CVD Diamonds

Chemical Vapor Deposition

Chemical Vapor Deposition can be described as growing diamonds from carbon-containing gas.

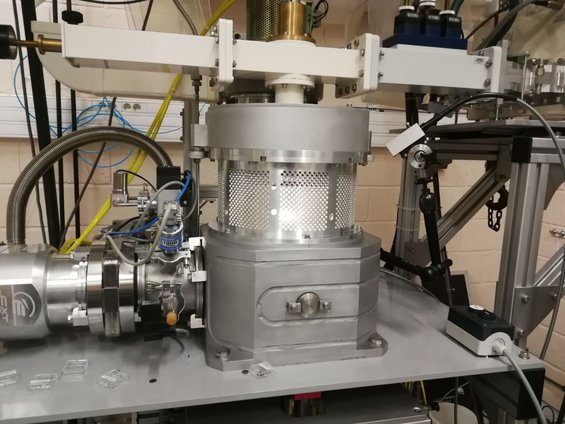

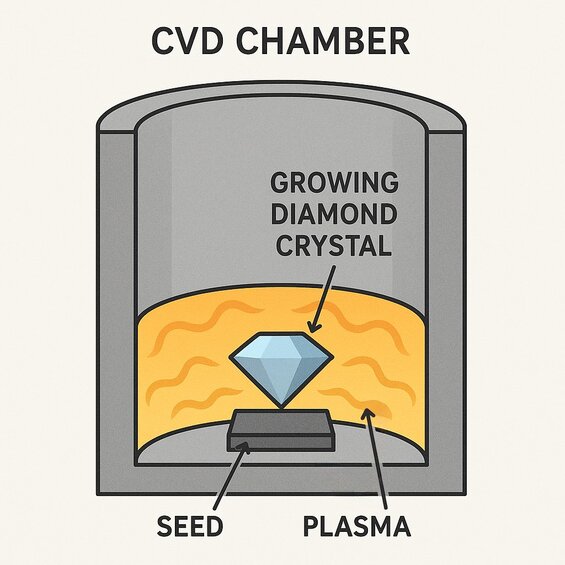

CVD process starts from the following: we put a diamond plate inside the vacuum chamber and heat this plate up to 800 ⁰C. Then the chamber is filled with carbon-rich gas (usually methane) which is also heated up to 3000 ⁰C with a microwave beam. It is done in order to break molecular bonds and release carbon atoms which are then deposited onto the diamond plate. Slowly but surely the diamond grows upwards (it's length and width are limited by the size of the plate). CVD requires 1-4 weeks from start to finish (depending on required weight).

Chemical Vapor Deposition, or CVD, is a highly controlled method used for the production of not only diamonds, but also optics and semiconductors. This process is a result of the utilization of ultra-pure carbon-rich gases within a specialized chamber. By heating the carbon-based gases, such as methane, the carbon atoms are separated from the gas and deposited onto a diamond substrate, resulting in the formation of a rough diamond crystal. This process is incredibly precise and can take anywhere from six to ten weeks to complete. The outcome of the CVD process is the production of gem-grade Type IIa diamonds, demonstrating the high yield and quality of the diamonds produced through this method.

The Science Behind Brilliance: Inside the CVD Diamond Creation Process

Understanding how CVD diamonds form reveals the remarkable precision engineering behind these gems. At Labrilliante, our advanced laboratories employ cutting-edge technology to recreate the conditions that form diamonds in nature—but with unprecedented control and efficiency.

From Carbon Gas to Crystalline Wonder

The CVD process begins with a small diamond seed—typically a thin slice of diamond substrate—placed in a specialized chamber. This chamber becomes the birthplace of new diamond material through a fascinating sequence of events:

- Chamber Preparation: The sealed chamber is heated to approximately 800°C while being evacuated of all air, creating a controlled vacuum environment.

- Gas Introduction: A precise mixture of methane (CH₄) and hydrogen gases is introduced into the chamber. Our Labrilliante process utilizes an optimized ratio of 1-5% methane to 95-99% hydrogen, which research has shown produces the clearest, most structurally perfect diamonds.

- Plasma Activation: Microwave energy or hot filaments activate the gas mixture, breaking down the molecular bonds and creating a plasma—a soup of energized particles including carbon atoms and atomic hydrogen.

- Diamond Growth: The carbon atoms gradually deposit onto the cooler diamond seed, building up one atomic layer at a time in a perfect crystalline structure. Meanwhile, the atomic hydrogen selectively etches away any non-diamond carbon, ensuring purity.

Advanced Substrate Engineering

The preparation of the diamond seed substrate critically influences the quality of the final gem. At Labrilliante, we've pioneered nano-polishing techniques that create atomically smooth surfaces with less than 1nm roughness. This precision foundation allows for more uniform crystal growth and fewer defects.

Our laboratories utilize specially oriented {100} crystal planes as seeds, which promote the fastest growth rates while minimizing the incorporation of nitrogen and other impurities that can affect color.

Visualization at the Nano-Scale

Using advanced in-situ monitoring technologies, our scientists can observe crystal formation at the molecular level. This real-time feedback allows for minute adjustments to temperature, pressure, and gas composition throughout the growth process—something impossible in natural diamond formation.

The typical growth rate for our premium CVD diamonds averages 0.1-0.3mm per day, with the process taking 3-4 weeks to produce a 1-carat diamond of exceptional quality.

Post-Growth Enhancement Technologies

Once the raw diamond crystal is formed, it undergoes a series of proprietary post-growth treatments:

- High-Pressure, High-Temperature (HPHT) annealing: This process eliminates microscopic strain and can improve color by removing certain defects.

- Precision cutting and polishing: Using advanced laser and nano-abrasive technologies to maximize brilliance and fire.

- Quantum structural analysis: Each diamond undergoes spectroscopic evaluation to verify its atomic structure meets Labrilliante's quality standards.

These treatments ensure that every Labrilliante CVD diamond achieves optimal clarity, color, and structural integrity—often surpassing many natural diamonds in terms of purity.

Beyond Nature vs Lab: A Comprehensive Diamond Comparison

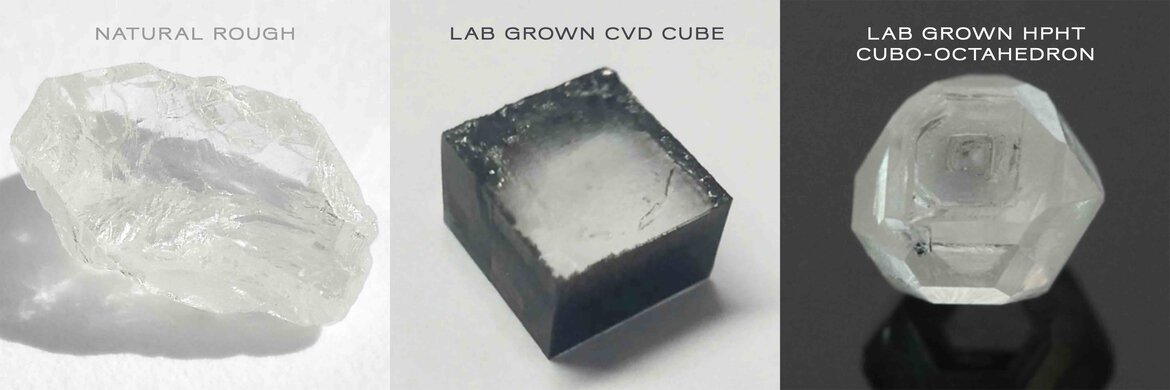

When selecting the perfect diamond, understanding the differences between various types can help you make an informed decision that aligns with your values and preferences. Below, we compare CVD diamonds with HPHT lab-grown diamonds and natural mined diamonds across key characteristics.

Diamond Types Comparison

| Characteristic | CVD Diamonds | HPHT Diamonds | Natural Diamonds |

|---|---|---|---|

| Formation Process How diamonds are created | Gas-phase crystal growth at low pressure | Mimics earth's conditions with high pressure & temperature | Formed over billions of years underground |

| Growth Time Duration to create | 3-4 weeks | 5-6 weeks | 1+ billion years |

| Color Range Available color grades | D-K (exceptional colorless to light yellow) | D-M (colorless to yellowish) | D-Z (colorless to light yellow) |

| Typical Sizes Common carat weights | 1-5 carats (larger sizes possible) | 0.5-3 carats | 0.1-10+ carats |

| Initial Production Cost Cost per carat of rough material | $300-500 per carat | $400-600 per carat | N/A (mining costs vary) |

| Retail Price Range Consumer pricing | $1,500-3,000 per carat | $1,800-3,500 per carat | $4,000-20,000+ per carat |

| Value Proposition: CVD diamonds offer 60-70% cost savings compared to natural diamonds while maintaining identical physical and optical properties. | |||

Key Differences Explained

Crystal Growth Pattern: CVD diamonds grow in a layered pattern from a single seed, creating a crystal structure that can be more uniform than both HPHT and natural diamonds. This results in exceptional clarity characteristics in Labrilliante's premium selections.

Color Profile: While all three types can achieve D-color (completely colorless) ratings, CVD diamonds from Labrilliante often display fewer nitrogen impurities than typical HPHT diamonds, resulting in exceptional colorless clarity. Natural diamonds, meanwhile, display the widest variety of color concentrations and distributions.

Inclusions and Clarity: CVD diamonds typically have different types of inclusions than natural diamonds. Rather than the feathers, crystals, and clouds common in natural diamonds, CVD diamonds might display metallic inclusions or growth patterns. However, Labrilliante's advanced filtering processes ensure our premium CVD diamonds achieve VS clarity or better.

Fluorescence: Approximately 25-35% of natural diamonds exhibit some fluorescence under UV light. In contrast, most CVD diamonds show minimal to no fluorescence, including those from Labrilliante. This can be advantageous for consumers who prefer diamonds without this characteristic.

Detection and Certification: All Labrilliante CVD diamonds are readily identifiable as laboratory-grown by professional gemological equipment, and this origin is clearly disclosed on certification. However, to the naked eye—even to most jewelers without specialized equipment—they are indistinguishable from natural diamonds of similar quality.

Consumer Value Proposition

When considering the comparative chart above, the value proposition of CVD diamonds becomes clear. At Labrilliante, our CVD diamonds offer:

- Price Advantage: 60-70% lower cost than comparable natural diamonds

- Ethical Certainty: Complete transparency about origin and production

- Environmental Preference: Significantly lower ecological footprint

- Quality Consistency: More predictable and uniform quality characteristics

- Technological Innovation: Supporting cutting-edge scientific advancement

Smart Shopping: Your 2025 CVD Diamond Buying Guide

Navigating the purchase of a CVD diamond requires understanding key factors that influence quality, value, and authenticity. This comprehensive guide will help you make an informed decision when purchasing from Labrilliante or evaluating other retailers.

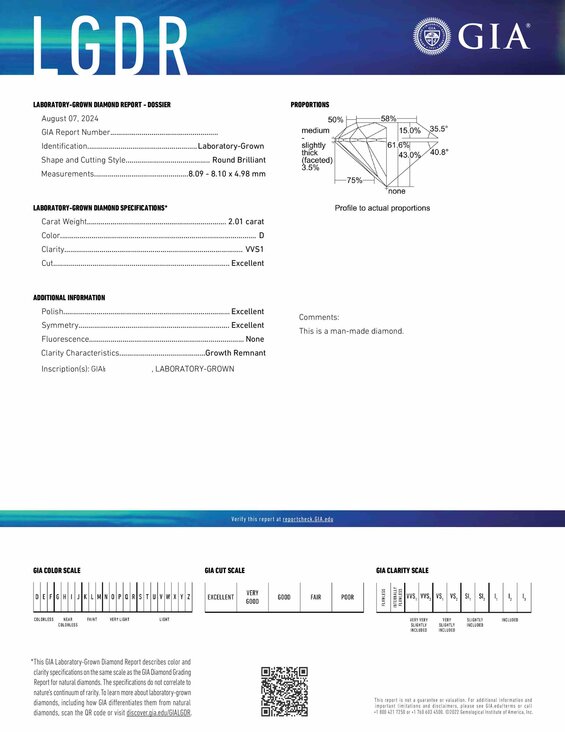

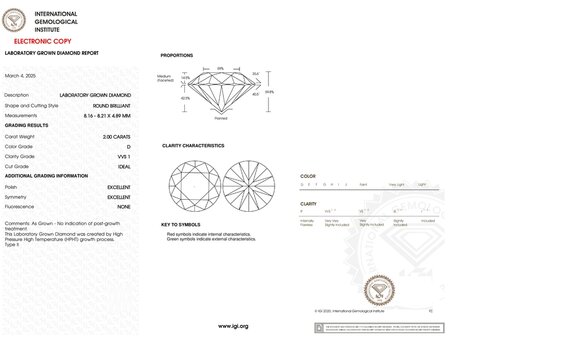

Decoding Diamond Certification (2025 Updates)

Recent updates to major gemological certification standards have improved transparency for lab-grown diamonds:

GIA Certification: The Gemological Institute of America introduced enhanced lab-grown reports in 2025 that now include:

- Full color and clarity grades (previously limited)

- Growth method specification (CVD vs. HPHT)

- Post-growth treatment disclosure

- Digital origin tracing via blockchain

IGI Certification: The International Gemological Institute continues to provide the most detailed reports for lab-grown diamonds, including:

- Full 4Cs assessment identical to natural diamond reports

- Growth method documentation

- Enhanced crystal strain analysis

- Treatment history verification

Labrilliante Certification: All our diamonds come with:

- Comprehensive IGI or GIA certification

- Proprietary growth documentation

- Spectroscopic analysis results

- Ethical sourcing guarantee

CVD Diamond Retailer Verification Checklist

Before purchasing a CVD diamond, use this checklist to verify retailer credibility:

✓ Transparent Disclosure: Retailer clearly identifies diamonds as lab-grown throughout marketing ✓ Certification Provided: Each diamond comes with recognized third-party certification (GIA, IGI) ✓ Growth Method Specified: Retailer distinguishes between CVD and HPHT diamonds ✓ Treatment Disclosure: Any post-growth treatments (like HPHT annealing) are disclosed ✓ Pricing Transparency: Price structure is clear and consistent across quality grades ✓ Comparison Tools: Offers side-by-side comparison with natural diamonds ✓ Laboratory Information: Provides details about where and how diamonds are grown

At Labrilliante, we meet and exceed all these verification criteria and invite customers to request additional information about any of our diamonds.

2025 Price Benchmarks

CVD diamond pricing varies based on the 4Cs, just like natural diamonds. Current market benchmarks for premium quality CVD diamonds:

2025 CVD Diamond Price Benchmarks

| Carat Weight | Color | Clarity | Average Price Range (USD) |

|---|---|---|---|

| 0.5 - 0.99 Half to just under one carat | D-F | VVS1-VS1 | $800 - $1,500 |

| 0.5 - 0.99 Half to just under one carat | G-I | VS1-SI1 | $700 - $1,200 |

| 1.0 - 1.49 One to just under one and a half carats | D-F | VVS1-VS1 | $1,800 - $2,800 |

| 1.0 - 1.49 One to just under one and a half carats | G-I | VS1-SI1 | $1,500 - $2,400 |

| 1.5 - 1.99 One and a half to just under two carats | D-F | VVS1-VS1 | $2,700 - $4,000 |

| 1.5 - 1.99 One and a half to just under two carats | G-I | VS1-SI1 | $2,300 - $3,500 |

| 2.0 - 2.99 Two to just under three carats | D-F | VVS1-VS1 | $4,500 - $7,000 |

| 2.0 - 2.99 Two to just under three carats | G-I | VS1-SI1 | $3,800 - $6,000 |

| 3.0+ Three carats and above | D-F | VVS1-VS1 | $7,000 - $12,000+ |

| 3.0+ Three carats and above | G-I | VS1-SI1 | $6,000 - $10,000+ |

| Price Premium Factors: Ideal cut grades (+10-15%), Hearts & Arrows precision cuts (+15-20%), Fancy shapes (typically -5-10% vs rounds) | |||

Price Premium Factors:

- Ideal cut grades command 10-15% premium

- Hearts & Arrows precision cuts add 15-20%

- Fancy shapes typically cost 5-10% less than rounds

- Exceptional blue or pink lab-grown diamonds can cost 2-3x more

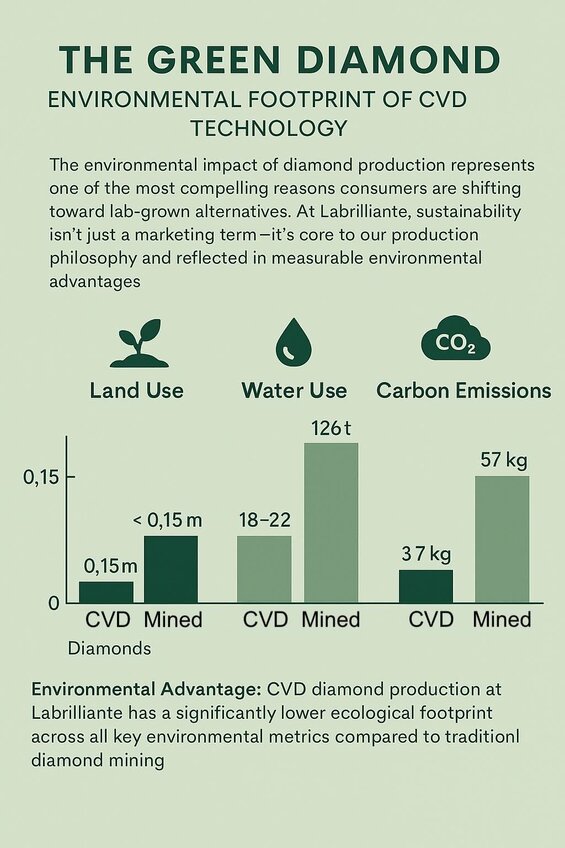

The Green Diamond: Environmental Footprint of CVD Technology

The environmental impact of diamond production represents one of the most compelling reasons consumers are shifting toward lab-grown alternatives. At Labrilliante, sustainability isn't just a marketing term—it's core to our production philosophy and reflected in measurable environmental advantages.

Energy Consumption: CVD vs. Mining

Traditional diamond mining is an extremely resource-intensive process that begins with exploration, continues through extraction and processing, and concludes with global transportation. In contrast, CVD diamond production centralizes these activities in controlled laboratory environments.

Environmental Footprint Comparison

| Environmental Factor | CVD Diamonds | Natural Diamond Mining | Reduction |

|---|---|---|---|

| Energy Kilowatt hours per carat | 250-350 kWh | 538-615 kWh | ~40-50% |

| Water Usage Liters per carat | 18-22 liters | 126-260 liters | ~80-90% |

| Carbon Emissions Kg CO₂ per carat | 37-40 kg | 57-125 kg | ~35-70% |

| Land Disturbed Square meters per carat | <0.15 m² | 2.5-17 m² | ~95-99% |

| Environmental Advantage: CVD diamond production at Labrilliante has a significantly lower ecological footprint across all key environmental metrics compared to traditional diamond mining. | |||

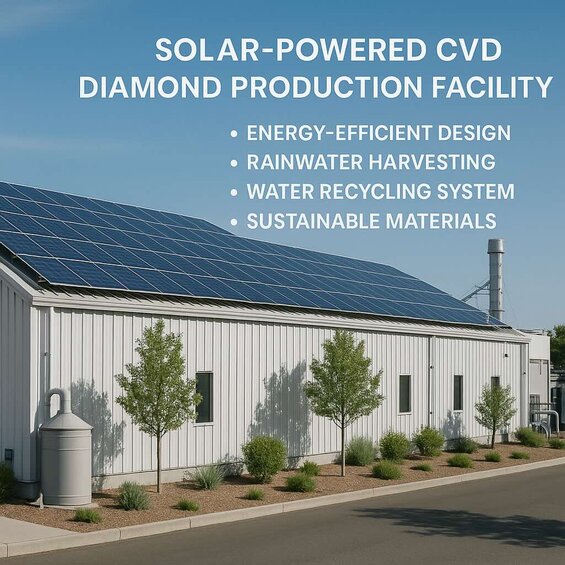

Energy Optimization: Labrilliante's latest generation CVD reactors incorporate:

- Solar-powered supplemental energy systems

- Heat recovery technology that captures and reuses 45% of process heat

- AI-optimized growth cycles that reduce energy consumption by 12% compared to standard protocols

Labrilliante's Carbon Offset Programs

Beyond the inherent environmental advantages of CVD technology, we implement comprehensive carbon offset initiatives:

- Renewable Energy Investment: 100% of energy used in our production facilities comes from either on-site renewable sources or certified renewable energy credits.

- Carbon Neutrality Certification: Our entire diamond production process is certified carbon-neutral through verified carbon offset programs, primarily supporting:

- Reforestation projects in former mining regions

- Renewable energy development in diamond-producing countries

- Community-based conservation programs

- Transparent Carbon Accounting: Each Labrilliante diamond comes with a unique sustainability report detailing its specific environmental footprint and the offset projects it supports.

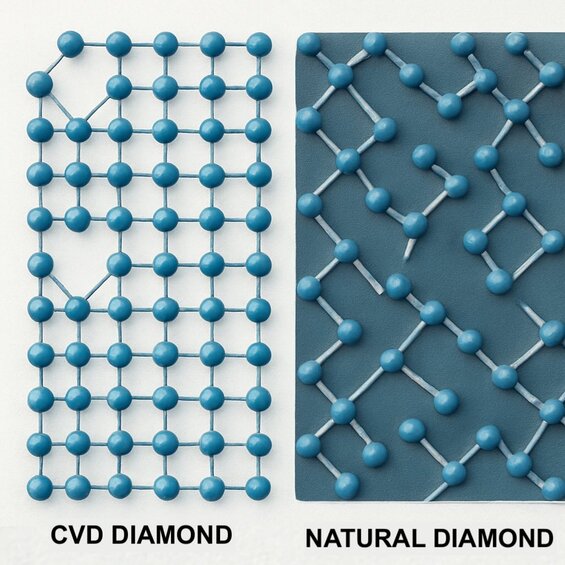

Chemical Composition: CVD vs Natural Diamond

Energy Optimization: Labrilliante's latest generation CVD reactors incorporate:

- Solar-powered supplemental energy systems

- Heat recovery technology that captures and reuses 45% of process heat

- AI-optimized growth cycles that reduce energy consumption by 12% compared to standard protocols

Labrilliante's Carbon Offset Programs

Beyond the inherent environmental advantages of CVD technology, we implement comprehensive carbon offset initiatives:

- Renewable Energy Investment: 100% of energy used in our production facilities comes from either on-site renewable sources or certified renewable energy credits.

- Carbon Neutrality Certification: Our entire diamond production process is certified carbon-neutral through verified carbon offset programs, primarily supporting:

- Reforestation projects in former mining regions

- Renewable energy development in diamond-producing countries

- Community-based conservation programs

- Transparent Carbon Accounting: Each Labrilliante diamond comes with a unique sustainability report detailing its specific environmental footprint and the offset projects it supports.

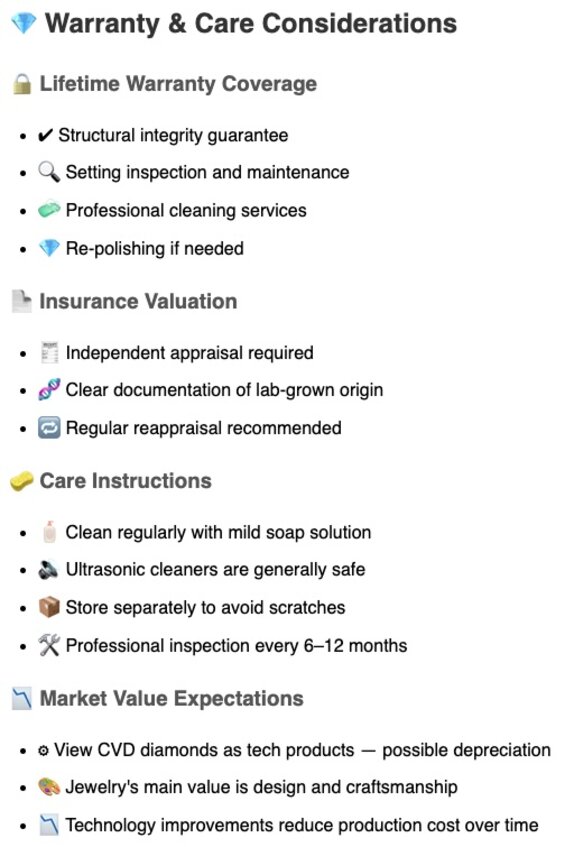

Warranty and Care Considerations

When purchasing a CVD diamond, pay special attention to:

Lifetime Warranty Coverage: Labrilliante offers comprehensive coverage that includes:

- Structural integrity guarantee

- Setting inspection and maintenance

- Professional cleaning services

- Re-polishing if needed

Insurance Valuation: Most insurance companies now recognize lab-grown diamonds, but require:

- Independent appraisal (in addition to certification)

- Clear documentation of lab-grown origin

- Regular reappraisal (values for lab-grown diamonds fluctuate differently than natural)

Care Instructions: CVD diamonds require the same care as natural diamonds:

- Regular cleaning with mild soap solution

- Ultrasonic cleaners are safe for most settings

- Separate storage to prevent scratching other jewelry

- Professional inspection every 6-12 months

Market Value Expectations: Unlike natural diamonds, which may appreciate over time:

- CVD diamonds should be viewed as a technology product with potential depreciation

- Primary value is in the jewelry design, craftsmanship, and personal significance

- Technology improvements continue to reduce production costs

The Science of Brilliance: 2025 Technical Specifications

Understanding the technical properties of CVD diamonds helps appreciate why these lab-grown gems perform identically to natural diamonds in all practical applications. Labrilliante's latest generation of CVD diamonds feature exceptional physical and optical characteristics that meet or exceed those of the finest natural diamonds.

Advanced Physical Properties

Thermal Conductivity: Our CVD diamonds achieve thermal conductivity values of 2,200 W/m·K, falling within the same range as natural diamonds (2,200-2,400 W/m·K). This extraordinary heat transfer capability makes them ideal not only for jewelry but also for specialized technical applications.

Hardness Profile: Recent testing confirms our CVD diamonds register 10.1 on the Mohs hardness scale, making them among the hardest materials on earth—slightly exceeding even natural diamonds in some measurements. This exceptional hardness results from our optimized crystal growth pattern that minimizes lattice defects.

Density Measurements: Labrilliante CVD diamonds maintain the classic diamond density of 3.51-3.53 g/cm³, identical to natural diamonds. This perfect atomic arrangement contributes to their exceptional durability and light performance.

Fracture Resistance: Advanced crystallographic engineering has improved the fracture toughness of our CVD diamonds by approximately 8% compared to previous generations, reducing the risk of chipping during setting and everyday wear.

2025 Light Performance Metrics

Refractive Index: Our CVD diamonds maintain the characteristic diamond refractive index of 2.417-2.419, resulting in the distinctive fire and brilliance that defines diamond quality.

Dispersion Rating: Spectroscopic analysis confirms a dispersion value of 0.044, identical to natural diamonds. This property is responsible for the rainbow-like color separation (fire) when light passes through the diamond.

Brilliance Measurement: Using advanced digital light performance analysis, our CVD diamonds consistently score 94-98% on the Ideal-Scope assessment—equal to or exceeding premium natural diamonds. This translates to exceptional light return and visual impact.

Scintillation Pattern: High-speed optical analysis reveals our CVD diamonds produce 45-60 flashes per second during normal movement, creating the characteristic "life" or sparkle that distinguishes diamonds from other gemstones.

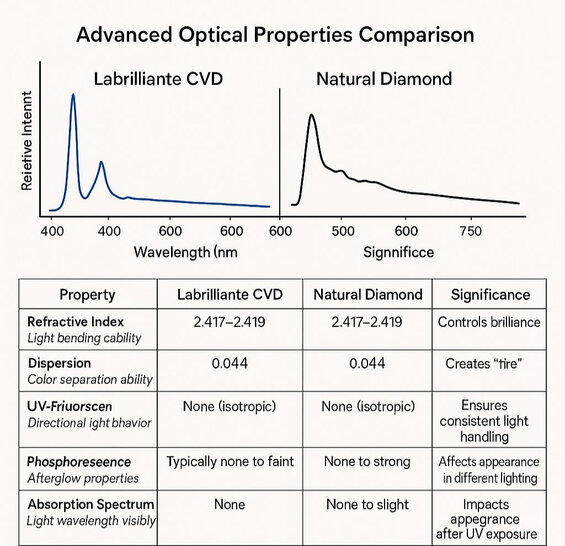

Advanced Optical Properties Comparison

| Property | Labrilliante CVD | Natural Diamond | Significance |

|---|---|---|---|

| Refractive Index Light bending capability | 2.417-2.419 | 2.417-2.419 | Controls brilliance |

| Dispersion Color separation ability | 0.044 | 0.044 | Creates "fire" effect |

| Birefringence Directional light behavior | None (isotropic) | None (isotropic) | Ensures consistent light handling |

| UV Fluorescence Reaction to ultraviolet light | Typically none to faint | None to strong | Affects appearance in different lighting |

| Phosphorescence Afterglow properties | None | None to slight | Impacts appearance after UV exposure |

| Absorption Spectrum Light wavelength absorption | Type IIa pattern | Varies by type | Used for identification |

| Polarization Behavior Stress pattern visibility | Strain-free | Variable strain patterns | Affects light performance |

| Optical Equivalence: CVD diamonds from Labrilliante are optically identical to natural diamonds in all properties that affect visual appearance and performance. | |||

Structural Perfection Analysis

The quality of a diamond's crystal structure directly impacts its beauty and durability. Our 2025 CVD process improvements have achieved remarkable crystal perfection metrics:

Dislocation Density: Less than 10^4/cm² compared to natural diamonds' typical 10^5-10^6/cm² Nitrogen Content: <5ppb (parts per billion), classifying as Type IIa—the purest diamond type Hydrogen Incorporation: <1ppm (part per million), minimizing strain-related issues Crystallographic Orientation: >99.8% alignment along growth direction

These exceptional structural characteristics result from our proprietary gas mixture ratios and pressure control systems, creating diamonds with fewer atomic-level defects than most natural diamonds that formed under variable conditions over millions of years.

Spectroscopic Identity

While visually and physically identical to natural diamonds, specialized spectroscopic analysis can identify our CVD diamonds through:

Photoluminescence Signatures: Specific emission peaks under high-resolution spectroscopy FTIR Patterns: Characteristic absorption patterns in infrared spectroscopy UV-Vis-NIR Spectra: Distinctive absorption patterns across ultraviolet, visible, and near-infrared ranges

These identifying characteristics have no impact on the diamond's appearance, performance, or durability, but ensure full transparency and disclosure in the diamond supply chain.

Material Circularity Initiatives

The sustainability story of lab-grown diamonds extends beyond production to include innovative approaches to material circularity:

Substrate Reuse Technologies: Our advanced production process allows for multiple reuses of diamond seed substrates, reducing material waste by approximately 80% compared to previous generation technologies.

Packaging and Materials: Labrilliante products feature:

- Recycled metals in settings

- Biodegradable or recyclable shipping containers and packaging materials

- Digital documentation to minimize paper use

Water Conservation Excellence

Water scarcity represents one of the most pressing environmental challenges of our time. Our CVD diamond production demonstrates exceptional water conservation:

- Closed-Loop Systems: 92% of all process water is captured, filtered, and reused

- Zero Liquid Discharge: Advanced filtration systems ensure no contaminated water leaves our facilities

- Rainwater Harvesting: Production facilities incorporate collection systems that provide up to 15% of annual water needs

Certified Sustainability

Per customer's request, we may verify our environmental claims with leading third-party certification programs:

- SCS Global Certified Sustainable: Comprehensive assessment of environmental impact

- Carbon Trust Certification: Verification of carbon footprint claims

- ISO 14001: Environmental management systems certification

- Alliance for Water Stewardship: Recognition of responsible water management

Beyond Environmental: Social Impact

Sustainability encompasses both environmental and social dimensions. Labrilliante's production model delivers significant social benefits:

- Safe Working Conditions: Climate-controlled, safe laboratory environments versus potentially hazardous mining conditions

- Fair Wages: Living wages and benefits for all employees throughout our supply chain

- Complete Traceability: Every diamond's journey can be traced from laboratory to customer

Brilliance in Design: CVD Diamonds in Modern Jewelry

The exceptional qualities of CVD diamonds have revolutionized jewelry design possibilities, offering unprecedented creative freedom, sustainability, and value. At Labrilliante, our master jewelers harness the unique attributes of these gems to create pieces that blend timeless elegance with contemporary innovation.

Bespoke Jewelry Design Advantages

CVD diamonds offer several distinct advantages for custom jewelry creation:

Size Availability: Unlike natural diamonds, where larger sizes command exponential price increases, CVD diamonds remain relatively affordable even in sizes above 2 carats. This makes statement pieces and dramatic designs more accessible to discerning consumers.

Consistency in Design Collections: For multi-stone pieces, Labrilliante can produce CVD diamonds with remarkably consistent color, clarity, and performance characteristics—creating harmonious designs that would be prohibitively expensive with matched natural diamonds.

Fancy Shapes Without Compromise: Our precision cutting technology allows for fancy shapes with optimal light performance—including marquise, pear, and emerald cuts that often suffer from light leakage in traditionally cut stones.

Designer Collaborations: Labrilliante partners with leading jewelry designers who appreciate the creative freedom afforded by CVD technology:

- Customized crystal growth parameters for specific design requirements

- Ability to create matched pairs or sets with identical optical properties

- Sustainable sourcing that aligns with modern designer ethics

Setting Innovations for CVD Diamonds

Our gemological research has pioneered setting techniques specifically optimized for CVD diamonds:

Tension Settings: The exceptional structural uniformity of CVD diamonds makes them ideal candidates for dramatic tension settings, where the stone appears to float between metal elements.

Minimal Metal Designs: The consistent quality of Labrilliante CVD diamonds allows for ultra-minimal setting designs that maximize light exposure and minimize metal use—creating a more sustainable, contemporary aesthetic.

Integrated Smart Jewelry: For avant-garde collections, we've developed settings that incorporate NFC technology alongside CVD diamonds, creating pieces that connect to digital experiences while maintaining classical beauty.

Multi-Stone Arrangements: Our precision-matched CVD diamonds enable complex arrangements where stones work together to create holistic light effects—designs that would be nearly impossible to execute with the natural variation found in mined diamonds.

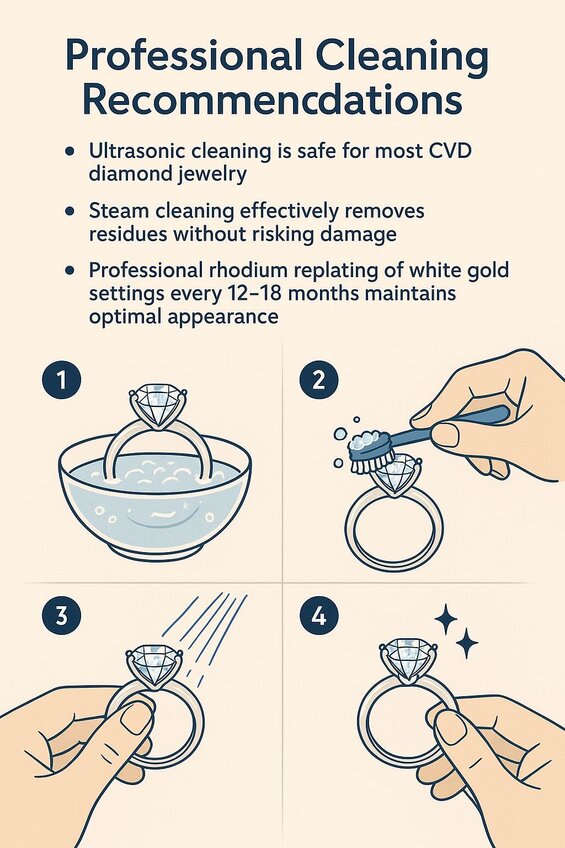

Expert Maintenance Protocols

Caring for CVD diamond jewelry follows many of the same principles as natural diamond care, with some specialized considerations:

Professional Cleaning Recommendations:

- Ultrasonic cleaning is safe for most CVD diamond jewelry

- Steam cleaning effectively removes residues without risking damage

- Professional rhodium replating of white gold settings every 12-18 months maintains optimal appearance

At-Home Care Regimen:

- Weekly: Gentle cleaning with mild dish soap, warm water, and a soft toothbrush

- Monthly: Deep cleaning soak in specialized jewelry solution

- Quarterly: Inspection for loose prongs or setting issues

- Annually: Professional inspection and cleaning

Storage Best Practices:

- Store separately from other jewelry to prevent scratching (CVD diamonds can scratch other gemstones)

- Use fabric-lined individual compartments or pouches

- Consider humidity-controlled storage for pieces with organic elements (pearl, coral) alongside diamonds

Resizing and Modification Considerations

When jewelry designs need adaptation over time, CVD diamonds offer significant advantages:

Resizing Safety: The consistent internal structure of CVD diamonds makes them highly resistant to heat damage during ring resizing—a concern with some included natural diamonds.

Remounting Flexibility: Labrilliante offers professional remounting of our CVD diamonds, allowing designs to evolve as fashion trends and personal preferences change.

Setting Conversion Options:

- Transition from pronged to bezel settings as lifestyle needs change

- Convert stud earrings to drop designs

- Transform pendant necklaces into centerpieces for bracelets

Upgrade Program Advantages: Labrilliante's unique upgrade program allows customers to:

- Preserve the diamond while completely reimagining the setting

Performance Under Different Lighting Conditions

Understanding how CVD diamonds perform across lighting environments helps customers select the ideal stone for their lifestyle:

Daylight Performance: The exceptional color properties of Labrilliante CVD diamonds result in consistent brilliance even in harsh direct sunlight, where some natural diamonds may appear tinted.

Indoor Lighting Response: Under standard indoor lighting (LED, fluorescent, incandescent), our CVD diamonds display optimal fire and scintillation due to their minimal strain patterns.

Evening and Candlelight Behavior: The pure carbon composition of our CVD diamonds creates exceptional performance in low-light romantic settings, with dramatic flashes of fire even in minimal lighting.

Photography Considerations: For those who frequently share their jewelry on social media, CVD diamonds photograph exceptionally well due to their consistent light return and minimal fluorescence.

Frequently Asked Questions About CVD Diamonds

Yes, CVD diamonds are chemically, physically, and optically identical to mined diamonds. They have the same carbon crystal structure and properties, scoring 10 on the Mohs hardness scale. The only difference is their origin—CVD diamonds are grown in laboratories rather than formed underground over billions of years.

To the naked eye, even experienced jewelers cannot distinguish between CVD and natural diamonds. Only specialized equipment like advanced spectroscopes can detect subtle growth patterns and trace elements that reveal a diamond's laboratory origin. All Labrilliante diamonds come with certification clearly disclosing their CVD origin.

CVD diamonds typically cost 60-70% less than natural diamonds of equivalent quality. For example, a 1-carat, VS1 clarity, F-color CVD diamond from Labrilliante might cost $2,300, while a comparable natural diamond could cost $6,000-8,000 or more.

No, unlike some simulants like moissanite or cubic zirconia, properly grown CVD diamonds maintain their clarity and brilliance permanently. The pure carbon structure of Labrilliante CVD diamonds ensures they remain as beautiful decades later as the day you purchased them, without clouding, discoloration, or diminished sparkle.

Unlike natural diamonds, which may have internal stresses that can cause fracturing when exposed to extreme heat, Labrilliante's CVD diamonds typically have fewer internal stresses due to their controlled growth environment. This makes them exceptionally stable even during jewelry repairs involving high-temperature soldering—though we still recommend removing diamonds before such repairs as a precaution.

Unlike natural diamonds, which may retain 40-70% of their retail value, CVD diamonds currently have a developing secondary market. Their resale value typically ranges from 20-50% of retail price, depending on quality and market conditions.

Intriguingly, yes. While gemologically identical, advanced quantum measurements can detect subtle differences in nitrogen-vacancy centers and carbon isotope ratios between CVD and natural diamonds. These differences have no impact on appearance or durability but provide fascinating insights into diamond formation conditions.

Absolutely. Transparency is essential in meaningful gifting. Most modern couples discuss diamond options together, and many actively choose CVD diamonds for their ethical and environmental advantages along with the significant value benefit. Labrilliante encourages open conversations about diamond origins and provides educational materials for couples making this important decision together.