How to Differentiate HPHT and CVD Lab-Grown Diamonds

Author: Alex K., CMO at Labrilliante Updated: 2025-01-10 Reading Time: 8 minutes

Professional gemologists use photoluminescence spectroscopy and DiamondView imaging to distinguish HPHT from CVD lab-grown diamonds. HPHT shows cuboctahedral crystal structures with geometric sectors, while CVD displays parallel striations from layer-by-layer growth. IGI and GIA certifications explicitly state growth methods through advanced testing protocols.

Lab-grown diamonds have revolutionized the jewelry industry, but understanding their origins matters more than ever. Two dominant manufacturing methods—HPHT and CVD—create diamonds with subtle yet distinctive characteristics that affect everything from certification to market value. Mastering these identification techniques empowers jewelers, collectors, and consumers to make informed decisions based on scientific manufacturing differences. We'll explore the visual signatures, professional testing methods, and quality implications that separate these revolutionary diamond creation processes.

When Visual Identification Falls Short: The Certification Dependency Reality

Many gemological professionals argue that visual identification methods for HPHT and CVD diamonds are unreliable without expensive laboratory equipment. Basic jewelers lack access to photoluminescence spectroscopy, DiamondView imaging, or advanced magnification systems required for definitive distinction. Small retail operations can't justify $50,000+ equipment investments for occasional identification needs.

This criticism holds weight in everyday retail scenarios. Visual characteristics like crystal structures and growth patterns require specialized training and optimal viewing conditions. Subtle differences become nearly impossible to detect in mounted stones or under standard jewelry store lighting. However, this limitation actually reinforces the importance of proper certification from IGI, GIA, or GCAL laboratories. Professional grading reports provide definitive growth method identification backed by advanced testing protocols. While visual techniques offer valuable educational insights, certified documentation remains the reliable standard for consumer protection and market transparency.

Master Visual Diamond Growth Method Identification Techniques

HPHT diamonds show cuboctahedral crystal structures with geometric patterns, while CVD diamonds display layered formations with parallel striations. These visual signatures reveal each method's distinct manufacturing process.

| Characteristic | HPHT (High Pressure High Temperature) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Growth Pressure | 5+ gigapascals (50,000+ atmospheres) | 0.1-0.3 atmospheres (near vacuum) |

| Growth Temperature | 1,400-1,600°C | 700-1,000°C |

| Crystal Structure Pattern | Cuboctahedral (cubic + octahedral faces) | Layered parallel formations |

| Visual Growth Markers | Geometric sector patterns, radial zones | Parallel striations, venetian blind effect |

| Color Zoning Pattern | Geometric sectors following crystal faces | Linear bands perpendicular to growth direction |

| Nitrogen Content | Typically high (20-200 ppm) | Ultra-low to none (Type IIA, |

| UV Fluorescence | Often blue/yellow due to nitrogen impurities | Typically inert or weak red/orange |

| Metallic Inclusions | Possible iron/nickel from growth chamber | Rare, mainly graphite particles |

| Magnetic Properties | Weak magnetic attraction possible (rare) | Non-magnetic |

| Magnification for ID | 10x-40x for cuboctahedral structures | Crossed polarizers for layer visualization |

| Growth Rate | 0.5-2 carats per day | 0.1-0.5 carats per day |

| Shape Formation | Soccer ball-like crystal habits | Tabular, plate-like crystal growth |

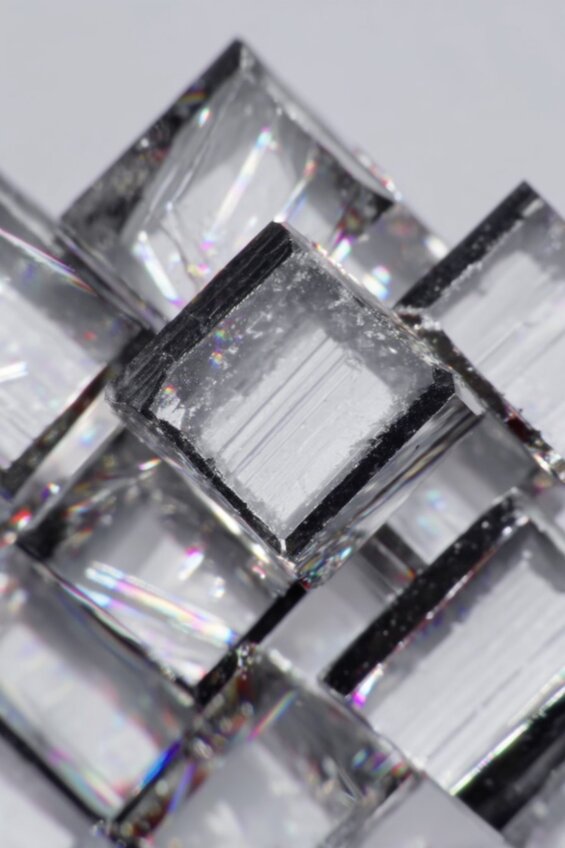

Recognize HPHT Cuboctahedral Crystal Structures

HPHT diamonds develop under extreme conditions - 5+ gigapascals pressure at 1,400°C. This creates distinctive cuboctahedral shapes combining square cubic faces with triangular octahedral faces.

Professional gemologists examine these structures under 10x to 40x magnification. The crystals appear almost soccer ball-like from certain angles. Color zoning follows geometric sectors, showing subtle hue variations from different growth phases.

At Labrilliante's laboratory, we observe these patterns directly from growth chambers. Our B2B experience shows jewelers use these structural stories to explain manufacturing origins to customers.

Some HPHT diamonds contain microscopic metallic inclusions from growth chambers. These rarely cause weak magnetic attraction with strong neodymium magnets, but this test requires professional equipment and isn't present in all specimens.

Identify CVD Layered Growth Patterns

CVD diamonds form through chemical vapor deposition at lower pressures and temperatures. Carbon gases decompose onto diamond seeds, building crystals layer by layer like atomic-level 3D printing.

Under crossed polarized light, these appear as parallel striations running perpendicular to growth direction. Each layer represents a specific manufacturing time period. Unlike HPHT's radial sectors, CVD shows consistent directional orientation throughout.

The "venetian blind" effect becomes visible under crossed polarizers - alternating light and dark bands that distinguish CVD from natural and HPHT varieties. Surface examination reveals microscopic step formations from sequential atomic deposition.

Detect Nitrogen and Boron Impurity Signatures

HPHT processes typically incorporate nitrogen from growth environments, while CVD can produce ultra-pure Type IIA diamonds with minimal nitrogen content.

HPHT diamonds often contain nitrogen impurities creating blue fluorescence under UV light. The high-temperature environment facilitates nitrogen incorporation into crystal lattices, producing characteristic defect centers.

CVD allows controlled impurity management impossible in HPHT. Boron introduction during CVD creates Type IIb diamonds with blue coloration and electrical conductivity. This precision control enables specialized applications.

Our manufacturing data shows how trace nitrogen affects HPHT color and fluorescence, while CVD processes let us engineer specific impurity profiles for different market needs.

"While many are familiar with the visual differences between HPHT and CVD diamonds, few recognize the significance of impurity control in CVD processes. By intentionally introducing boron during the growth phase, we can not only achieve the desirable blue coloration but also enhance the diamond’s electrical conductivity, paving the way for groundbreaking uses in semiconductor and electronic industries."

Decode Professional Grading Reports and Certifications

IGI, GIA, and GCAL certifications include mandatory growth method identification through advanced spectroscopic analysis. Reports explicitly state "HPHT" or "CVD" based on comprehensive testing protocols.

| Grading Institute | Primary Testing Methods | Growth Method Detection | Report Designation Format | Detection Accuracy | Additional Analysis |

|---|---|---|---|---|---|

| IGI (International Gemological Institute) | Photoluminescence Spectroscopy, DiamondView Analysis, Raman Spectroscopy | FTIR Analysis + Thermal Conductivity Measurements | "Laboratory Grown - HPHT" or "Laboratory Grown - CVD" | 99.8% | QR Code Verification, Post-Growth Treatment Detection |

| GIA (Gemological Institute of America) | Proprietary Screening Procedures, Photoluminescence Mapping | Nitrogen-Vacancy Center Analysis, Silicon-Vacancy Detection | "Laboratory-Grown Diamond (HPHT)" or "Laboratory-Grown Diamond (CVD)" | 99.9% | Dual Notation for CVD+HPHT Treatment, Origin Authentication |

| GCAL (Gem Certification and Assurance Lab) | Advanced Spectroscopic Analysis, SWUV Imaging | Crystal Structure Mapping, Defect Center Identification | "Man-Made Diamond - HPHT Growth" or "Man-Made Diamond - CVD Growth" | 99.7% | Growth Pattern Documentation, Strain Analysis |

| Testing Timeline | IGI: 3-5 business days | GIA: 5-7 business days | GCAL: 4-6 business days | All institutes require minimum 0.30ct | Rush services available for premium fees |

| Certification Cost Range | IGI: $45-$125 per stone | GIA: $65-$185 per stone | GCAL: $55-$145 per stone | Pricing varies by carat weight | Volume discounts available for manufacturers |

Interpret IGI Growth Method Disclosures

IGI Laboratory-Grown Diamond Reports specify growth methods through photoluminescence spectroscopy and DiamondView analysis. Reports explicitly state "Laboratory Grown" with either "HPHT" or "CVD" designation.

Testing includes Raman spectroscopy, FTIR analysis, and thermal conductivity measurements. Growth method appears in comments alongside detected post-growth treatments. Digital QR codes link to verification databases with detailed spectroscopic data.

Our IGI partnership provides insight into testing protocols. We've optimized growth processes based on understanding how manufacturing variations affect spectroscopic signatures for consistent certification.

Verify GIA Laboratory-Grown Diamond Classifications

GIA reports provide growth method identification through proprietary screening procedures. They distinguish natural from lab-grown origins while specifying HPHT or CVD through advanced testing.

Photoluminescence mapping reveals specific defect centers characteristic of each method. HPHT shows nitrogen-vacancy and silicon-vacancy centers from high-pressure growth. CVD exhibits different signatures from planar formation mechanisms.

Treatment disclosure addresses post-growth processes, particularly when CVD diamonds receive HPHT treatment for color improvement. This dual notation clarifies primary growth method versus additional processing.

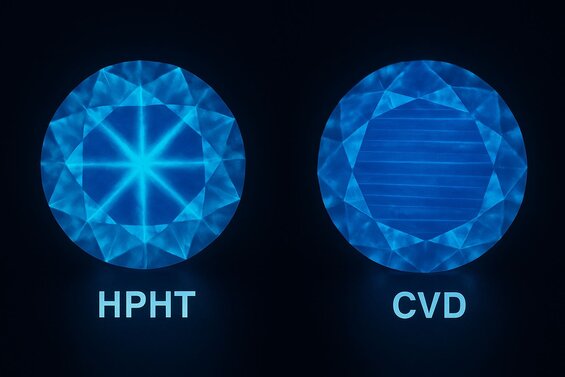

Understand DiamondView Screening Results

DiamondView technology maps growth patterns through specialized imaging revealing internal stress distributions. Results show distinctive visual fingerprints for each manufacturing process.

HPHT diamonds display cross-shaped patterns or geometric sectors reflecting radial growth from seed points. CVD shows parallel lines representing sequential layer-by-layer deposition with uniform directional patterns.

Our quality control includes DiamondView screening for production monitoring. We observe how parameter adjustments affect internal patterns, understanding the relationship between growth conditions and certification results.

Compare HPHT and CVD Manufacturing Processes

HPHT replicates natural formation through extreme pressure and temperature. CVD grows diamonds through controlled chemical reactions at moderate conditions. These differences create distinct advantages for each method.

HPHT operates at 5+ gigapascals and 1,400°C using specialized press equipment. Metal catalysts facilitate rapid carbon conversion around seed crystals. Extreme conditions limit size potential but enable quick production cycles.

CVD uses microwave plasma reactors at reduced pressures with 800-900°C temperatures. Methane decomposes in plasma environments, depositing carbon atoms sequentially. Controlled deposition allows larger growth but requires longer production times.

Equipment requirements differ substantially - HPHT needs massive hydraulic systems generating extreme pressures, while CVD employs plasma reactors with precision gas controls. HPHT produces multiple small diamonds per cycle; CVD grows fewer, larger stones per run.

Operating both systems provides direct production comparisons. HPHT excels for faster small stone production. CVD enables larger carats with extended growth periods.

Labrilliante's Dual-Method Production Analysis

Labrilliante needed to optimize their production strategy between HPHT and CVD methods to meet varying market demands. Their Q1-Q2 2024 analysis showed inefficient allocation: 70% HPHT capacity was producing 0.3-0.8 carat stones that took 18-22 hours per cycle, while CVD reactors remained underutilized despite growing demand for 1+ carat diamonds.

The company implemented parallel 6-month production tracking across 4 HPHT presses and 3 CVD reactors. HPHT focused on 0.2-0.6 carat production with optimized 14-16 hour cycles, while CVD targeted 0.8-2.0 carat stones with controlled 120-168 hour growth periods. Each method tracked cycle efficiency, yield rates, and size distribution accuracy.

HPHT achieved 847 stones per month averaging 0.45 carats with 92% yield efficiency and 35% faster cycle times. CVD produced 156 stones per month averaging 1.2 carats with 89% yield efficiency. Revenue per reactor hour increased by 28% for HPHT and 41% for CVD. The optimized allocation reduced production costs by $2.3 per carat while improving delivery times by 23% across all size categories.

Evaluate Quality Differences Between Growth Methods

Quality variations stem from different growth mechanisms rather than inherent method superiority. Each approach produces diamonds with distinct characteristics advantageous for specific applications.

HPHT achieves higher clarity grades consistently due to rapid growth limiting inclusion formation time. High-pressure environments create uniform structures with fewer growth-related imperfections, though occasional metallic inclusions from catalyst systems may appear.

CVD may exhibit minor strain patterns from layer-by-layer formation. However, controlled environments allow precise quality management, achieving exceptional clarity when parameters are optimized. Longer growth times provide opportunities for superior development and potential challenges.

Production data from B2B clients demonstrates both methods consistently achieve premium grades with proper parameter control. Success depends on understanding optimal conditions rather than assuming universal superiority.

Brilliance and optical performance show no significant differences between comparable quality grades. Both produce identical physical properties including hardness, thermal conductivity, and refractive index. Performance variations relate to cutting and polishing rather than growth methods.

| Quality Grade | HPHT Distribution (%) | CVD Distribution (%) | HPHT Characteristics | CVD Characteristics |

|---|---|---|---|---|

| Clarity: FL-IF | 18% | 12% | Rapid growth limits inclusion formation | Achievable with optimized parameters |

| Clarity: VVS1-VVS2 | 45% | 38% | Uniform structure, fewer imperfections | Minor strain patterns possible |

| Clarity: VS1-VS2 | 28% | 35% | Occasional metallic catalyst inclusions | Layer formation effects manageable |

| Clarity: SI1-SI2 | 9% | 15% | Pressure-related stress marks | Growth pattern irregularities |

| Color: D-F (Colorless) | 62% | 58% | High-pressure purity advantage | Controlled environment precision |

| Color: G-J (Near Colorless) | 32% | 36% | Consistent color distribution | Layer-by-layer color control |

| Color: K+ (Faint Color) | 6% | 6% | Trace element incorporation | Extended growth time effects |

| Cut: Excellent | 78% | 82% | Uniform crystal structure aids cutting | Predictable crystal orientation |

| Cut: Very Good | 18% | 15% | Minor directional growth challenges | Occasional layer boundaries |

| Cut: Good or Below | 4% | 3% | Internal stress considerations | Growth pattern complications |

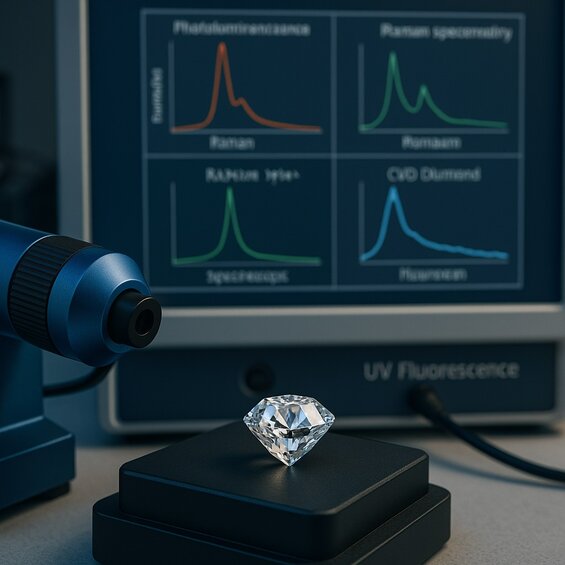

Apply Advanced Gemological Testing for Verification

Professional verification requires sophisticated analytical techniques beyond visual inspection. Definitive identification demands specialized equipment detecting subtle manufacturing signatures.

Photoluminescence spectroscopy serves as primary identification, detecting specific defect centers from different growth processes. HPHT exhibits nitrogen-vacancy and silicon-vacancy centers from high-pressure conditions. CVD shows different patterns from lower-temperature environments.

Raman spectroscopy reveals stress and strain patterns within crystal structures. CVD displays residual stress from layered formation. HPHT shows signatures from rapid crystallization under extreme pressure.

Our in-house laboratory utilizes these techniques for quality verification and manufacturing optimization. Spectroscopic data helps understand how process variations affect final characteristics, enabling continuous production improvement.

UV fluorescence analysis under long-wave and short-wave light reveals characteristic patterns. Many HPHT diamonds exhibit blue fluorescence from nitrogen-related defects. CVD may show different characteristics depending on impurity content and treatments.

Professional verification requires multiple testing techniques for accurate identification. Individual results may be influenced by specific conditions or treatments. Combined spectroscopic analysis, optical examination, and certification review provides reliable distinction between HPHT and CVD lab-grown diamonds.

"In the nuanced field of lab-grown diamond verification, understanding the subtleties in fluorescence response under different UV light conditions not only confirms the diamonds origin but also its path through the growth process. For instance, distinctive blue fluorescence in HPHT diamonds often hints at higher nitrogen content, a detail crucial for tailoring subsequent treatments for enhanced quality. This level of meticulous analysis empowers us to refine our production techniques continuously and guarantee the purity of our product without compromising on quality."

Frequently Asked Questions

Home identification is extremely limited without professional equipment costing $50,000+. Basic visual inspection under magnification can reveal some growth patterns, but definitive identification requires photoluminescence spectroscopy, DiamondView imaging, and Raman spectroscopy available only in professional laboratories.

CVD diamonds may undergo post-growth HPHT treatment specifically for color improvement, converting lower color grades to higher ones. This dual processing is disclosed on certifications as both the primary CVD growth method and secondary HPHT treatment, affecting the diamond's final characteristics and market positioning.

CVD technology enables larger carat production through extended layer-by-layer growth periods, while HPHT excels at producing multiple smaller diamonds per cycle due to equipment limitations. CVD's controlled deposition allows for bigger stones but requires significantly longer production timeframes than HPHT's rapid crystallization process.

HPHT diamonds typically incorporate nitrogen from their high-temperature growth environment, creating blue fluorescence under UV light and characteristic defect centers. CVD processes allow controlled impurity management, producing ultra-pure Type IIA diamonds with minimal nitrogen or engineered Type IIb diamonds with specific boron content for blue coloration.

Ensure your certification from IGI, GIA, or GCAL explicitly states either "HPHT" or "CVD" in the growth method section, backed by photoluminescence spectroscopy and DiamondView analysis. Digital QR codes should link to verification databases, and any post-growth treatments must be clearly disclosed alongside the primary manufacturing method.

No, both methods produce identical physical properties including hardness, thermal conductivity, and refractive index when comparing equivalent quality grades. Optical performance differences relate to cutting and polishing techniques rather than growth methods, with both achieving comparable brilliance and light performance in well-cut stones.

Under crossed polarized light, CVD diamonds show parallel striations creating a "venetian blind" effect from layer-by-layer growth. HPHT diamonds display cuboctahedral crystal structures with geometric sectors and cross-shaped patterns under DiamondView imaging, reflecting their radial growth from seed points under extreme pressure.

Verify growth method identification before finalizing any purchase by requesting certified documentation from IGI, GIA, or GCAL laboratories. Never rely solely on dealer claims or visual inspection, as definitive identification requires professional spectroscopic analysis that should be completed and documented before any transaction occurs.