What Diamond Cut means for 4C

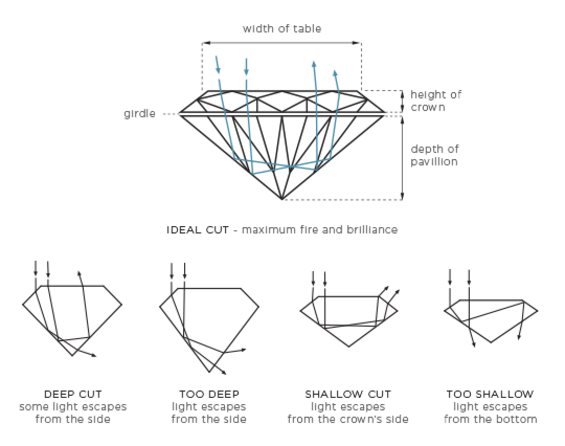

Cut is the most important property out of all the diamond’s 4C’s and is the only one which is completely determined by the skill of the diamond cutter, and not the way the stone was grown. The quality of the cut reflects the equilibrium of symmetry, polish and proportions. It affects the overall look of the gemstone and its light performance (the balance of brilliance, fire and scintillation). The better the diamond is cut, the larger and more sparkly and beautiful it appears.

Cut grade

The grade of the cut only applies to the Round Brilliant diamonds, as this is the only shape that has the standard which allows for the best light performance of the stone. Cut quality of both mined and lab-grown diamonds is graded in the same way by the gemological institutes. It is determined by the light performance and the symmetry and polishing defects that the gemstones might have. The GIA cut grading system is mostly applied across the industry:

- Excellent Cut: the highest standards of proportions and polish, the biggest possible light return and the exquisite scintillation; any defects in symmetry and polish can be barely seen with a 10x loupe.

- Very Good Cut: well-balanced proportions and great polishing, high levels of light return and light performance: some defects can be detected with a 10x loupe.

- Good Cut: the symmetry and proportions of the diamond might be less well-balanced which affects the levels of light return and quality of light performance; defects are visible with a 10x loupe.

- Fair Cut: symmetry and proportions of the stone are poorly balanced, but it still reflects some light, defects of symmetry and polishing process are obvious under the loop and can be seen with a naked eye.

- Poor Cut: unbalances proportions, almost no light return or light performance, any defects are easily determined by a naked eye.

The best diamond proportions

| Shape | Depth % | Table % | Girdle | Culet | L to W Ratio |

|---|---|---|---|---|---|

| Round Brilliant Cut | 59 – 62.6% | 54 – 57% | Thin-Slightly Thick | None-Pointed | 1.0 – 1.03 |

| Princess Cut | 68 – 74% | 69 – 75% | Thin-Slightly Thick | None-Pointed | 1.0 – 1.04 |

| Cushion Cut | 61 – 68% | < 68% | Thin-Slightly Thick | None-Pointed | 1.0 – 1.08 (sq) 1.15 – 1.25 (rect) |

| Emerald Cut | 61 – 68% | 61 – 69% | Thin-Slightly Thick | None-Pointed | 1.30 – 1.45 |

| Asscher Cut | 61 – 68% | 61 – 69% | Thin-Slightly Thick | None-Pointed | 1.0 – 1.05 |

| Oval Cut | < 63% | 53 – 63% | Thin-Slightly Thick | None-Pointed | 1.30 – 1.50 |

| Pear Shape | < 68% | 53 – 65% | Thin-Slightly Thick | None-Pointed | 1.45 – 1.75 |

| Radiant Cut | < 67% | 61 – 69% | Thin-Slightly Thick | None-Pointed | 1.0 – 1.05 (sq) 1.20 – 1.50 (rect) |

| Heart Shape | 56 – 66% | 56 – 62% | Thin-Slightly Thick | None-Pointed | 1.0 (or as close as possible) |

| Marquise Cut | 58 – 62% | 53 to 63% | Thin-Slightly Thick | None-Pointed | 1.85 – 2.1 |

Hearts and Arrows

Heart and Arrows pattern appears in ideally cut Round Brilliant diamonds. It is a facet pattern of eight arrows that can be seen from a table-up view, and eight small hearts that are visible from the pavilion. A simple light reflector is required to see the hearts and arrows completely, but they can also be visible to a naked eye if a source of good lighting is present. Diamonds with hearts and Arrows patterns have the best proportions and alignment of the facets, which creates the best light performance for the viewer.

Russian Cut

The term "Russian cut" includes the origin of the diamond, and the cutting process it undergoes.

It used to apply to the diamonds, which were mined and cut in Russia - since the import and export of rough diamonds underwent restrictions from the Russian government, the cutting process had to be done beforehand. At the same time, the policies of Russian cutters became “quality over quantity”. It was a standard to sacrifice the yield to get the best quality a diamond can be, since the better cut diamond will always look bigger. This philosophy made Russian diamonds famous across the world for their exceptional light performance. LaBrilliante upholds this philosophy and always strives to get the best quality.

Cutting Process

Diamond cutters are the artisans who turn a rough piece of material into a polished gemstone. Cutting process is a hard step-by-step enterprise which needs to be done with precise care. It consists of 7 general steps:

1. Pre-Process Sorting

2. Planning and Marking

4. Bruting

5. Blocking

6. Brillianteering

7. Final Quality Check and Re-polishing

Cutting process requires both manual labor and state-of-the-art technology, but it is the skill of the masters that determines the quality of the finished gemstone. This is why LaBrilliante employs only the most skillful masters of their craft to bring the perfect diamonds from our rough to your reality.