Diamond Plates

The Material for the Mechanical, Optical, and Electronics Industries

Diamond plates are emerging as a highly versatile industrial material that outperforms conventional materials in extreme environments. Advancements in chemical vapor deposition (CVD) have enabled scalable production of synthetic diamond in plates and other shapes to meet growing demand across sectors.

Diamond's unmatched hardness, heat conductivity and chemical resistance enable applications not possible with even the most advanced metals, ceramics or composites. CVD diamond plates are seeing adoption in optics, electronics, tooling, aerospace and other fields to push boundaries of speed, heat and durability.

Our CVD Diamond Material

Labrilliante is a manufacturer of CVD diamond plates in the USA. We grow polycrystalline and single-crystal diamond to exacting specifications unmatched in quality and performance.

Our diamond plates deliver premium thermal conductivity exceeding 1700 W/mK for photonics and high-power electronics. The exceptional hardness of our Tool Grades resists wear in machining of composites and reactive metals. We specialize in custom diamond solutions tailored to your most demanding applications. Our engineers collaborate with partners across aerospace, defense, energy, optics, semiconductors, tooling and beyond to understand unique requirements and actualize the enormous potential of synthesized diamond.

Labrilliante provides diamond plates across four capability grades spanning a multitude of uses where traditional materials fall short:

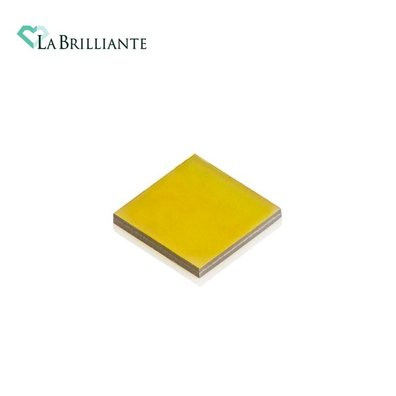

- Optical Class - tremendously heat-conducive, 1700-1800 watts per meter kelvin

- Electronic Level - exceptionally thermal conductive, 1700-1800 w/mK

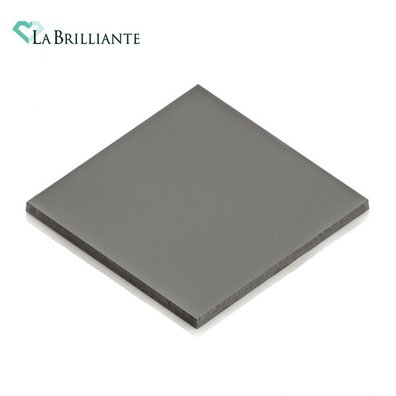

- Thermal Tier - dull diamond, 900-1000 w/mK

- Tool Category - dark diamond, 700-800 w/mK

Personalized Diamond Plate Order

You can order any plates in different sizes. We make materials to suit any application. Leave your details in the contact form below to get prices.

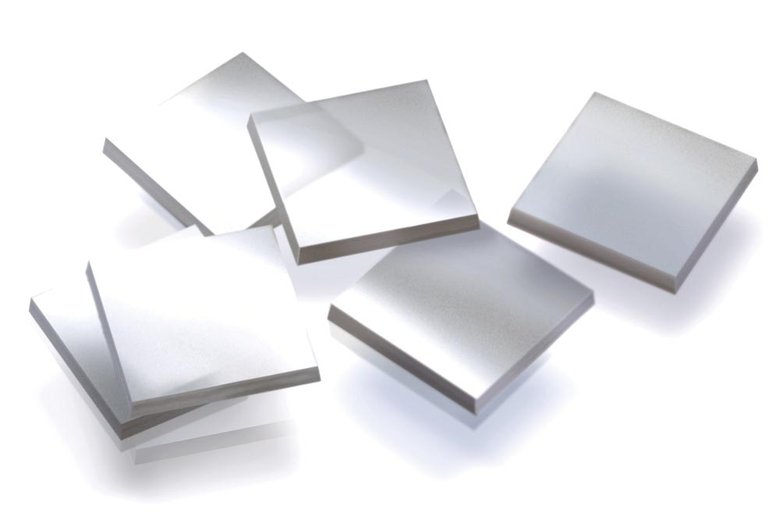

Single Crystal Diamond (SCD) Plates

SCD plates consist of one continuous diamond crystal lattice. They are created by depositing the diamond onto a small seed diamond crystal in a CVD reactor. SCD displays superior thermal conductivity (2000 W/mK) but is available in smaller sizes due to production challenges. SCD plates work well for laser optics, semiconductor fabrication and other electronics uses.

Polycrystalline CVD Diamond Plates

For larger diamond plates, tiny diamond crystallites are fused together in the CVD process to form a contiguous plate up to eight inches across. Polycrystalline diamond (PCD) exhibits slightly lower but still excellent thermal properties around 1000 W/mK. The versatile PCD format serves well for water jet nozzles, tooling, watch jewels, coatings and aerospace.

The attributes of CVD diamond plates are fueling broader adoption as manufacturing processes mature. Diamond plates deliver game-changing benefits spanning heat dissipation, wear life, corrosion resistance and precision. Please inquire to learn more about leveraging diamond plates to supercharge your demanding application.

Contact our application engineers online to explore how our CVD diamond plates can empower your designs with previously unrealizable performance extremes in temperature, corrosion and wear resistance. The possibilities are bounded only by your imagination.

FAQ Section for Diamond Plates

CVD diamond plates are used in a wide range of high-performance applications across optics, electronics, tooling, and aerospace industries. They're essential components in laser technology, high-power electronic devices, heat spreaders, advanced sensors, and medical imaging technologies where traditional materials fail. Their exceptional thermal conductivity, optical clarity, and durability make them ideal for environments with extreme heat, pressure, or chemical exposure.

Single crystal diamond plates consist of one continuous diamond crystal lattice with superior thermal conductivity (up to 2000 W/mK) but are available in smaller sizes. Polycrystalline diamond plates have multiple crystal boundaries, slightly lower thermal conductivity (1500-1800 W/mK), but can be produced in larger sizes at lower cost. Single crystals excel in optical and electronic applications, while polycrystals are preferred for thermal management and cutting tools.

CVD (Chemical Vapor Deposition) diamond plates are created by depositing carbon atoms onto a substrate in a specialized reactor. For single crystal plates, the diamond grows from a small seed crystal in carefully controlled conditions with carbon-containing gases and precise temperature settings. This process mimics natural diamond formation but occurs in a laboratory environment, allowing precise control over size, purity, and crystalline structure.

Diamond plates offer exceptional thermal conductivity ranging from 700-2000 W/mK depending on grade and structure. Optical and Electronic grade plates typically achieve 1700-1800 W/mK, while Thermal grade delivers 900-1000 W/mK, and Tool grade provides 700-800 W/mK. This makes them vastly superior to traditional heat sink materials like copper (400 W/mK) or aluminum (237 W/mK).

The maximum size of synthetic diamond plates has increased dramatically in recent years. While most plates before 2010 were smaller than half a carat, technological improvements now allow for diamond substrates up to 125 carats in 2025. Standard polycrystalline plates are available in larger dimensions than single crystal varieties, with some manufacturers offering custom sizes up to 45.0 x 45.0 mm for specialized applications

Yes, diamond plates can be extensively customized to meet specific requirements. Manufacturers like Labrilliante offer tailored solutions with varying dimensions, thicknesses, crystallographic orientations, and surface finishes. Customers can specify optical clarity, thermal conductivity targets, and surface roughness parameters (as low as Ra < 50nm) depending on their application needs

Unlike thin DLC coatings (typically 1-5 microns), diamond plates are solid pieces of synthetic diamond material ranging from 0.3mm to several millimeters thick. This gives plates substantially higher durability, thermal capacity, and performance longevity in extreme environments. While DLC coatings provide surface protection, diamond plates offer bulk material properties and can serve as structural components in devices requiring extraordinary performance.

Diamond plates exhibit exceptional longevity in industrial settings due to diamond's unmatched hardness (10 on Mohs scale). While traditional abrasives wear down quickly, diamond plates can maintain useful performance for years of daily use. The exact lifespan depends on the application, but many industrial users report 5-10 years of reliable service in demanding environments like semiconductor production, high-power electronics, and precision machining applications.