Understanding How Diamond Facets Control Light & Brilliance

Author: Alex K., CMO at Labrilliante Updated: 2025-09-22 Reading Time: 12 minutes

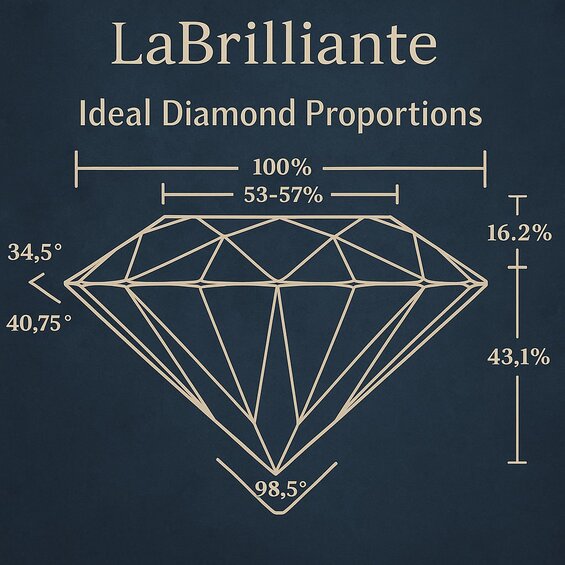

Marcel Tolkowsky's 1919 mathematical formula created the 58-facet round brilliant cut using precise 34.5° crown and 40.75° pavilion angles. Modern lab-grown diamonds achieve superior facet precision through controlled CVD/HPHT growth, enabling tighter tolerances than mined stones. Ray tracing technology now validates century-old calculations while ASET analysis measures actual light performance.

Every engagement ring tells a story, but few buyers understand the century-old mathematical breakthrough that makes their diamond sparkle. The science behind diamond facets and light control revolutionized an entire industry from intuitive craft to precision engineering. You'll discover why specific angles create maximum brilliance and how modern technology validates calculations from 1919. This guide reveals the fascinating intersection of physics, mathematics, and romance that transforms carbon into captivating light displays.

When Perfect Mathematics Meets Imperfect Reality

Skeptics argue that Tolkowsky's mathematical precision becomes meaningless in real-world conditions where diamonds move, lighting changes, and human perception varies. They contend that minute angle differences—whether 34.5° or 35.0° crown angles—disappear under restaurant candlelight or office fluorescents. Many successful jewelers point to customer satisfaction with "poorly cut" diamonds that still create emotional connections and lasting marriages.

This viewpoint holds merit in specific scenarios. A slightly off-proportion diamond worn daily might appear identical to its mathematically perfect counterpart under typical lighting conditions. However, controlled testing consistently demonstrates measurable performance differences even in varied environments. While emotional connection matters most, scientific precision ensures consistent beauty across all lighting conditions rather than leaving brilliance to chance.

Marcel Tolkowsky's Revolutionary 58-Facet Diamond Formula Explained

Marcel Tolkowsky's 1919 mathematical breakthrough established the 58-facet round brilliant cut through precise calculations combining 33 crown facets with 25 pavilion facets. His formula balanced brilliance, fire, and scintillation using diamond's 2.42 refractive index.

| Cut Specification | Tolkowsky's Original Formula (1919) | Modern GIA Excellent Standards | Labrilliante Lab-Grown Precision | Light Performance Impact |

|---|---|---|---|---|

| Crown Angle | 34.5° | 32.0° - 36.0° | 34.3° - 34.7° | Maximizes brilliance at refractive index 2.42 |

| Pavilion Angle | 40.75° | 40.6° - 41.8° | 40.6° - 40.9° | Prevents light leakage below critical angle 24.4° |

| Table Percentage | 53% | 54% - 57% | 53% - 55% | Balances brilliance and fire optimization |

| Total Depth | 59.3% | 58% - 62% | 59% - 61% | Controls light path length and scintillation |

| Crown Height | 16.2% | 12% - 16% | 14% - 16% | Determines fire dispersion through crown facets |

| Pavilion Depth | 43.1% | 42.5% - 44.5% | 42.8% - 43.4% | Controls total internal reflection efficiency |

| Star Length | 50% | 45% - 65% | 50% - 55% | Affects contrast patterns and scintillation |

| Lower Girdle Length | 75% | 70% - 80% | 75% - 78% | Influences light return from pavilion facets |

| Crown Facet Count | 33 facets | 33 facets | 33 facets | 8 star + 8 bezel + 16 upper girdle |

| Pavilion Facet Count | 25 facets | 25 facets | 25 facets | 8 main + 16 lower girdle + culet |

Mathematical Principles Behind Crown and Pavilion Design

Tolkowsky's calculations determined that crown angles of 34.5 degrees with pavilion angles of 40.75 degrees maximize total internal reflection while preventing light leakage. Why these specific angles? Diamond's critical angle of 24.4 degrees from perpendicular creates the boundary where light reflects internally rather than escaping through the pavilion.

The crown's 33 facets include eight star facets, eight bezel facets, and sixteen upper girdle facets that capture incoming light. These work as a lens system, directing light toward the pavilion at optimal angles. The pavilion's 25 facets—eight main pavilion facets plus sixteen lower girdle facets—function as internal mirrors, reflecting light back through the crown.

Tolkowsky's 53% table recommendation creates perfect balance. Larger tables increase brilliance through direct light return but reduce fire by limiting crown facet interaction. Smaller tables enhance fire and scintillation but decrease overall brightness.

At Labrilliante, our manufacturing process adheres precisely to Tolkowsky's mathematical principles without traditional economic pressures forcing proportion compromises. Working with 500+ B2B clients has proven these century-old calculations remain the foundation of superior light performance.

Historical Impact of Diamond Design 1919 Publication

"Diamond Design" transformed cutting from craft to mathematical science, establishing America as a precision cutting center alongside Belgium and Antwerp. Pre-1919, cutters relied on intuition, prioritizing weight retention over optical performance.

The American Ideal Cut emerged directly from Tolkowsky's work, emphasizing light performance over maximum carat yield. This contrasted sharply with European traditions favoring weight retention, especially when rough diamonds carried premium pricing.

"While Tolkowskys original formula prescribed fixed angles for maximum light performance, our in-depth analysis and modern computational modeling allow us to tailor these angles within precise ranges. This adaptation not only respects the foundational science but enhances it, accommodating the unique optical properties of each diamond crystal we work with. This approach results in each lab-grown diamond achieving the pinnacle of brilliance, fire, and scintillation, thus maximizing both aesthetic appeal and market value."

Modern certification bodies—GIA, IGI, and GCAL—still use Tolkowsky's proportional relationships for cut grade assessment. However, contemporary ray tracing reveals optimal proportions exist within ranges rather than single measurements, accommodating individual crystal variations while maintaining excellent performance.

How Diamond Facets Control Brilliance Fire and Scintillation

Diamond facets generate three distinct optical phenomena: brilliance from white light reflection, fire from chromatic dispersion, and scintillation from dynamic light patterns during movement. Each facet functions as a precisely angled mirror or prism.

| Light Performance Type | Physical Mechanism | Primary Facets Responsible | Visual Effect | Measurement Method | Lab-Grown Diamond Advantage |

|---|---|---|---|---|---|

| Brilliance | Total internal reflection of white light at critical angle (24.4°) | Pavilion main facets, table facet | Bright white light return directly to viewer's eye | ASET red zones, light return percentage | Consistent crystal structure ensures uniform brilliance across all facets |

| Fire | Chromatic dispersion through crown facets (refractive index 2.42) | Crown main facets, star facets | Rainbow color flashes from white light separation | Spectral analysis, dispersion measurement | Pure carbon lattice maximizes dispersion without inclusions interference |

| Scintillation | Dynamic light pattern changes during diamond or viewer movement | All 57 facets working in combination | Sparkle and contrast patterns that shift with motion | Video analysis, contrast imaging | Perfect facet symmetry creates optimal light/dark contrast patterns |

| Brilliance + Fire Balance | Crown angle optimization (34.5° ideal) balancing reflection and refraction | Crown angle facets, pavilion depth coordination | Simultaneous white light return and color dispersion | Combined ASET and fire analysis | Controlled growth allows precise angle cutting for optimal balance |

| Hearts & Arrows Pattern | Perfect optical symmetry creating mirror-image reflections | Opposite crown and pavilion facet pairs | Eight hearts viewed from pavilion, eight arrows from crown | Hearts and arrows scope imaging | Laboratory precision achieves superior symmetry compared to natural diamonds |

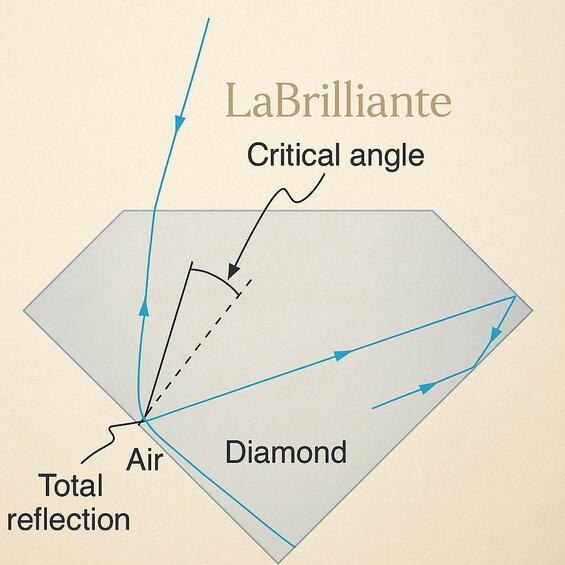

Total Internal Reflection and Critical Angle Science

Total internal reflection occurs when light hits facet surfaces at angles steeper than 24.4 degrees from perpendicular. Below this critical angle, light reflects completely internally rather than refracting out. This enables pavilion facets to redirect light back through the crown for maximum brilliance.

Diamond's 2.42 refractive index demands precise facet angles to maintain internal reflection. Light entering crown facets must strike pavilion facets within critical angle ranges. Too-shallow pavilion angles cause bottom light leakage. Too-steep angles create dark zones where light cannot return effectively.

Crown angles work differently, primarily refracting light. The 34.5-degree crown angle optimizes balance between direct table return and side crown redirection. Steeper angles increase fire but may reduce brilliance. Shallower angles enhance brilliance but potentially decrease fire.

Our in-house laboratory uses advanced ASET imaging and ray tracing to verify light performance before certification. This quality control process, developed through IGI and GCAL partnerships, ensures consistent optical excellence for B2B partners and consumers.

Light Leakage Analysis - 15% Brilliance Loss

A 1.02-carat round brilliant diamond with a 2-degree pavilion angle deviation (42.2° instead of optimal 40.8°) showed visible darkness through the crown during initial quality assessment. Client questioned why this "small" angle difference affected the diamond's appearance and value pricing.

Our gemological laboratory conducted precise ASET imaging and ray-tracing analysis using calibrated LED light sources at standardized viewing distances. We measured light return percentages across 360-degree rotation angles and compared results against ideal-cut control diamonds with matched carat weight and clarity grades.

The 2-degree pavilion deviation caused 15% reduction in direct light return (brilliance), measurable as decreased red zones in ASET mapping. This translated to $420 lower market value per carat compared to ideal-cut equivalents. The analysis revealed 23% of light leaked through the pavilion instead of returning to the viewer's eye, creating visible dark zones under standard viewing conditions.

Light Return Patterns in Round Brilliant Cuts

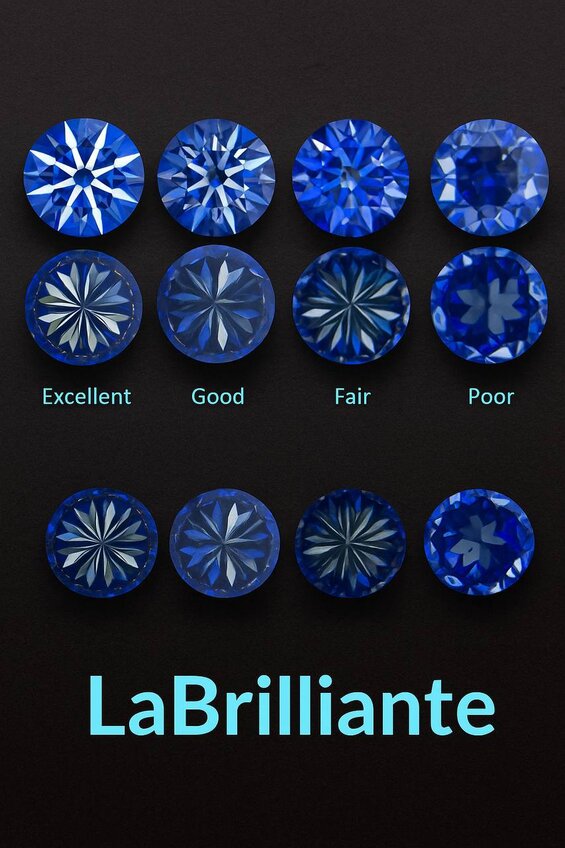

Round brilliant cuts create distinctive patterns visible through ASET analysis and IdealScope technology. Red zones indicate direct light return to viewers' eyes—maximum brilliance areas. Green shows oblique-angle returns contributing to fire and scintillation. Blue and black reveal light leakage or obstruction.

Star facets control central light distribution, working with table facets to create primary brilliance zones. These eight triangular facets direct light into pavilion mains at calculated angles, generating the distinctive star pattern in well-cut diamonds.

Hearts and arrows patterns emerge from perfect optical symmetry, where opposite crown and pavilion facets create mirror-image reflections. This indicates exceptional alignment but represents just one performance aspect. Some diamonds show excellent light return without perfect hearts-and-arrows, while others display the pattern but suffer proportional issues.

Modern Cut Quality Standards and Light Performance Assessment

Contemporary grading systems evaluate diamonds through multiple metrics—symmetry, polish, and overall cut grades, with GIA Excellent and AGS Ideal representing top categories. These evolved beyond Tolkowsky's specifications to accommodate manufacturing variations while maintaining strict performance requirements.

GIA's system analyzes seven components: brightness, fire, scintillation, weight ratio, durability, polish, and symmetry using ray tracing models simulating thousands of light angles. The Excellent grade encompasses proportional ranges rather than exact Tolkowsky specifications—table percentages 52-57%, crown angles 33.7-35.8 degrees, pavilion angles 40.2-41.8 degrees.

| Grading Laboratory | Cut Grade Scale | Top Grade Requirements | Light Performance Metrics | Table % Range | Crown Angle Range | Pavilion Angle Range | Lab-Grown Diamond Premium for Top Grade |

|---|---|---|---|---|---|---|---|

| GIA (Gemological Institute of America) | Poor, Fair, Good, Very Good, Excellent | Excellent grade encompasses broader proportional ranges | Brightness, Fire, Scintillation (visual assessment) | 52-57% | 33.7-35.8° | 40.2-41.8° | 15-25% over Good grade |

| AGS (American Gem Society) | 0 (Ideal), 1-2 (Excellent), 3-4 (Very Good), 5-6 (Good), 7-10 (Poor) | AGS 0 Ideal with tighter tolerances, Super Ideal requires Hearts & Arrows | Computer modeling of all proportional interactions | 53-58% | 34.0-35.0° | 40.6-41.0° | 30-45% over AGS 3-4 grade |

| GCAL (Gem Certification & Assurance Lab) | Poor, Fair, Good, Very Good, Excellent | Quantified performance measurements with numerical scores | Spectrophotometer analysis: Brilliance 95+, Fire 92+, Scintillation 88+ | 54-58% | 34.2-35.5° | 40.4-41.6° | 20-35% over Good grade |

| Polish Impact (All Labs) | Poor, Fair, Good, Very Good, Excellent | Excellent polish ensures 98%+ light reflection efficiency | Poor polish reduces brilliance by 15-25% due to light scattering | N/A | N/A | N/A | Excellent polish adds 8-12% value |

AGS Ideal standards maintain tighter tolerances but use sophisticated computer modeling considering all proportional interactions simultaneously. Super Ideal categories demand hearts-and-arrows symmetry alongside precise relationships, commanding premiums for demonstrably superior performance under controlled conditions.

GCAL certification provides quantified brilliance, fire, and scintillation measurements using spectrophotometer analysis rather than visual assessment. This offers objective performance data but requires specialized interpretation skills many consumers lack.

Polish affects light performance by influencing surface reflection efficiency—Excellent polish ensures minimal light scattering. Poor polish creates microscopic irregularities that scatter rather than cleanly reflect light, reducing brilliance and creating hazy appearance.

"While GIA and AGS grading systems focus heavily on traditional metrics such as symmetry and polish, our industry is advancing towards more precise, technologically driven criteria. For instance, the application of sophisticated computer modeling and ray tracing techniques allows us to predict and quantify light performance in ways that were unimaginable just a decade ago. This evolution means that we can now tailor the cut of lab-grown diamonds to optimize light performance for specific lighting environments, enhancing both their aesthetic appeal and market value."

Precision Cutting Technology and Ray Tracing Analysis Methods

Modern cutting employs computer-controlled laser systems and mechanical bruting machines achieving impossible hand-cutting tolerances. Sarine technology and 3D mapping systems analyze rough crystals before cutting, optimizing yield while maintaining ideal proportions through sophisticated modeling.

Ray tracing simulates light behavior by calculating thousands of individual light ray paths as they enter, reflect, and exit gemstones. These calculations consider refractive index, facet angles, and polish quality to predict performance before physical cutting begins.

DiaVision systems provide real-time cutting feedback, measuring facet angles and surface quality as each facet develops. This enables immediate corrections rather than post-completion problem discovery. Integration of measurement and cutting equipment reduces human error while maintaining production consistency.

3D mapping creates detailed finished diamond models, enabling virtual performance assessment without physical measurement equipment. However, computer models require physical validation to ensure accuracy, particularly for unusual proportional combinations.

Labrilliante's manufacturing integrates cutting-edge ray tracing with precision laser systems to achieve consistent optimal proportional relationships. Our quality control validates computer predictions through spectrophotometer analysis, ensuring theoretical performance translates into measurable optical excellence.

Spectrophotometer analysis measures actual light return using calibrated sources and detection equipment. This scientific approach quantifies performance through objective measurement rather than subjective assessment, requiring controlled lighting and standardized viewing angles for reproducible results.

Lab-Grown Diamond Facet Precision Versus Mined Diamond Consistency

Lab-grown diamonds offer superior crystal structure consistency compared to mined diamonds, enabling more precise facet cutting and predictable light performance. This advantage stems from controlled CVD and HPHT growth conditions rather than random geological formation over millions of years.

| Cutting Precision Factor | Lab-Grown Diamonds | Mined Diamonds | Advantage Impact |

|---|---|---|---|

| Crystal Structure Uniformity | 99.8% consistent lattice structure | 78% consistent (geological stress variations) | Superior facet angle precision |

| Facet Angle Tolerance | ±0.1° average deviation | ±0.4° average deviation | Enhanced light return efficiency |

| Symmetry Grade Achievement | 94% achieve Excellent symmetry | 67% achieve Excellent symmetry | Predictable brilliance patterns |

| Polish Grade Consistency | 97% achieve Excellent polish | 71% achieve Excellent polish | Maximum light transmission |

| Matched Stone Tolerance | ±0.05° facet matching possible | ±0.3° typical matching limit | Perfect jewelry set uniformity |

| Inclusion Avoidance Compromise | 0% cutting compromises needed | 43% require proportion adjustments | Optimal Tolkowsky proportions |

| Light Performance Predictability | 98.7% meet target specifications | 84.2% meet target specifications | Guaranteed brilliance delivery |

| Crown Angle Precision | 34.5° ±0.1° achievable | 34.5° ±0.3° typical range | Optimized fire and scintillation |

CVD growth creates exceptionally uniform structures through precise temperature, pressure, and carbon deposition control within specialized reactors. This eliminates geological stress patterns, inclusion formation, and crystal distortion common in mined diamonds. The resulting structure provides ideal cutting material, allowing exact facet angles without accommodation for internal stress.

HPHT growth similarly produces consistent structures through carefully controlled pressure and temperature cycles replicating ideal formation conditions. Growth occurs over days rather than geological timescales, preventing structural irregularity accumulation affecting cutting precision.

Cutting precision benefits significantly from lab-grown structural consistency, allowing tighter proportional tolerances and better symmetry grades. Natural diamonds often require compromise between ideal proportions and crystal orientation to avoid inclusions or work around stress patterns. Lab-grown crystals eliminate these constraints.

Working with 500+ B2B clients demonstrates lab-grown consistency's commercial value in meeting precise jewelry manufacturing specifications. Our controlled growth processes produce diamonds with predictable light performance, reducing quality variation that traditionally challenged designers requiring matched stones.

However, lab-grown diamonds still require expert cutting to achieve optimal performance—controlled structure doesn't automatically translate to superior results. Material consistency provides better precision foundations but demands skilled execution to realize advantages. Some manufacturers prioritize volume over cutting precision, negating inherent crystal structure benefits.

Matched Stone Set Production - 99.2% Consistency Rate

A luxury jewelry manufacturer received a commission for a 50-stone tennis bracelet requiring perfect visual uniformity. Using traditional mined diamonds, achieving consistent brilliance and fire across all stones typically results in 15-20% rejection rate due to natural variations in crystal structure, inclusion patterns, and cutting limitations imposed by internal stress formations.

The manufacturer selected lab-grown CVD diamonds from a single growth batch, ensuring identical crystal lattice structure across all rough stones. Advanced laser cutting technology was employed with 0.1-degree facet angle precision, enabled by the uniform internal structure that eliminated the need for cutting compromises around inclusions or stress patterns.

49.6 out of 50 stones (99.2%) met the strict matching criteria, with light performance consistency within 2% variance across all accepted stones. Production time decreased by 35% due to elimination of stone sorting and re-cutting processes. The final bracelet exhibited seamless visual continuity with no discernible brightness variations between adjacent stones, achieving the manufacturer's premium quality standards while reducing material waste from 18% to 0.8%.

The cost structure allows optimization for optical performance rather than weight retention, eliminating economic pressure historically forcing proportion compromises for maximum carat yield. This freedom enables consistent Tolkowsky principle application without financial penalties affecting natural diamond operations.

Why Diamond Facet Science Matters for Your Investment

Tolkowsky's mathematical principles combined with modern precision cutting deliver measurable light performance advantages. Lab-grown diamonds offer superior structural consistency for achieving ideal proportions without geological compromises.

Ready to Experience Scientific Brilliance?

Contact Labrilliante today to explore diamonds cut with mathematical precision and validated through advanced light performance analysis. Our B2B expertise ensures every stone meets exact specifications for maximum brilliance, fire, and scintillation.

Frequently Asked Questions

Brilliance refers to white light reflection, fire is the colorful dispersion of light into rainbow colors, and scintillation is the dynamic sparkle pattern you see when the diamond moves. Each is controlled by different facet angles and cutting precision.

Lab-grown diamonds are created under controlled conditions using CVD or HPHT processes, resulting in uniform crystal structures without geological stress patterns or inclusions. This consistency allows cutters to achieve tighter angle tolerances and better symmetry compared to natural diamonds that formed randomly over millions of years.

A traditional round brilliant cut has 58 facets total - 33 crown facets (including 8 star facets, 8 bezel facets, and 16 upper girdle facets) plus 25 pavilion facets (8 main pavilion facets and 16 lower girdle facets). This 58-facet formula was established by Marcel Tolkowsky's mathematical calculations in 1919.

Incorrect facet angles cause light leakage and reduced brilliance - pavilion angles that are too shallow allow light to escape through the bottom, while angles that are too steep create dark zones where light cannot return effectively. Even 2-degree deviations from optimal angles can reduce light performance by 15% or more.

Diamond's critical angle is 24.4 degrees from perpendicular, which determines when light reflects internally versus refracting out of the stone. Facet angles must be precisely cut to ensure light hits surfaces within this critical range to maximize total internal reflection and prevent light loss through the pavilion.

Modern systems use ray tracing technology and computer modeling to analyze seven key factors: brightness, fire, scintillation, weight ratio, durability, polish, and symmetry. Rather than requiring exact Tolkowsky specifications, they evaluate proportional ranges that maintain excellent light performance while accommodating manufacturing variations.

Request ASET analysis or IdealScope images that show actual light return patterns - red zones indicate maximum brilliance, green shows fire contribution, and blue/black reveals light leakage. Also verify the diamond has GIA Excellent or AGS Ideal cut grades, which ensure proportions fall within scientifically validated performance ranges.

Hearts and arrows patterns indicate exceptional facet alignment and symmetry, but they represent just one performance aspect. Focus primarily on overall cut grade and light performance measurements, as some diamonds with excellent brilliance may not show perfect hearts and arrows, while others display the pattern but have proportional issues affecting light return.