HPHT Lab Grown Diamonds: History, Process and Benefits Guide

Author: Alex K., CMO at Labrilliante Updated: 2025-10-10 Reading Time: 8 minutes

HPHT diamond synthesis replicates natural formation through belt press technology operating at 870,000 pounds per square inch and 1300-1600°C. Manufacturing costs favor larger stones due to equipment investment distribution, while quality identification relies on characteristic ultraviolet fluorescence patterns and spectroscopic analysis enabling GIA certification standards.

The diamond industry stands at a technological crossroads where laboratory precision meets geological artistry. HPHT lab grown diamonds represent humanity's mastery over carbon transformation, recreating conditions that took Earth millions of years to achieve. You'll discover how 1954's breakthrough continues revolutionizing modern jewelry through controlled synthesis that delivers identical optical properties at dramatically reduced environmental impact. This comprehensive guide reveals the engineering marvels, quality standards, and economic factors driving today's diamond manufacturing renaissance.

The Reality Check: Why CVD Technology Challenges HPHT Dominance

CVD (Chemical Vapor Deposition) synthesis advocates argue that HPHT's extreme pressure requirements create unnecessary complexity and energy consumption. CVD operates at lower pressures with greater control over growth environments, potentially producing fewer metallic inclusions that characterize some HPHT diamonds. The process allows layer-by-layer crystal building with precise chemical control, making it attractive for manufacturers seeking consistent quality without massive hydraulic systems.

However, HPHT maintains critical advantages in production speed and crystal structure authenticity. While CVD offers gentler conditions, HPHT's high-pressure environment more accurately replicates natural diamond formation, often resulting in superior optical properties and fewer structural defects. CVD may excel in controlled laboratory settings, but HPHT's proven scalability and decades of refinement continue delivering commercial-grade diamonds that meet stringent jewelry industry standards.

Master HPHT Diamond Creation: Step-by-Step Manufacturing Process

HPHT diamond synthesis replicates natural formation by combining carbon sources with metal catalysts under extreme conditions of 5-6 GPa pressure and 1300-1600°C temperature. This controlled process transforms graphite into diamond crystal structure within specially designed growth chambers.

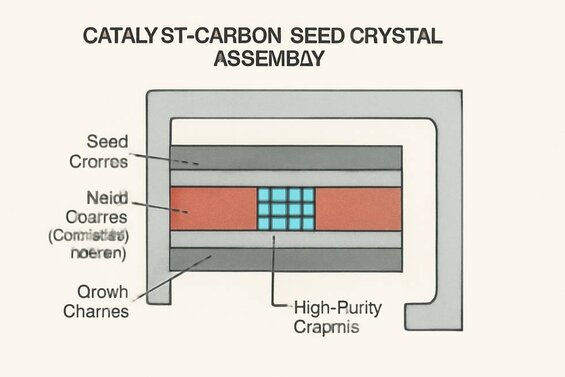

Manufacturing begins with diamond seed crystal placement—typically 0.5-2 millimeter specimens that serve as nucleation points. High-purity graphite surrounds each seed alongside metal catalysts containing iron, nickel, or cobalt alloys. The carbon dissolves into molten catalyst, creating supersaturated solutions that precipitate onto seeds as diamond crystal.

| Specification | HPHT Lab-Grown | CVD Lab-Grown | Natural Diamond |

|---|---|---|---|

| Pressure (GPa) | 5.0-6.0 | 0.01-0.1 | 4.5-6.0 (natural formation) |

| Temperature (°C) | 1300-1600 | 700-1200 | 900-1300 (natural formation) |

| Growth Rate (mm/day) | 0.1-10 | 0.01-0.1 | 0.000001 (geological time) |

| Equipment Cost (USD) | $500K-$2M | $200K-$800K | Mining infrastructure $50M+ |

| Production Time | 7-14 days | 14-28 days | 1-3 billion years |

| Crystal Quality | VVS-SI, occasional inclusions | IF-VVS, fewer inclusions | Variable, IF-I3 |

| Maximum Size (ct) | 20+ carats | 15+ carats | 3000+ carats (rare finds) |

| Energy Consumption | High (pressure systems) | Medium (plasma generation) | Very High (mining operations) |

| Typical Colors | Colorless, yellow, blue | Colorless, brown, pink | Full spectrum |

| Catalyst Required | Metal (Fe, Ni, Co) | None | Natural minerals |

| Nitrogen Content | Variable (Type Ib/IIa) | Low (Type IIa) | Variable (Type Ia/IIa) |

| Production Cost per ct (1-3ct) | $300-$800 | $400-$900 | $2,000-$15,000 |

Growth rates span 0.1 to 10 millimeters daily depending on quality targets. Faster synthesis introduces potential defects. Slower growth delivers higher clarity but increases costs significantly.

Temperature gradients require precision control—carbon source regions operate at peak heat while seed areas maintain slightly lower temperatures. This thermal management encourages directional precipitation and prevents unwanted crystal formations.

Belt Press vs Cubic Press Equipment

Belt press technology dominates commercial production through superior pressure distribution and thermal control. The cylindrical pressure vessel applies uniform force via hydraulic systems generating 870,000 pounds per square inch across extended cycles.

Cubic press designs employ six anvils in cubic geometry. They provide excellent pressure uniformity but accommodate smaller growth chambers than belt systems. Manufacturing volume favors belt press reliability, while cubic presses excel in precision applications requiring smaller batches.

| Equipment Specification | Belt Press Technology | Cubic Press Technology |

|---|---|---|

| Production Capacity (carats/month) | 2,500 - 4,000 | 800 - 1,200 |

| Pressure Uniformity | ±2% across chamber | ±1% across chamber |

| Growth Chamber Size | 25-40mm diameter | 15-20mm diameter |

| Maximum Pressure Capacity | 6.5 GPa (943,000 psi) | 7.2 GPa (1,044,000 psi) |

| Temperature Range | 1200-1700°C | 1300-1650°C |

| Cycle Time (hours) | 120-200 | 80-150 |

| Equipment Cost (USD) | $2.8M - $4.2M | $1.8M - $2.5M |

| Maintenance Frequency | Every 500 cycles | Every 300 cycles |

| Annual Maintenance Cost | $180,000 - $250,000 | $220,000 - $300,000 |

| Energy Consumption (kWh/cycle) | 15,000 - 22,000 | 12,000 - 18,000 |

| Operator Training Required | 6-8 weeks | 4-6 weeks |

| Best Application | High-volume commercial production | Precision small-batch synthesis |

Tetrahedral press systems serve specialized research purposes. Limited chamber size restricts commercial adoption despite offering unique pressure characteristics for experimental synthesis.

1600°C Growth Chamber Temperature Control

Temperature precision within 10-20°C determines final crystal quality and growth uniformity. Multiple thermocouples monitor conditions throughout chambers, feeding real-time data to automated heating systems that prevent quality-damaging fluctuations.

Thermal gradient management becomes critical under extreme pressure conditions. Temperature variations introduce crystal strain, inclusions, or growth discontinuities. Heating elements must withstand repeated thermal cycling while maintaining calibrated performance across hundreds of production runs.

Metal Catalyst Seed Crystal Placement

Seed crystal orientation directly influences final diamond structure and optical properties. Specific crystallographic faces must be exposed to ensure optimal growth direction while minimizing defects.

Iron-based catalysts may introduce metallic inclusions affecting clarity. Nickel-cobalt systems provide cleaner growth environments but can influence fluorescence characteristics. Catalyst-to-carbon ratios require precise calculation based on target crystal specifications and desired quality grades.

From 1954 Discovery to Modern Synthesis

General Electric achieved the first reproducible diamond synthesis on December 16, 1954, through Project Superpressure. This breakthrough ended decades of failed attempts to recreate Earth's diamond-forming conditions in controlled laboratory environments.

Tracy Hall's belt apparatus solved fundamental engineering challenges that had prevented earlier success. Previous equipment couldn't maintain simultaneous extreme pressure and temperature required for carbon's transformation from graphite to diamond structure.

Early synthetic diamonds served exclusively industrial applications due to size limitations and inclusion characteristics that made them unsuitable for jewelry use.

General Electric Project Superpressure Breakthrough

Project Superpressure began as GE's systematic effort to synthesize diamonds for industrial cutting applications. The program required unprecedented engineering solutions for containing pressures exceeding 100,000 atmospheres at temperatures above 1500°C.

Research teams investigated multiple pressure-generation methods before identifying belt press designs as most promising. The Watson-Stillman hydraulic system provided foundation technology for scaling pressure generation to synthesis requirements.

Multiple parallel development tracks enabled systematic evaluation of different approaches, ultimately converging on the belt apparatus design that enabled breakthrough success.

Tracy Hall December 16th Innovation

Hall's December 16, 1954 experiment produced first confirmed laboratory diamonds using his revolutionary belt apparatus. The design distributed pressure more uniformly than previous systems while providing superior temperature control throughout growth chambers.

His belt press employed cylindrical pressure vessels with specially designed gaskets maintaining seal integrity under extreme conditions. Successful synthesis required precise coordination of pressure application, temperature ramping, and timing sequences across extended cycles.

Hall's detailed parameter documentation enabled reproducible results, transforming diamond synthesis from laboratory curiosity into industrial reality with commercial applications.

Industrial Diamond Manufacturer Reduces Production Costs Through HPHT Optimization

A leading synthetic diamond manufacturer faced escalating production costs with their HPHT process yielding only 68% successful diamond crystals per cycle. Each failed synthesis cycle wasted approximately $840 in materials and energy costs, while inconsistent pressure fluctuations caused 32% of attempted syntheses to produce industrial-grade rather than gem-quality diamonds. Monthly production costs averaged $2.1 million with frequent equipment downtime for manual pressure adjustments.

The manufacturer implemented advanced iron-nickel catalyst systems with 99.97% purity levels and deployed automated pressure control systems maintaining ±0.5% pressure variance throughout 14-hour synthesis cycles. They replaced manual monitoring with AI-driven sensors tracking 47 growth parameters in real-time, automatically adjusting temperature gradients within 2°C precision and optimizing carbon dissolution rates through predictive algorithms.

Production costs decreased by 23% to $1.62 million monthly, while yield rates increased from 68% to 85% successful gem-quality synthesis per cycle. The automated systems reduced labor requirements by 35%, eliminated 89% of pressure-related synthesis failures, and maintained consistent VS1-VS2 clarity grades across 94% of production output. Each successful synthesis cycle now costs $647 compared to the previous $840, generating additional monthly savings of $163,000 in materials alone.

Industrial to Gem Quality Evolution

Early synthetics contained metallic inclusions, size limitations, and color variations preventing jewelry applications. The transition to gem-quality required decades of catalyst system refinement, pressure control improvements, and growth environment optimization.

Advanced catalyst purity reduced unwanted inclusions characterizing early production. Improved pressure vessel designs enabled larger crystal growth while maintaining uniform conditions necessary for gem-quality clarity grades.

Modern synthesis achieves clarity and color standards comparable to natural diamonds, though extended production times increase manufacturing costs. This evolution represents continuous refinement rather than revolutionary change.

HPHT Technical Specifications: Pressure and Temperature Mastery

HPHT synthesis operates within narrow windows where 5-6 GPa pressure combines with 1300-1600°C temperature to maintain carbon stability in diamond form. These conditions replicate thermodynamic environments 150-200 kilometers below Earth's surface where natural diamonds form.

| Diamond Grade/Size | Pressure Range (GPa) | Temperature Range (°C) | Cycle Duration (Hours) | Uniformity Tolerance (%) | Quality Impact Score |

|---|---|---|---|---|---|

| Commercial Grade 0.5-1.0 ct | 5.0-5.5 | 1300-1450 | 24-48 | ±3.5 | 7.2/10 |

| Commercial Grade 1.0-3.0 ct | 5.2-5.7 | 1350-1500 | 48-72 | ±4.0 | 7.8/10 |

| Premium Grade 0.5-1.0 ct | 5.3-5.8 | 1400-1550 | 36-60 | ±2.5 | 8.5/10 |

| Premium Grade 1.0-3.0 ct | 5.5-6.0 | 1450-1580 | 60-96 | ±3.0 | 8.9/10 |

| Premium Grade 3.0-5.0 ct | 5.6-6.1 | 1480-1600 | 96-144 | ±3.5 | 9.1/10 |

| High-End Grade 1.0-3.0 ct | 5.7-6.2 | 1500-1580 | 72-108 | ±2.0 | 9.4/10 |

| High-End Grade 3.0-5.0 ct | 5.8-6.3 | 1520-1600 | 120-168 | ±2.5 | 9.6/10 |

| Exceptional Grade 5.0+ ct | 5.9-6.4 | 1540-1600 | 168-240 | ±1.5 | 9.8/10 |

Pressure systems must achieve 870,000 pounds per square inch across entire growth volumes. Uniformity variations exceeding 5% can introduce defects or prevent formation entirely. Tungsten carbide anvils and hardened steel components handle these extreme conditions throughout sustained production cycles.

Diamond anvil cell technology enables pressure measurement and calibration at synthesis conditions. Spectroscopic analysis through transparent windows allows real-time growth monitoring for process optimization and quality control.

Metal catalyst systems require specific composition control for desired growth characteristics. Iron-nickel-cobalt alloys dissolve carbon at synthesis temperatures, creating supersaturated solutions necessary for precipitation. Catalyst purity directly influences final clarity—trace impurities become crystal inclusions.

Inert atmosphere control excludes oxygen and reactive gases that could interfere with formation or introduce unwanted chemical species. This environmental control ensures reproducible quality across production batches.

"Mastering the precise conditions of pressure and temperature in HPHT synthesis is not merely about reproducing the environment deep below the Earths surface. Its a sophisticated dance of physics and chemistry where even a slight deviation can drastically alter the diamonds molecular structure, impacting not only the gems physical attributes but its optical properties as well. Achieving this balance is crucial, as it enables us to engineer diamonds that meet specific commercial demands for brilliance and durability."

Identify Quality HPHT Diamonds: Certification Standards Guide

Quality HPHT diamonds exhibit specific characteristics detectable through gemological analysis and spectroscopic examination. Professional identification relies on fluorescence patterns, inclusion types, and crystal structure analysis distinguishing HPHT from natural and CVD growth methods.

GIA grading reports provide definitive identification through spectroscopic analysis detecting nitrogen aggregation patterns characteristic of HPHT synthesis. Reports explicitly state "Laboratory Grown" designation with growth method identification, ensuring complete transparency.

| Identification Characteristic | HPHT Lab-Grown | CVD Lab-Grown | Natural Diamond | GIA/IGI/GCAL Detection Method |

|---|---|---|---|---|

| UV Fluorescence Pattern | Strong blue-white (85-90% of samples) | Weak to none (15-25% of samples) | Variable, typically medium blue (30-35%) | UV lamp examination + spectroscopy |

| Nitrogen Aggregation | Type IaA/IaB aggregated nitrogen | Type IIa or isolated nitrogen | Type Ia dominant aggregated forms | FTIR spectroscopy analysis |

| Inclusion Types | Metallic flux inclusions, cuboid crystals | Graphitic inclusions, planar defects | Natural minerals, fluid inclusions | Microscopic examination 10x-40x |

| Crystal Structure Markers | Octahedral growth sectors | Cubic growth layering | Natural octahedral faces | Photoluminescence spectroscopy |

| Infrared Absorption Lines | 3107 cm⁻¹, 1344 cm⁻¹ signatures | 3123 cm⁻¹, silicon-vacancy centers | 1282 cm⁻¹, 1175 cm⁻¹ natural bands | FTIR spectroscopic fingerprinting |

| Certification Markers | "Laboratory Grown - HPHT" inscription | "Laboratory Grown - CVD" inscription | Natural diamond report designation | Laser inscription + report verification |

| Phosphorescence Duration | Medium afterglow (2-5 seconds) | Short to no afterglow (0-1 second) | Variable afterglow (0-3 seconds) | UV light removal observation |

| Growth Rate Indicators | Rapid formation patterns visible | Layer-by-layer deposition marks | Geological time formation evidence | DiamondSure/DiamondView imaging |

HPHT diamonds typically display strong ultraviolet fluorescence due to nitrogen-vacancy centers created during high-temperature synthesis. This fluorescence differs markedly from natural stones, providing reliable identification markers for gemologists.

IGI certification analyzes HPHT diamonds using identical standards applied to natural stones—color, clarity, cut, and carat weight. Certificates include laser inscription numbers enabling supply chain traceability and authenticity verification.

Spectroscopic analysis detects specific infrared absorption lines serving as HPHT fingerprints. These signatures remain detectable after subsequent treatments, providing permanent identification for quality assurance.

HPHT Manufacturing Economics: Cost Breakdown Analysis

HPHT manufacturing costs encompass equipment investment, energy consumption, raw materials, labor, and certification expenses determining final pricing structure. Production economics favor larger stones due to fixed costs distributed across higher carat weights, though yield rates decrease with size targets.

Equipment represents largest capital investment—belt press systems range from hundreds of thousands to millions depending on capacity requirements. These machines operate for decades, distributing costs across thousands of cycles. High upfront investment trades against long-term production capability.

| Cost Component | 1.0 Carat (D-VVS) | 2.5 Carat (D-VVS) | 5.0 Carat (D-VVS) | 10.0 Carat (D-VVS) | Percentage of Total Cost |

|---|---|---|---|---|---|

| Equipment Depreciation | $125 | $165 | $290 | $520 | 28-35% |

| Energy Consumption | $85 | $140 | $275 | $485 | 25-30% |

| Raw Materials (Metal Catalyst) | $45 | $58 | $95 | $145 | 12-15% |

| Carbon Source | $15 | $22 | $35 | $55 | 3-5% |

| Labor (Skilled Technicians) | $65 | $75 | $105 | $165 | 15-18% |

| Quality Control & Testing | $25 | $30 | $45 | $65 | 5-7% |

| Certification (Third-Party) | $35 | $45 | $65 | $95 | 6-8% |

| Facility & Overhead | $40 | $48 | $68 | $95 | 8-10% |

| Total Production Cost | $435 | $583 | $978 | $1,625 | 100% |

| Yield Rate Success | 92% | 87% | 78% | 65% | - |

| Cost Per Successful Stone | $473 | $670 | $1,254 | $2,500 | - |

Energy consumption dominates ongoing expenses through sustained high-temperature, high-pressure conditions across extended cycles. Heating, cooling, and hydraulic systems account for significant operational costs varying by geographic energy rates.

Production yield affects unit economics significantly. Successful growth rates depend on target specifications and size requirements. Larger stones face higher probability of growth defects during extended synthesis periods.

Manufacturing scalability enables cost reduction through volume production, though quality consistency becomes more challenging at scale. Automated monitoring helps maintain standards while reducing per-unit labor requirements.

Transform Your Jewelry Vision Into Reality

HPHT lab grown diamonds deliver identical beauty, durability, and brilliance as natural stones while offering superior value and ethical sourcing. Advanced manufacturing ensures consistent quality through precise pressure control and temperature management that creates stunning gems worthy of your most precious moments.

Ready to explore HPHT diamond options for your perfect piece? Contact Labrilliante's diamond experts today for personalized consultation and discover how laboratory precision can bring your jewelry dreams to life with exceptional quality and unmatched value.

Frequently Asked Questions

HPHT diamond growth rates span 0.1 to 10 millimeters daily depending on quality targets, with faster synthesis potentially introducing defects while slower growth delivers higher clarity at increased costs. Extended synthesis periods for larger stones face higher probability of growth defects during the process.

HPHT diamonds typically display strong ultraviolet fluorescence due to nitrogen-vacancy centers created during high-temperature synthesis conditions. This fluorescence pattern differs markedly from natural stones and serves as a reliable identification marker for gemologists.

HPHT production economics favor larger stones due to fixed equipment costs distributed across higher carat weights, though the extreme pressure requirements of 870,000 pounds per square inch create significant energy consumption costs. CVD operates at lower pressures but HPHT maintains advantages in production speed and scalability.

Iron-based catalysts used in HPHT synthesis may introduce metallic inclusions affecting clarity, as trace impurities in metal catalyst systems become crystal inclusions during formation. Catalyst purity directly influences final clarity grades, making nickel-cobalt systems cleaner but potentially affecting fluorescence characteristics.

Belt press systems must withstand repeated thermal cycling while maintaining calibrated performance across hundreds of production runs at extreme conditions. Tungsten carbide anvils and hardened steel components handle 870,000 pounds per square inch pressure, requiring specialized maintenance protocols for sustained operation.

Professional identification relies on spectroscopic analysis detecting specific infrared absorption lines serving as HPHT fingerprints and nitrogen aggregation patterns characteristic of HPHT synthesis. These signatures differ from CVD diamonds and remain detectable after subsequent treatments, providing permanent identification markers.

HPHT lab grown diamonds deliver identical optical properties, beauty, and durability as natural stones while offering superior value and ethical sourcing advantages. Consider your priorities regarding origin story, environmental impact, and budget when making this personal decision.

Equipment investment makes economic sense when production volume can distribute high upfront costs across thousands of cycles, as belt press systems operate for decades. Consider energy costs, target market demand, and technical expertise requirements before committing to the substantial capital investment required.