HPHT Сubic Press Machine

Labrilliante is a manufacturer of lab-grown diamonds that applies advanced HPHT cubic press technology. Our team continually refines production parameters to grow diamonds with superb clarity, color and cut. We are based in the USA and ship worldwide.

We offer fully customizable HPHT solutions with pricing scaled per specifications. All systems include intuitive controls and automation for ease of operation. You can buy Labrilliante’s cubic press machines online and tap guidance from our engineering experts.

HPHT cubic press is a machine that can produce synthetic diamond materials, including single-crystal diamonds, lab-grown diamonds, diamond powder, composite sheet, and so on. The most popular models are the 650 and 960, and others are available.

Get information on prices and availability

A High Pressure High Temperature (HPHT) cubic hydraulic press is a machine used to produce lab-grown diamonds. It works by subjecting a carbon source material, such as graphite, to extremely high pressure and temperature, simulating the conditions under which natural diamonds are formed in the Earth's crust.

As synthetic diamond markets rapidly expand worldwide, high pressure high temperature (HPHT) presses are seeing heightened demand. Companies across the globe are looking to invest in this technology.

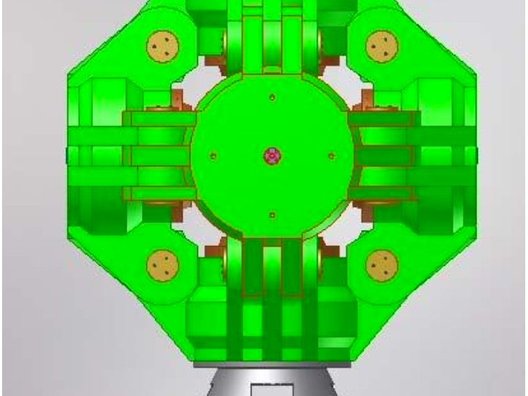

HPHT cubic presses create extreme heat and pressure to replicate the conditions under which natural diamonds form. The cubic press model features a reaction cell that enables high-volume diamond production with minimal maintenance.

Our HPHT Cubic Press Machine Models

| Press model | Anvils | Cube | Basic price* |

| 650 | φ142-φ160 | 72 | $165 000 |

| 700 | φ155-φ165 | 72 | $181 000 |

| 750 | φ165-φ175 | 74 | $197 000 |

| 800 | φ175-φ185 | 77 | $177 000 |

| 850+ glass | φ185-φ199 | 84 | $238 000 |

| 900+ glass | φ199-φ220 | 85 | $262 000 |

| 950+ glass | φ199-φ240 | 88 | $296 000 |

| 960 | φ185-φ220 | 92 | $252 000 |

| 980 | φ185-φ220 | 100 | $255 000 |

| 850(forged) | Φ199 | 74x74 84 | $253 000 |

| 900(forged) | Φ220 | 82x82 88 | $293 000 |

| 1000(forged) | Φ240 | 92x92 100 | $454 000 |

| 850(forged) | Φ199 | 74x74 84 | $258 000 |

*Basic price means that this is the factory price and includes the basic model of the press without modifications. Please note that the the additional system mechanisms, training and know-how are not included in the price. Please contact us for prices on the full configuration package.

Product Overview

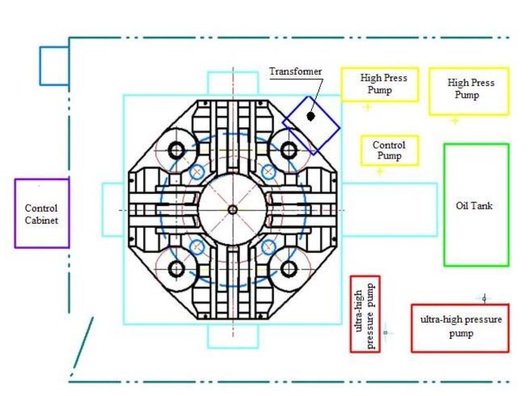

The main parts of a cubic press are usually:

- Pressure system. An array of high-power hydraulic cylinders and pistons actuated by electric pumps produce up to 1.5 million PSI of pressure - replicating the crushing forces deep inside Earth.

- Temperature control system. The press encloses the central cubic chamber in precision-controlled heating systems including resistant elements and laser emitters.

- Pressure vessel. Surrounding the core is a rigid pressure vessel architected using high-strength alloy steel. It provides an impregnable barrier for retaining the extreme temperature and pressure levels.

- Control system. Sophisticated automation technology including PLCs and PID controllers monitor and calibrate process parameters in real-time. By optimizing temperature, pressure and time configurations, they facilitate flawless manufacturing runs.HPHT Cubic Presses Powering Applications

Technical Parameters

| Model | 650 | 700 | TB-750 | 800(uncylindered) | TB-850 | 900 | 960(uncylindered) | 980(uncylindered) |

| Diameter of working cylinder (mm) | 650 | 700 | 750 | 800 | 850 | 900 | 960 | 980 |

| Design pressure (MP) | 110 | 110 | 110 | 110 | 110 | 118 | 100 | 100 |

| Cylinder force (KN) | 36000 | 42000 | 48500 | 55000 | 62000 | 75000 | 72000 | 75000 |

| Six-cylinder pressure (KN) | 6x32000 | 6x37000 | 6x42800 | 6x48700 | 6x55000 | 6x60400 | 6x57800 | 6x60000 |

| Ultra-high pressure (MP) | 97 | 97 | 97 | 97 | 97 | 95 | 80 | 80 |

| Maximum piston stroke | 90 | 90 | 90 | 90 | 100 | 100 | 100 | 100 |

| Opening height (mm) | 421 | 440 | 433 | 447 | 540 | 544 | 540 | 540 |

| Closing height (mm) | 331 | 350 | 343 | 357 | 440 | 444 | 440 | 440 |

| Electric heating power (Optional) | 40 | 40 | 40 | 40 | 40 | 60 | 60 | 60 |

| Total engine power (KW) | 22.5 (7.5+15) | 22.5 (7.5+15) | 29.5 (11+18.5) | 29.5 (11+18.5) | 29.5 (11+18.5) | 33 (11+22) | 33 (11+22) | 33 (11+22) |

| Selection punch (mm) | φ142-φ160 | φ155-φ165 | φ165-φ175 | φ175-φ185 | φ185-φ199 | φ199-φ220 | φ185-φ220 | φ185-φ220 |

| External size (L*W*H) | 2990x2990x3525 | 3170x3170x3640 | 3120x3120x3565 | 3180x3180x3740 | 3360x3360x3865 | 3330x3330x3690 | 3330x3330x3690 | 3350x3350x3710 |

| Weight (t) | 48.3 | 62.5 | 71.1 | 75.5 | 82 | 85 | 80 | 80 |

Diamond Growth Facility: Requirements and Setup

1) You can install a thick metal plate that would act as a reinforced foundation for the Press (we can assist with it, as we already have such experience).

2) You need to use the location with a thick concrete foundation and its thickness depends on the Press model, as their weights differ.

3) Electricity

4) Cooling system

5) Equipment to support the growth of large crystals

6) Equipment for preparation of materials

7) Equipment for manufacturing cell parts

Application of HPHT Cubic Press

HPHT cubic presses unleash extreme pressure and temperature to create novel materials breakthroughs across industries.

Diamond materials that are produced with the HPHT cubic press machine are widely used in industry, optics and medicine. GaN-on-Diamond semiconductors have emerged as a game-changer in the field of electronics, offering a remarkable set of properties that surpass traditional materials.

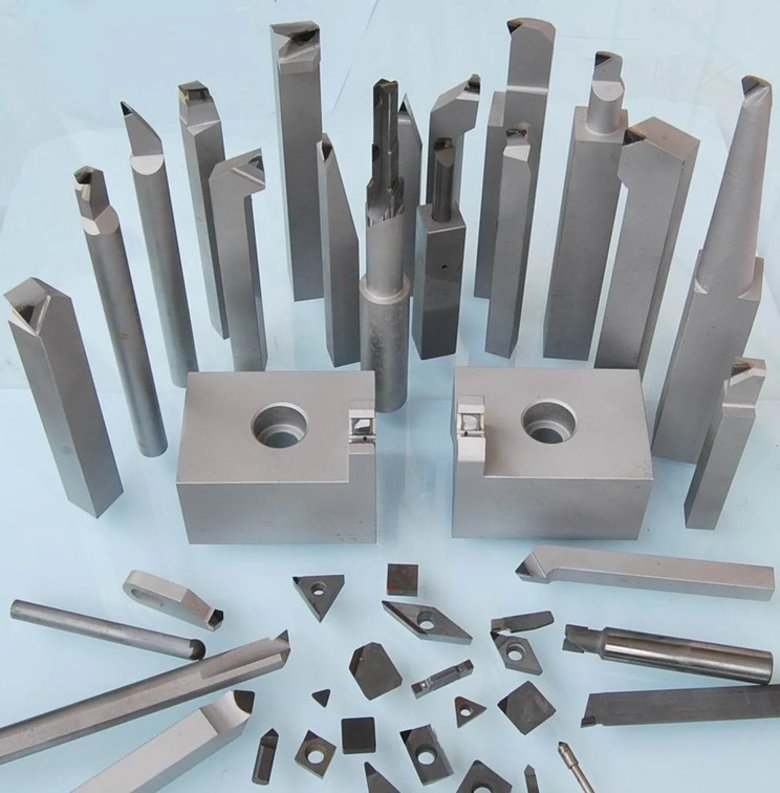

PCD

HPHT diamond machines are used to manufacture cutters and tools from polycrystalline diamond compacts (PDC). In these advanced systems, diamond precursors are subjected to extreme pressures in excess of 5 GPa and temperatures in excess of 1500°C to facilitate the synthesis of polycrystalline diamond composites. PCDs exhibit exceptional hardness and wear resistance, enabling faster and more economical oil and gas drilling operations.

Lab-Grown Diamonds

Advanced HPHT technology using laboratory diamond machines allows the growth of high quality lab grown diamonds that are as good as their mined counterparts. HPHT diamonds are more affordable and ethical than mined diamonds, alleviating concerns about the environmental impact of traditional mining methods.

PCBN and tools

The full name of PCBN is "polycrystalline cubic boron nitride," a superhard material synthesized through HPHT processes akin to those used for polycrystalline diamond fabrication. It is commonly employed in the production of cutting tools, punches, and other industrial components that demand exceptional hardness, thermal stability, and wear resistance. HPHT machines exert immense pressures and temperatures on precursor compounds, facilitating the phase transition and crystallization into the desired polycrystalline cubic boron nitride structure.

Discover Partnership Opportunities in Memorial Diamonds

If you are interested in the unique applications of lab-grown diamonds beyond industrial and technological uses, discover how HPHT technology enables the creation of meaningful keepsakes. Learn more about our partnership opportunities in the production of memorial diamonds, where advanced diamond synthesis transforms cherished memories into everlasting gems.

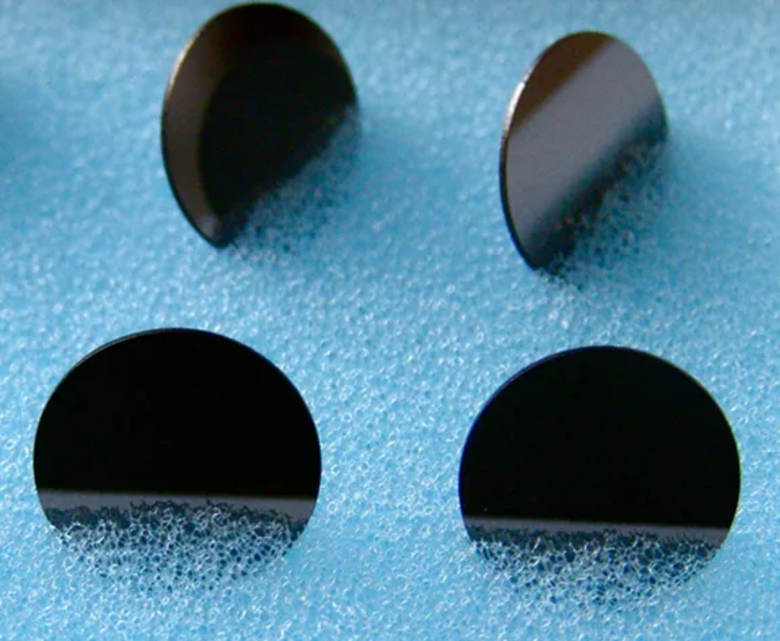

Diamond plates

The application of diamond wafers produced by diamond making machines, such as HPHT cubic presses, has revolutionized various industries, including manufacturing, medicine, and electronics. These lab-grown diamond machines create diamond materials with exceptional properties that make them ideal for a wide range of industrial, medical, and electrical applications.

Industrial Applications

In the manufacturing industry, diamond wafers produced by diamond press machines have become indispensable for cutting, grinding, and polishing tools. The extreme hardness and wear resistance of diamonds make them perfect for machining tough materials like ceramics, hardened steel, and composite materials.

Application in Electronics

In the electronics industry, diamond wafers produced by HPHT cubic presses have the potential to transform the way we design and manufacture electronic devices. Diamond's wideband gap, high thermal conductivity, and excellent electrical insulation properties make it an ideal material for high-power, high-frequency, and high-temperature applications. Diamond wafers are being used to develop advanced semiconductor devices, such as power transistors and diodes, which can operate at higher voltages, currents, and temperatures than traditional silicon-based devices. This could lead to more efficient, compact, and reliable electronic systems for applications ranging from renewable energy to electric vehicles.

Diamond's unique optical and thermal properties make it suitable for use in advanced optoelectronics devices, such as high-brightness LEDs and laser diodes. By incorporating diamond materials into these devices, manufacturers can achieve higher output powers, improved heat dissipation, and longer lifetimes, enabling the development of more efficient and reliable lighting and laser systems.

How to Choose a Hydraulic Press Machine?

When selecting a cubic press, buyers must understand their production goals upfront - whether for industrial diamond powder, HPHT rough diamond growth, diamond enhancement or tool-grade diamonds. The press configuration and technical specifications can then be tailored accordingly.

For example, producing single-crystal diamonds requires precise, sustained pressure control over longer growth cycles, necessitating advanced electronics. Conversely, industrial diamond synthesis involves shorter cycles and simpler pressure parameters, lowering control panel requirements. Configuration directly impacts system pricing and return on investment.

The cubic press promises to accelerate the adoption of lab-grown diamonds globally. With heightened production volumes, improved crystal quality and lower operating costs compared to older HPHT technologies, the cubic press helps lab diamond producers meet rising market demand. As the premier HPHT solution, it will shape the future trajectory of the created diamond industry worldwide.

HPHT Cubic Press Machines by Labrilliante

For US entities keen to tap the lucrative lab diamond market, Labrilliante offers customizable HPHT solutions scalable to any production volume. Our catalog features diverse automated presses boasting advanced pressure and temperature controls for mass manufacturing brilliant, flawless crystals. By buying our cubic systems online, companies worldwide can benefit from tailored equipment specifications, rapid order fulfillment and dedicated customer support - getting set up for commercial lab diamond production.

Get Prices and Availability

FAQs

An HPHT cubic press machine is equipment used for synthetic diamond production that employs the high-pressure, high-temperature (HPHT) method to create synthetic diamonds. This diamond cubic press is a key component in the process of producing lab-grown diamonds.

HPHT cubic press machines can also be used to produce other ultra-hard materials such as cubic boron nitride (cBN) and polycrystalline diamond (PCD). These materials are widely used in industrial applications due to their exceptional hardness, wear resistance, and thermal stability. HPHT diamond equipment can be adapted to create these materials by adjusting the pressure, temperature, and catalyst used in the process.

A cubic press creates the high-pressure and high-temperature conditions necessary to transform graphite into diamond. The graphite is placed in a high-pressure chamber where it is subjected to pressures up to 60,000 atmospheres and heated to temperatures around 1500°C. These extreme conditions lead to the formation of a synthetic diamond.

It can produce CVD diamond precursors but not finalize crystals. HPHT and CVD remain distinct methods.

Yes, techniques like color alteration rely extensively on specialized cubic press capabilities.

You you can contact local suppliers of lab diamond production equipment or search online catalogs and directories. Labrilliante is a supplier of HPHT equipment and provides worldwide shipping.

The cost of a cubic press can vary significantly depending on factors such as its type, size, production capacity, and level of automation. Contact us to find out the price of the cubic press model you need.

Wooden containers with water/oil-resistant coatings safely mobilize materials as per client needs.

By empowering unmatched experimentation, HPHT cubic press systems will steer strategic innovations across industries for years ahead.

Cubic press machines have a wide range of industrial applications. This equipment шы employed in the electronics industry for heat dissipation in high-power devices, such as in AI and cloud computing. HPHT equipment is used in research and development for creating novel materials with unique properties, like GaN-on-Diamond semiconductors for wireless communication, which offer increased power density, improved reliability, and superior high-frequency performance.