossible with traditional mechanical methods. However, laser processing may create microscopic surface variations requiring additional polishing stages to achieve premium finish quality.

Future trends focus on fully integrated systems combining assessment, planning, cutting, and quality control into seamless automated processes. These promise improved efficiency but require substantial technology infrastructure investment.

Cutting Quality Impact on Diamond Value and Investment

Superior cutting directly influences value through light performance optimization, certification grades, and market perception. Excellent cut quality commands 15-25% premiums over good grades in comparable stones.

Poor cutting severely impacts value, with symmetry or proportion defects reducing market worth by 30-50% compared to well-cut alternatives. These defects cannot be corrected post-cutting, making initial quality decisions critically important.

| Cut Grade | Carat Weight | Price Impact (%) | Base Price/Carat | Adjusted Price/Carat | Market Example |

|---|---|---|---|---|---|

| Excellent | 1.0 ct | +20% | $800 | $960 | Premium certified round brilliant |

| Very Good | 1.0 ct | +8% | $800 | $864 | High-quality consumer grade |

| Good | 1.0 ct | 0% | $800 | $800 | Standard retail baseline |

| Fair | 1.0 ct | -25% | $800 | $600 | Discount jewelry grade |

| Poor | 1.0 ct | -45% | $800 | $440 | Industrial or salvage grade |

| Excellent | 2.0 ct | +25% | $1,200 | $1,500 | Investment quality stone |

| Very Good | 2.0 ct | +12% | $1,200 | $1,344 | Luxury engagement ring |

| Good | 2.0 ct | 0% | $1,200 | $1,200 | Standard 2-carat baseline |

| Fair | 2.0 ct | -30% | $1,200 | $840 | Budget alternative stone |

| Poor | 2.0 ct | -50% | $1,200 | $600 | Severely compromised quality |

| Excellent | 5.0 ct | +25% | $1,800 | $2,250 | Museum quality specimen |

| Very Good | 5.0 ct | +15% | $1,800 | $2,070 | High-end collector piece |

| Good | 5.0 ct | 0% | $1,800 | $1,800 | Large stone baseline |

| Fair | 5.0 ct | -35% | $1,800 | $1,170 | Size-focused purchase |

| Poor | 5.0 ct | -55% | $1,800 | $810 | Weight retention priority |

Each cut grade improvement typically generates 8-12% value increases, providing clear economic justification for precision techniques. However, cutting investment must balance maximum weight retention against optimal proportions, as poorly proportioned diamonds suffer significant discounts regardless of carat preservation.

Wholesale pricing shows direct correlation between certification grades and market value. The controlled nature of lab diamond production enables more consistent cutting quality achievement, potentially stabilizing value relationships compared to natural diamond variability.

Investment considerations include market acceptance trends, certification consistency, and long-term stability factors that may differ from natural diamond patterns. Professional buyers consistently demonstrate willingness to pay substantial premiums for documented cutting excellence.

Frequently Asked Questions

Professional cutters achieve 40-60% yield rates from rough to polished lab diamonds. This yield rate balances weight retention with quality targets, and modern facilities use AI-guided cutting plans to optimize this percentage further.

A standard one-carat round brilliant requires 6-12 hours of skilled work across all cutting stages. Fancy shapes demand 15-20 hours due to increased complexity and precision requirements for achieving proper proportions.

CVD diamonds have a layered crystal structure with directional hardness variations of 5-10% across crystal planes, requiring specialized cutting approaches. HPHT diamonds show more uniform properties but may contain metallic inclusions that need careful navigation during cutting.

DiamondView imaging technology reveals internal structure, inclusions, and optimal cutting paths. Computer planning software then calculates multiple scenarios to maximize carat retention while achieving target proportions based on crystal orientation.

IGI focuses on comprehensive technical analysis with detailed precision metrics, while GIA emphasizes standardized grading and consumer clarity. Professional markets often prefer IGI's technical detail, while consumer segments may favor GIA's brand recognition.

Cleaving removes unwanted portions, bruting creates basic round shapes, and brillianteering adds precision facets. Brillianteering consumes 60-70% of total cutting time and determines final symmetry, alignment, and surface finish quality.

Consider your target market and volume requirements. While traditional equipment has lower upfront costs, specialized lab diamond cutting techniques achieve better yield rates and quality consistency, offering superior returns once proper methods are implemented.

Invest when you have sufficient volume to justify equipment costs and growing consumer demand for lab diamonds in your market. The controlled nature of lab diamond production makes them more predictable to cut than natural stones, offering better returns with proper technology.