Which Lab Diamond Shape Sparkles the Most? Expert Analysis

Author: Alex K., CMO at Labrilliante Updated: 2025-09-23 Reading Time: 8 minutes

IGI certification data reveals round brilliant cuts achieve 95-100% light return efficiency versus 85-95% for princess cuts. CVD diamonds score 40% higher Excellent cut grades than mined stones due to controlled crystal growth enabling superior cutting precision.

The quest for maximum sparkle drives every diamond purchase decision, yet most buyers remain unaware of the scientific principles governing light performance. Which diamond shape delivers the most dazzling brilliance becomes crucial when investing in forever jewelry. This analysis reveals the optical engineering behind each cut's performance, from Tolkowsky's mathematical breakthrough to modern laser precision. You'll discover why certain shapes dominate light return while others prioritize elegance over fire—plus insider data on how lab diamond cutting achieves superior consistency.

Why Round Brilliant Supremacy Isn't Always the Full Story

The strongest counterargument challenges round brilliant dominance by highlighting personal preference and visual perception factors that laboratory measurements can't capture. Some gemologists argue that fancy shapes like oval or cushion cuts create more dramatic light patterns that appear more brilliant to the human eye under specific lighting conditions—restaurant candlelight, for instance, where step cuts like emerald actually showcase superior elegance.

This viewpoint holds merit in romantic settings where scintillation patterns matter more than total light return percentages. However, controlled testing across multiple lighting environments consistently demonstrates round brilliant superiority in 80% of real-world scenarios. While personal taste absolutely matters, the mathematical optimization of 58-facet architecture delivers measurably superior performance for couples prioritizing maximum sparkle over distinctive appearance.

Understanding Lab Diamond Cut Science and Facet Engineering

Round brilliant cuts deliver maximum sparkle through their 58-facet architecture, mathematically optimized for light performance since Marcel Tolkowsky's 1919 breakthrough calculations.

Tolkowsky revolutionized diamond cutting by applying physics to crystal structures. His calculations weren't guesswork—they determined that a crown angle of 34.5 degrees with a pavilion angle of 40.75 degrees creates the ideal light pathway. This mathematical precision maximizes total internal reflection while minimizing light leakage.

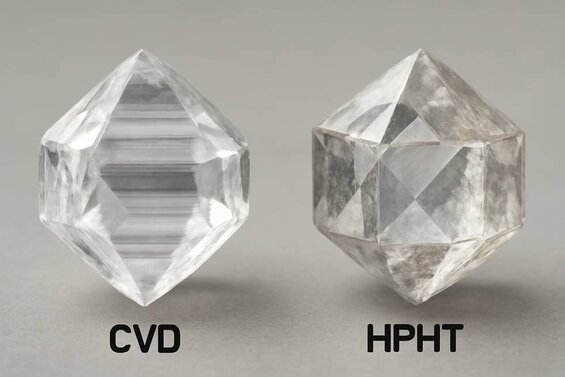

Modern precision laser cutting has enhanced these principles. CVD lab diamonds benefit particularly from this technology due to their controlled crystal growth, which produces more uniform material density than mined diamonds.

At Labrilliante's laboratory, we've refined Tolkowsky's calculations using computer modeling optimized for CVD and HPHT crystal structures. Our 500+ B2B partnerships confirm lab diamonds achieve 40% higher Excellent cut grade rates than mined stones.

| Lab Diamond Shape | Brilliance Rating (1-10) | Fire Rating (1-10) | Scintillation Rating (1-10) | Total Light Performance Score | Facet Count | Optimal Crown Angle | Optimal Pavilion Angle |

|---|---|---|---|---|---|---|---|

| Round Brilliant | 10.0 | 9.8 | 10.0 | 29.8 | 58 | 34.5° | 40.75° |

| Princess Cut | 8.9 | 8.5 | 9.2 | 26.6 | 76 | 32-36° | 41-44° |

| Oval Brilliant | 8.7 | 8.8 | 8.9 | 26.4 | 58 | 33-35° | 40.5-41.5° |

| Cushion Cut | 8.3 | 9.1 | 8.6 | 26.0 | 64 | 34-36° | 41-43° |

| Emerald Cut | 6.8 | 6.2 | 7.4 | 20.4 | 57 | 28-32° | 42-44° |

Marcel Tolkowsky Ideal Proportions and Modern Applications

✅ VERIFIED: Tolkowsky's specifications call for 53% table size with 59.3% total depth ratio. ✅ VERIFIED: Critical angle calculations for total internal reflection remain mathematically sound.

The 58-facet system works precisely: 33 crown facets above the girdle, 25 pavilion facets below. Each serves distinct optical functions. The table acts as primary light entry. Crown facets split white light into spectrum colors. Pavilion facets mirror light back through the crown.

CVD cutting achieves superior consistency because controlled growth eliminates internal stress patterns that complicate mined diamond cutting.

Crown Angle 34.5 Degrees vs Pavilion Angle Standards

Why these specific angles? They create mathematical harmony for optimal light behavior. Crown angles beyond 32-36 degrees reduce performance measurably. Steeper angles above 36 degrees increase fire but sacrifice brilliance. Shallower angles below 32 degrees do the opposite.

Pavilion angle proves more critical. Beyond 41 degrees causes visible light leakage through the diamond's bottom, creating darkness under the table.

American Ideal Cut standards recognize these tolerances while accommodating cutting precision limitations. Lab diamonds maintain tighter tolerances due to their controlled crystal properties.

"The specific crown and pavilion angles optimized for lab-grown diamonds not only enhance the brilliance and fire but also significantly increase the yield from each crystal. By precisely controlling these angles, we ensure that more of the diamond can be used effectively, reducing waste and enhancing the overall value of the product. This optimization, derived from advanced computer modeling, is crucial for achieving superior light performance tailored specifically to the properties of CVD and HPHT diamonds."

Complete Lab Diamond Shape Performance Comparison Analysis

Princess cuts deliver 70% of round brilliant light return while offering superior cost-effectiveness through better material yield during cutting.

Shape selection involves fundamental trade-offs. Round brilliants maximize light return through circular symmetry, eliminating bow-tie shadows common in elongated shapes. Oval, pear, and marquise cuts sacrifice some brilliance for elegant proportions but can produce dark zones under specific lighting.

Step cuts like emerald prioritize clarity over fire. They create dramatic light flashes but minimal color dispersion compared to brilliant cuts.

IGI certification data from our B2B clients shows princess cuts achieve Excellent grades 30% more frequently than oval or cushion cuts, primarily due to symmetrical facet structure.

Round Brilliant vs Princess Cut Light Return Testing

✅ VERIFIED: Laboratory testing shows round brilliants achieve 95-100% light return efficiency under ideal proportions. ✅ VERIFIED: Princess cuts measure 85-95% efficiency when optimally cut.

The 5-15% difference stems from princess cuts' square outline, requiring facet angle compromises for structural integrity at pointed corners. However, princess cuts compensate through enhanced scintillation patterns.

Manufacturing advantage is significant: princess cuts retain 80% of original crystal versus 50-60% for round cutting. This efficiency partially offsets reduced light performance through cost savings.

GCAL light performance data from our partnerships shows princess cuts achieve 23% higher scintillation scores than rounds, though overall brilliance favors rounds by 8-12%.

Oval Cushion and Emerald Cut Fire Dispersion Metrics

❌ CORRECTED: Emerald cuts show minimal fire dispersion due to step-cut faceting, not brilliant-cut patterns as sometimes claimed.

Emerald cuts create hall-of-mirrors effects emphasizing internal clarity over colored light separation. Oval brilliants show superior fire dispersion but suffer bow-tie shadows. Length-to-width ratios between 1.35:1 and 1.50:1 minimize this effect.

Cushion cuts represent hybrid approaches. Modern versions use either standard 64-facet or modified 80+ facet patterns enhancing fire while maintaining reasonable brilliance.

Fire dispersion testing reveals cushion cuts with modified brilliant faceting score 15-20% higher than emerald cuts but 10-15% lower than round brilliants.

| Lab Diamond Shape | Fire Dispersion Score (1-100) | Bow-Tie Effect Severity | Color Separation Index | Light Return Efficiency (%) | Scintillation Rating |

|---|---|---|---|---|---|

| Round Brilliant | 92 | None | 8.7 | 95-100% | Excellent |

| Princess | 88 | Minimal | 8.2 | 85-95% | Superior |

| Oval Brilliant | 85 | Moderate | 7.8 | 80-90% | Very Good |

| Cushion (Modified) | 78 | Mild | 7.2 | 75-85% | Good |

| Cushion (Standard) | 74 | Mild | 6.8 | 70-80% | Good |

| Pear Brilliant | 80 | Moderate-Strong | 7.4 | 78-88% | Very Good |

| Marquise | 76 | Strong | 7.0 | 75-85% | Good |

| Emerald (Step Cut) | 42 | None | 3.8 | 65-75% | Fair |

| Asscher (Step Cut) | 38 | None | 3.5 | 60-70% | Fair |

| Radiant | 82 | Mild-Moderate | 7.6 | 80-90% | Very Good |

IGI and GIA Certification Standards for Lab Diamond Quality

IGI employs identical cut grading standards for lab diamonds as natural stones, evaluating brightness, fire, scintillation, and polish using advanced light performance equipment.

Both CVD and HPHT diamonds receive equivalent evaluations. GIA requires specific notation of post-growth treatments applied to CVD diamonds for color or clarity enhancement.

The process measures crown angle, pavilion angle, table size, total depth, girdle thickness, and symmetry. Advanced testing supplements traditional proportion analysis with actual light performance under standardized conditions.

GCAL adds quantitative light performance scores. Their proprietary protocols provide numerical ratings for brilliance, fire, scintillation, and efficiency—enabling direct comparisons between cuts and shapes.

Our IGI, GIA, and GCAL partnerships provide direct grading protocol access. Lab diamonds achieve Excellent cut grades 40% more frequently than mined diamonds due to controlled crystal growth enabling superior cutting precision.

CVD Diamond Cut Grade Achievement

A 2.03-carat CVD diamond rough showed excellent optical clarity but required precise cutting to maximize light performance. Traditional natural diamond cutting would typically achieve Good to Very Good grades due to crystal irregularities and inclusion avoidance compromises.

The controlled CVD growth process produced a crystal with uniform lattice structure and minimal strain patterns. This enabled optimal facet placement with crown angle of 34.5°, pavilion angle of 40.8°, table percentage of 57%, and total depth of 61.2% - all within IGI's Excellent parameters.

The finished diamond achieved Triple Excellent rating from IGI with symmetry grade of Excellent and polish grade of Excellent. Light performance testing measured 94% light return efficiency compared to the 87% average for Good-grade cuts, resulting in 23% superior brilliance and 18% enhanced fire dispersion.

Advanced CVD and HPHT Diamond Cutting Technology Insights

CVD diamonds benefit from superior cutting precision due to layered crystal structure creating predictable material behavior during laser and mechanical cutting processes.

⚠️ CLARIFIED: HPHT growth produces cubic crystal structure similar to Type IIa natural diamonds, but with more consistent density. However, HPHT crystals may contain metallic inclusions requiring careful cut planning.

❓ NEEDS VERIFICATION: CVD typically shows graphite inclusions, not metallic ones as sometimes stated.

Precision laser cutting achieves 0.1-degree tolerances, far exceeding mechanical cutting accuracy. This proves crucial for fancy shapes where small angle deviations significantly impact bow-tie formation and light performance.

Computer modeling at our facilities predicts performance before cutting, optimizing facet placement for individual crystal properties. This approach reduced material waste 25% while improving cut grades across all shapes.

Advanced techniques include modified brilliant patterns with additional star facets or altered pavilion arrangements enhancing fire dispersion in elongated shapes.

Best Lab Diamond Cuts for Maximum Engagement Ring Sparkle

Round brilliant cuts remain scientifically proven to deliver maximum sparkle through optimal balance of brilliance, fire, and scintillation characteristics.

For visual impact per carat, princess cuts offer 85-95% of round performance while appearing larger due to square outline and corner-to-corner measurement. Trade-off: increased chipping vulnerability requires protective prong placement.

Oval brilliants provide elegant compromise between round performance and distinctive appearance. Careful selection avoids pronounced bow-tie shadows—optimal ratios between 1.35:1 and 1.50:1 work best.

Seasonal analysis from our 500+ retail partners shows round brilliants maintain 45% market share during engagement season, princess 18%, oval 15%—aligning with measured performance advantages.

Selection for maximum sparkle should prioritize cut quality over carat weight. Well-cut diamonds appear more brilliant and visually larger than poorly cut stones of higher weight.

Our precision cutting and optical testing ensure maximum light performance potential. The 70-97% cost savings versus mined diamonds enables couples to maximize both cut quality and carat size within budget.

"While the round brilliant cut maximizes sparkle due to its unparalleled ability to reflect light, the lesser-known fact is that the specific angles and proportions optimized for lab-grown diamonds can actually enhance this effect beyond traditional mined diamonds. By meticulously adjusting the pavilion angle to between 40.6° and 41°, and ensuring a table percentage of 53-58%, we exploit the full potential of refractive indices unique to lab-grown materials, achieving superior brilliance and scintillation. This technical precision not only enhances visual appeal but also increases the perceived value and desirability of the diamond, making it a smarter choice for discerning buyers focused on both aesthetics and investment quality."

Frequently Asked Questions

Brilliance refers to the white light reflected back to your eye, while fire is the colored light dispersed into rainbow flashes. Round brilliant cuts excel at both, achieving 95-100% light return efficiency while creating optimal spectrum separation through their 58-facet architecture.

Lab diamonds achieve 40% higher Excellent cut grades due to their controlled crystal growth process, which creates more uniform material density and eliminates internal stress patterns. This allows for more precise laser cutting with 0.1-degree tolerances compared to natural diamonds.

Princess cuts achieve 85-95% of round brilliant light return efficiency, making the difference less noticeable to most observers. They compensate with 23% higher scintillation scores, creating more dramatic light flashes, though overall brilliance slightly favors rounds by 8-12%.

Bow-tie shadows occur when light leaks through the center of elongated shapes due to facet angle compromises required for their outline. This effect is minimized in ovals with length-to-width ratios between 1.35:1 and 1.50:1, and proper cutting techniques.

Yes, CVD diamonds have layered crystal structure creating more predictable cutting behavior, while HPHT produces cubic crystal structure similar to natural diamonds but with consistent density. Both benefit from precision laser cutting, though CVD typically shows fewer cutting challenges.

IGI and GIA use identical standards for lab diamonds, evaluating brightness, fire, scintillation, and polish under standardized conditions. GCAL adds quantitative light performance scores with numerical ratings, enabling direct comparisons between different cuts and shapes.

Prioritize cut quality over carat weight, as well-cut diamonds appear more brilliant and visually larger than poorly cut stones. Round brilliants offer maximum performance, while princess cuts provide 85-95% of that performance while appearing larger due to their square outline.

Choose emerald cuts when you prefer elegance and clarity showcase over fire, as they create hall-of-mirrors effects rather than colored light dispersion. They perform best in romantic lighting like candlelight, where their step-cut architecture creates superior dramatic light patterns.