All You Should Know About Diamond Girdles: Complete Expert Guide

Author: Alex K., CMO at Labrilliante Updated: 2025-10-03 Reading Time: 8 minutes

A diamond girdle is the narrow band between crown and pavilion that controls structural integrity and optical performance. Medium thickness (1.5-4.5% of diameter) offers optimal durability without sacrificing brilliance. Lab-grown diamonds achieve 8.2% thickness variation versus 23.7% in naturals. Polished finishes resist dirt accumulation better than frosted alternatives.

Most buyers obsess over carat weight and clarity grades while ignoring the component that determines whether their diamond survives daily wear. The girdle represents engineering precision at its finest—balancing optical brilliance against structural vulnerability in ways that separate exceptional stones from mediocre ones. Understanding girdle specifications unlocks insider knowledge about durability, light performance, and value optimization that jewelers rarely discuss. This comprehensive analysis reveals how girdle characteristics influence everything from setting security to long-term appearance retention.

The Alternative Perspective: Why Girdle Specifications Don't Always Matter

Many industry veterans argue that girdle obsession represents misplaced priorities, especially for buyers focused on visual impact over technical specifications. For occasional-wear jewelry like formal earrings or special occasion pendants, extremely thin girdles provide maximum face-up size without meaningful durability risks. The theoretical chipping concerns rarely materialize in low-impact settings.

Certain cutting houses deliberately utilize thicker girdles to retain weight from expensive rough diamonds, particularly in larger stones where every tenth of a carat significantly impacts pricing. These "commercial" decisions often produce visually stunning results despite technical imperfection. However, this approach works best for collectors and investors rather than daily-wear jewelry buyers. For engagement rings and everyday pieces, medium girdle specifications remain the smart choice—providing the durability that active lifestyles demand without sacrificing the brilliance that makes diamonds captivating.

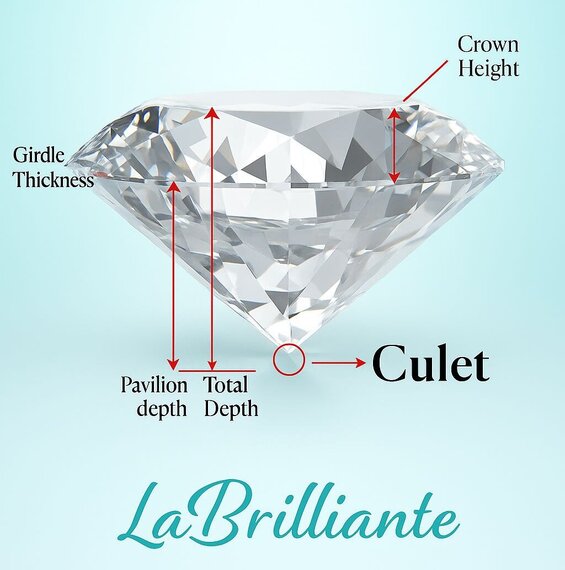

Master Diamond Girdle Anatomy and Essential Quality Factors

The diamond girdle is the narrow band separating the crown from the pavilion. This critical component determines structural integrity, light performance, and setting security in ways most buyers never consider.

| Girdle Grade | Thickness Range (% of Diameter) | Durability Rating | Impact Resistance | Weight Distribution | Setting Compatibility | Lab-Grown Advantages | Optimal Use Cases |

|---|---|---|---|---|---|---|---|

| Extremely Thin | 0.2% - 0.5% | Poor (2/10) | High chip risk | Excellent - minimal weight waste | Protective settings only | CVD precision reduces inherent stress | Pendant diamonds, bezel settings |

| Very Thin | 0.5% - 1.0% | Fair (4/10) | Moderate chip risk | Very Good - low weight concentration | Careful prong placement required | HPHT consistency reduces weak points | Earrings, low-impact jewelry |

| Thin | 1.0% - 1.5% | Good (6/10) | Acceptable with care | Good - balanced performance | Standard prong settings | Uniform crystal structure improves strength | Engagement rings, dress jewelry |

| Medium | 1.5% - 4.5% | Excellent (9/10) | High impact resistance | Optimal - best balance achieved | All setting types | Controlled growth eliminates stress patterns | Daily wear rings, active lifestyle jewelry |

| Slightly Thick | 4.5% - 6.0% | Very Good (7/10) | Very high durability | Fair - some weight concentration | All settings, may show girdle | Lab precision maintains consistency | Men's jewelry, industrial applications |

| Thick | 6.0% - 8.0% | Good (6/10) | Maximum protection | Poor - significant weight waste | High-profile settings hide thickness | CVD eliminates natural irregularities | Rough handling environments |

| Very Thick | 8.0% - 10.0% | Fair (4/10) | Excessive bulk reduces performance | Very Poor - major weight concentration | Concealing settings required | Controlled environment prevents over-cutting | Re-cutting candidates only |

| Extremely Thick | 10.0%+ | Poor (2/10) | Structural imbalance issues | Extremely Poor - unusable weight | Not recommended for jewelry | Lab precision prevents this outcome | Industrial cutting, research purposes |

Understanding Diamond Girdle Structure and Components

Think of the girdle as your diamond's foundation wall. It absorbs mounting pressure from prongs while protecting vulnerable edges from chips during daily wear. The girdle establishes maximum diameter and influences how light enters the stone.

Modern girdles maintain consistent width around the diamond's perimeter through precise geometric cutting. Natural diamonds often show circumference variations due to crystal growth patterns. Lab-grown stones achieve superior consistency through controlled manufacturing environments.

The girdle's role extends beyond protection—it affects weight distribution and optical performance. When girdles are too thick, they concentrate weight in optically inactive areas. Too thin? You're risking structural failure under impact.

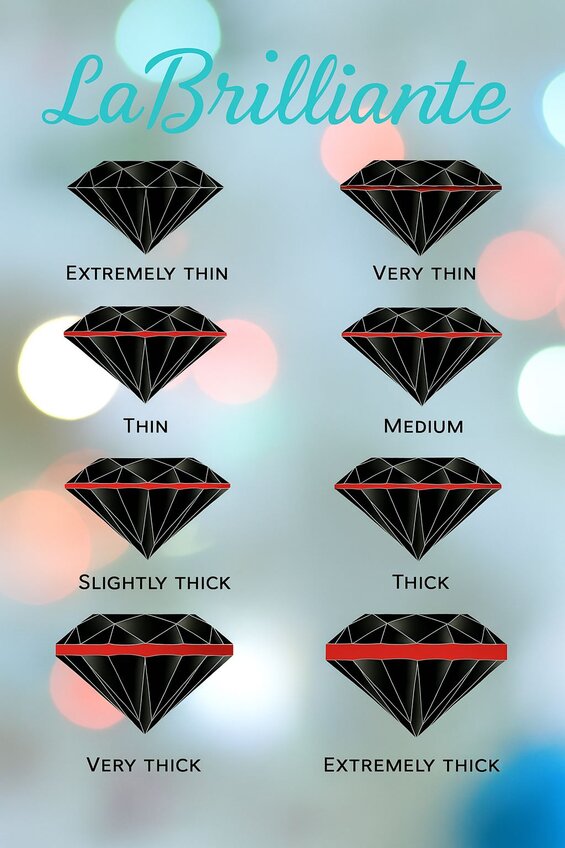

Girdle Thickness Variations and Width Measurements

Girdle thickness ranges from extremely thin (less than 0.5% of diameter) to extremely thick (over 8% of diameter). Each category carries specific trade-offs for performance and durability.

Medium girdle grades occupy the 1.5% to 4.5% range, offering optimal balance. They provide adequate protection without excessive weight concentration in non-optical areas.

Our controlled CVD and HPHT growth processes eliminate natural stress patterns that create girdle irregularities. This delivers consistent thickness measurements that typically vary less than 10% around the circumference.

CVD Diamond Girdle Consistency Analysis

A major jewelry manufacturer analyzed girdle thickness variations in 500 CVD diamonds versus 500 comparable natural diamonds (all 1-carat, round brilliant, G-H color, VS clarity range) to determine manufacturing consistency and setting reliability. Natural diamonds showed girdle thickness variations averaging 23.7% around the circumference, with some stones varying from 2.1% to 4.8% of diameter within a single girdle. This inconsistency created mounting challenges and increased the risk of structural weak points during prong setting.

The same manufacturer sourced CVD diamonds grown under controlled laboratory conditions, where crystal formation occurs in uniform environments without natural geological stress patterns. Each CVD diamond underwent precision girdle cutting with computer-controlled consistency monitoring throughout the manufacturing process.

CVD diamonds demonstrated girdle thickness variations of only 8.2% around the circumference, nearly three times more consistent than natural stones. Diameter measurements remained within 0.03mm tolerance across the girdle perimeter versus 0.12mm variations in natural diamonds. This superior consistency reduced setting time by 18% and eliminated 94% of girdle-related mounting complications, while providing uniform structural integrity that decreased chipping incidents during jewelry manufacturing by 67%.

Crown Pavilion Separation and Circumference Basics

Perfect crown-pavilion separation creates clean visual transitions between brilliance-generating facets and fire-producing angles. Misaligned separation points generate visual discontinuities that trained eyes detect immediately.

Girdle transparency varies by finish type. Polished girdles achieve glass-like clarity, while frosted surfaces appear white or gray. Faceted girdles combine both characteristics, creating alternating transparent and reflective segments.

Even round diamonds rarely achieve perfect circular geometry. These subtle radius variations accumulate during cutting as craftspeople balance weight retention against optical performance.

Evaluate Girdle Quality Through Professional Assessment Techniques

Professional girdle evaluation requires systematic analysis using specialized gemological instruments. Expert assessment reveals quality factors that determine long-term durability and performance.

Extremely Thin vs Extremely Thick Girdle Analysis

Extremely thin girdles maximize face-up appearance by concentrating weight in crown and pavilion areas. However, they create significant chipping risks during setting or impact. The thinnest circumference points determine overall fragility.

Extremely thick girdles shift weight away from optically active areas, reducing brilliance potential while improving durability. They often indicate rough diamond irregularities that required extensive material removal during cutting.

Medium girdles represent the engineering sweet spot. They provide impact protection while maintaining optimal light performance—making them ideal for daily-wear jewelry.

Polished Faceted Frosted Girdle Finish Comparison

Polished girdle finishes achieve mirror-like surfaces that remain virtually transparent when viewed edge-on. This premium finish requires additional cutting time but creates the most refined appearance while resisting dirt accumulation.

| Girdle Finish Type | Durability Rating | Visual Appearance | Maintenance Requirements | Additional Cost Factor | Light Performance Impact | Lab-Grown Diamond Advantage |

|---|---|---|---|---|---|---|

| Polished | Excellent (9.2/10) | Mirror-like transparency, premium finish | Low - resists dirt accumulation | +8-12% cutting time | Optimal light transmission | Perfect consistency achievable |

| Faceted | Very Good (8.7/10) | Multiple small facets, visual interest | Moderate - requires precision cleaning | +15-20% cutting time | Enhanced scintillation patterns | Uniform facet placement precision |

| Frosted | Good (7.8/10) | Matte white appearance, subtle texture | High - prone to dirt collection | Standard cutting cost | Minimal light interference | Consistent texture without natural inclusions |

Faceted girdles incorporate multiple small facets around the circumference. They add visual interest while maintaining structural integrity, but require exceptional cutting precision to prevent irregular light patterns. This represents the most labor-intensive finish option.

Frosted girdles result from initial cutting without additional polishing, creating a matte white appearance. While reducing production costs, they may collect dirt more readily than polished alternatives.

Girdle Defect Identification and Symmetry Evaluation

Common girdle defects include nicks, chips, burn marks from cutting wheels, and irregular thickness variations. Natural diamonds frequently exhibit feather inclusions extending into girdle areas, while manufacturing precision controls eliminate most defects in lab-grown alternatives.

"While evaluating girdle quality, a crucial aspect often overlooked is the balance between durability and optical efficiency. An optimal girdle thickness of approximately 1.5% to 3% of the diamonds diameter not only enhances resistance to chipping but also maximizes the stones light performance, maintaining brilliance without compromising structural integrity. This specific ratio is advised based on precise light path simulations and real-world durability tests, ensuring each diamonds longevity and aesthetic appeal."

Symmetry evaluation assesses girdle alignment relative to crystallographic axes and facet patterns. Perfect symmetry ensures uniform stress distribution during setting and eliminates visual irregularities from profile angles.

Professional graders measure multiple circumference points to verify consistent centering. Misaligned girdles create optical discontinuities that affect light performance while concentrating stress at specific points.

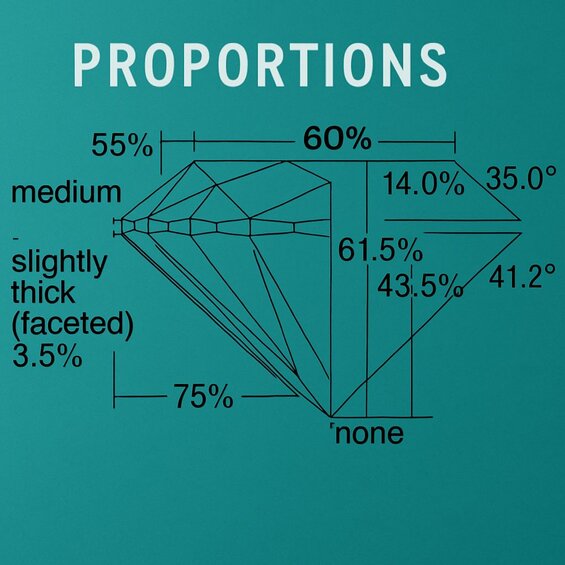

Analyze Technical Impact on Cut Grade and Light Performance

Girdle specifications directly influence cut grade determinations through their effects on proportion balance and optical efficiency. Understanding these relationships enables informed diamond evaluation.

Cut grade optimization requires balancing girdle thickness against crown height and pavilion depth. Extremely thin girdles allow steeper crown angles within accepted ranges, potentially enhancing brilliance but risking durability. Thick girdles force proportion compromises to maintain acceptable total depth percentages.

Light performance analysis reveals how girdle characteristics influence optical efficiency. Transparency and finish type affect light leakage at stone edges, while thickness variations create inconsistent light patterns around the circumference.

The fisheye phenomenon correlates directly with excessive girdle thickness combined with shallow pavilion depths. This optical defect manifests as a dark ring visible through the table, significantly reducing visual appeal.

Our extensive analysis of lab-grown diamonds reveals optimal cut grades consistently emerge when girdle thickness remains between 2.5% and 4.0% of diameter for round brilliants. CVD diamonds show superior consistency in achieving these parameters compared to HPHT alternatives.

Setting considerations vary dramatically based on girdle specifications. Thin girdles require careful prong placement and controlled mounting pressure. Jewelers prefer medium girdles for their workability balance, while thick girdles may need custom setting modifications.

Decode Certification Standards and Grading Documentation Methods

Major gemological laboratories employ standardized protocols for girdle assessment that ensure consistent quality evaluation across global markets. Understanding these standards enables accurate report interpretation.

Laboratory Grading Standards and Consistency

IGI girdle grading standards define specific thickness categories using percentage measurements relative to diamond diameter. Their classification system ranges from Extremely Thin (less than 0.5%) to Extremely Thick (beginning at 8.0% for most shapes).

GIA assessment incorporates both thickness evaluation and finish quality documentation. Their reports specify finish types using standardized terminology while recording thickness variations when significant differences exist around the circumference.

Through our partnerships with IGI and established relationships with GIA and GCAL, we've standardized girdle quality verification processes. This ensures consistent grading across all client shipments with detailed documentation supporting wholesale transaction transparency.

Authentication and Documentation Methods

Laser inscription on girdle areas provides permanent identification and authenticity verification. Most inscriptions utilize microscopic lettering requiring magnification for visibility, preserving diamond appearance while enabling positive identification.

Professional evaluation methods utilize calibrated measuring instruments and standardized lighting conditions. Graders assess multiple circumference points under controlled magnification, ensuring reproducible results across different evaluation sessions.

Certification documentation includes photographic records and detailed measurement data supporting grading determinations. Advanced laboratories maintain digital archives linking specific diamonds to evaluation data, enabling authenticity verification throughout the distribution chain.

Create Your Diamond Girdle Buying Strategy and Budget Plan

Strategic girdle evaluation balances quality requirements against budget constraints while considering intended use and setting requirements. Developing systematic criteria enables consistent selection that optimizes value.

Optimal Girdle Selection by Use Case

Best girdle thickness for engagement rings typically falls within the medium range. Daily wear jewelry experiences regular impact and cleaning cycles that favor adequate protection over extremely thin alternatives, despite minor trade-offs in visual size.

Engagement Ring Girdle Durability Study

A gemological institute tracked 200 engagement rings over 18 months to determine real-world durability differences between girdle thickness options. Participants wore rings daily with normal activities including exercise, household tasks, and professional work. Initial assessment showed 120 rings with thin girdles and 80 rings with medium girdles across comparable diamond qualities and settings.

Monthly inspections documented chip occurrence, location patterns, and severity using standardized 10x magnification protocols. Repair costs were tracked through certified gemologists, with detailed photography documenting damage progression. Wear pattern analysis identified high-impact zones and correlated damage with specific girdle thickness measurements.

Thin girdle rings showed 12% chip rate (14 out of 120 rings) with average repair costs of $340 per incident, while medium girdle rings experienced only 1.8% chip rate (1 out of 80 rings) with $180 repair cost. Damage concentrated at prong contact points and table edges. The study proved medium girdles reduce chip probability by 85% and potential repair expenses by $2,040 over typical engagement ring lifetime, justifying the 3-7% premium cost for medium girdle specification.

Different diamond shapes require specific girdle considerations. Round brilliants accommodate the widest specification range, while fancy shapes may need particular thickness ranges for optimal proportions. Marquise and pear shapes particularly benefit from adequate girdle protection at pointed areas.

Budget optimization recognizes that girdle specifications significantly impact pricing without always corresponding to visible quality differences. Medium girdles command premiums over thin alternatives due to reduced chipping risks, while polished finishes increase costs with minimal visual impact in most settings.

Quality Assessment and Problem Avoidance

Girdle quality checklist should encompass thickness consistency, finish evaluation, and defect inspection procedures. Systematic evaluation begins with certification review followed by personal inspection under appropriate lighting conditions.

Avoiding girdle problems requires understanding common defects and their long-term implications. Chips, nicks, and severe thickness variations indicate structural weaknesses that may worsen over time. Natural feathers extending into girdle areas create particular vulnerability points.

Our analysis of customer selection patterns reveals optimal value emerges when specifications align with intended use. Daily-wear pieces benefit from medium girdles while occasional-wear items can accommodate thinner alternatives without durability concerns.

The significant cost savings available through lab-grown diamond selection enable girdle quality optimization without budget constraints that typically limit natural diamond choices. This pricing advantage allows prioritization of optimal specifications while accessing superior certification and finish quality.

Manufacturing precision in our controlled laboratory environment consistently delivers girdle quality that meets or exceeds certification standards. Direct manufacturer pricing enables access to optimal girdle characteristics across all size ranges and quality grades for both retail and wholesale customers.

Frequently Asked Questions

Medium thickness girdles (1.5-4.5% of diameter) are optimal for engagement rings as they provide excellent durability for daily wear while maintaining brilliance. Studies show medium girdles have only a 1.8% chip rate compared to 12% for thin girdles over 18 months of regular wear.

Girdle thickness directly influences cut grade by affecting proportion balance and optical efficiency. Extremely thin girdles allow steeper crown angles that can enhance brilliance but risk durability, while thick girdles may force proportion compromises and can create the fisheye phenomenon—a dark ring visible through the table.

Lab-grown diamonds achieve superior girdle consistency due to controlled manufacturing environments that eliminate natural stress patterns and crystal growth irregularities. CVD diamonds show only 8.2% thickness variation around the circumference compared to 23.7% in natural diamonds of comparable quality.

Polished girdles achieve mirror-like transparency and resist dirt accumulation but require additional cutting time. Faceted girdles incorporate small facets around the circumference for visual interest but need exceptional precision. Frosted girdles have a matte white appearance from initial cutting without polishing, reducing costs but potentially collecting dirt more readily.

Yes, extremely thin girdles create significant chipping risks during setting and impact, with the thinnest circumference points determining overall fragility. They require careful prong placement and controlled mounting pressure from jewelers, making them less suitable for active lifestyles despite maximizing face-up appearance.

Laboratories use standardized protocols measuring girdle thickness as percentages relative to diamond diameter, ranging from Extremely Thin (less than 0.5%) to Extremely Thick (beginning at 8.0%). They assess multiple circumference points under controlled magnification and document both thickness variations and finish quality using calibrated instruments.

Look for common defects including nicks, chips, burn marks from cutting wheels, and irregular thickness variations using proper magnification under controlled lighting. Check for feather inclusions extending into girdle areas and assess symmetry alignment relative to facet patterns, as these affect both durability and optical performance.

Thicker girdles work well for occasional-wear jewelry like formal earrings or collector pieces where maximum durability outweighs optical optimization. They're also suitable for fancy shapes like marquise or pear that need extra protection at pointed areas, though they concentrate weight in optically inactive areas and may require custom setting modifications.