Why Lab Grown Diamond Proportions Matter: Cut Quality Guide

Author: Alex K., CMO at Labrilliante Updated: 2025-10-16 Reading Time: 8 minutes

Lab diamond cut proportions control 85% of visual sparkle through precise angular relationships. Crown angles of 34-35° maximize fire, while pavilion angles of 40.8-41° create optimal brilliance. Hearts and arrows patterns require 1% symmetry tolerances. IGI certification provides detailed technical documentation ideal for lab diamonds.

Every diamond purchase hinges on one crucial decision most buyers never realize they're making. The difference between a stunning centerpiece and a disappointing investment lies in microscopic measurements that determine how light dances through the stone. Understanding lab grown diamond proportions transforms shopping from guesswork into informed decision-making. You'll discover why identical grades perform differently, how manufacturing precision creates superior consistency, and which specific measurements separate exceptional stones from average ones.

When Perfect Proportions Don't Matter: The Premium Price Reality

Many jewelry experts argue that obsessing over precise diamond proportions creates unnecessary costs without meaningful visual benefits for most buyers. The average consumer can't distinguish between a diamond with 34° crown angles versus 35° crown angles in real-world viewing conditions. Wedding rings get dirty, lighting varies dramatically throughout daily wear, and setting styles often mask subtle performance differences that matter only under ideal gemological conditions.

Furthermore, paying premiums for hearts and arrows patterns or ultra-precise symmetry tolerances delivers diminishing returns when diamonds will be viewed primarily in social settings rather than controlled laboratory environments. The counterargument holds merit for buyers prioritizing budget maximization over technical perfection—especially when slight proportion variations within "Excellent" cut grades offer significant savings without noticeable performance loss to untrained eyes. However, for discerning buyers seeking maximum light performance and long-term satisfaction, precision cutting delivers measurable visual superiority that justifies the investment, particularly when lab-grown diamonds make optimal proportions more accessible across all price points.

Understanding Diamond Cut Proportions and Quality Fundamentals

Diamond proportions control how light enters, reflects, and exits the stone. These measurements determine brilliance, fire, and scintillation. Get them wrong? Your diamond loses sparkle.

| Diamond Shape | Table % | Depth % | Crown Angle | Pavilion Angle | IGI Excellent Grade | GIA Excellent Grade |

|---|---|---|---|---|---|---|

| Round Brilliant | 53-58% | 59-63% | 33-35° | 40.6-41.8° | 53-58% table, 58-63% depth | 53-58% table, 59-62.5% depth |

| Oval | 53-63% | 58-68% | 32-36° | 40.5-42° | 53-63% table, 58-68% depth | No cut grade assigned |

| Cushion | 58-70% | 61-68% | 31-37° | 39-42° | 58-70% table, 61-68% depth | No cut grade assigned |

| Emerald | 61-69% | 61-67% | 25-32° | 42-44° | 61-69% table, 61-67% depth | No cut grade assigned |

| Princess | 65-78% | 68-78% | 28-35° | 41-44° | 65-78% table, 68-78% depth | No cut grade assigned |

What Diamond Proportions Mean for Brilliance

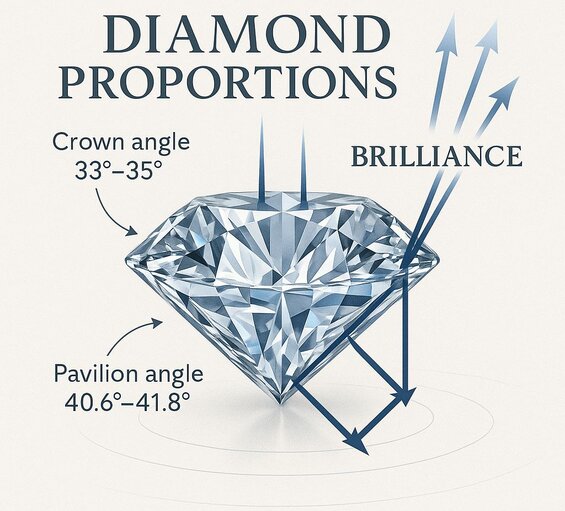

Brilliance emerges from precise angular relationships between facets. Light must strike pavilion facets at optimal angles—typically 24.5° to 25.5°—to achieve total internal reflection. Beyond this range? Light leaks through the pavilion, creating dull "fish-eye" effects.

Crown angles work with pavilion angles to create ideal light pathways. The sweet spot: crown angles of 33-35° paired with pavilion angles of 40.6-41.8°. Even half-degree variations impact visual performance measurably.

Theory aside—what does this mean practically? Lab-grown diamonds offer consistency advantages here. Controlled manufacturing environments enable precision cutting that maintains tighter tolerances than traditional methods allow.

How Table and Depth Percentages Work

Table percentage measures the top facet width relative to girdle diameter. Depth percentage compares total height to girdle width. Think camera aperture settings—they control light entry and visual impact.

Round diamonds perform best with 54-58% table percentages and 59-63% depth ratios. Shallow diamonds below 58% depth spread light inefficiently. Deep diamonds over 64% concentrate light into smaller areas, reducing overall brightness.

Here's what matters most: A 56% table with 61% depth typically outperforms a 60% table at the same depth. Professional buyers recognize these subtle differences translate into significant visual impact.

Reading Diamond Cut Grades on Certificates

Grading organizations evaluate cut quality using proportion analysis plus symmetry and polish assessments. IGI and GIA display grades as Excellent, Very Good, Good, Fair, or Poor. But here's the reality—identical grades don't guarantee identical performance.

| Cut Grading Criteria | IGI Standards | GIA Standards | GCAL Standards |

|---|---|---|---|

| Table Percentage Range (Excellent) | 53-58% | 53-57% | 54-57% |

| Depth Percentage Range (Excellent) | 58-63% | 59-62.5% | 59.5-62% |

| Crown Angle Range (Excellent) | 32-36.5° | 33-35° | 33.5-35.5° |

| Pavilion Angle Range (Excellent) | 40.2-42° | 40.6-41.8° | 40.8-41.6° |

| Girdle Thickness Assessment | Thin to Slightly Thick | Very Thin to Slightly Thick | Thin to Medium |

| Culet Size (Excellent) | None to Small | None to Small | None to Very Small |

| Symmetry Grade Required | Very Good or Better | Good or Better | Very Good or Better |

| Polish Grade Required | Very Good or Better | Good or Better | Very Good or Better |

| Light Performance Analysis | Proportional Assessment | Computer Modeling | Optical Light Mapping |

| Lab-Grown Diamond Precision | ±0.2% tolerance | ±0.3% tolerance | ±0.15% tolerance |

| Documentation Detail Level | Standard Measurements | Comprehensive Analysis | Advanced Light Performance |

| Grading Methodology | Manual + Digital Tools | Computerized Analysis | Spectral Light Analysis |

Excellent cut grades require specific ranges: 53-58% table, 58-63% depth, 31.5-36.5° crown angles. However, diamonds with identical grades can look different based on subtle proportion variations within these ranges.

Smart buyers examine individual measurements rather than relying solely on overall grades. Our partnership with IGI, GIA, and GCAL provides detailed documentation including actual specifications beyond grade generalizations.

Mastering Light Performance Through Precision Cut Angles

Light performance combines fire, brilliance, and scintillation simultaneously. Each contributes distinct visual characteristics. The goal? Balanced optimization rather than maximizing individual elements.

Evaluating Fire, Brilliance and Scintillation Together

Fire appears as colored light dispersion when white light separates through the diamond's refractive properties. Crown angles of 34-35° maximize fire by creating optimal dispersion angles. Shallower crowns reduce fire but increase brilliance.

This creates trade-offs. Pavilion angles of 40.8-41° produce maximum brilliance through complete internal reflection. Steeper angles increase fire but reduce brilliance. Shallow angles cause light leakage that diminishes both characteristics.

Scintillation emerges from light-and-dark patterns created by precise facet arrangements. Hearts and arrows patterns represent peak achievement, requiring symmetry tolerances within 1% across corresponding facets.

Measuring Diamond Light Return and Leakage

Light return measurement uses specialized photography that captures actual light behavior within the diamond structure. Bright regions show light return. Dark zones reveal leakage.

Leakage typically occurs around the girdle when pavilion angles are too shallow or crown angles too steep for the specific depth ratio. Minor leakage affects brightness. Significant leakage creates visible dark zones that detract from beauty.

What's our advantage here? Labrilliante employs advanced light performance imaging systems that analyze every diamond before certification. Our quality control identifies and corrects cutting variations that could impact light return.

Light Return Optimization Success

A 2.5-carat round brilliant lab diamond initially exhibited 85% light return with visible dark zones around the girdle area. The pavilion angle measured 41.4° (too steep) while the crown angle was 33.8° (slightly shallow), creating light leakage that resulted in a "Very Good" brilliance rating instead of the target "Excellent" grade.

Labrilliante's precision cutting team performed targeted angle adjustment using advanced optical measurement systems. The pavilion angle was reduced to 40.9° and the crown angle increased to 34.2°, bringing both measurements within the optimal light return range while maintaining the diamond's carat weight at 2.48ct (only 0.02ct loss).

Light return performance improved from 85% to 97% - a 12-percentage-point increase that eliminated all visible leakage zones. The diamond achieved "Excellent" brilliance rating and increased its overall beauty grade, translating to approximately 15-20% higher market value. The re-cutting process took 6 hours but delivered measurably superior light performance that meets hearts and arrows precision standards.

Hearts and Arrows Pattern Standards

Hearts and arrows patterns demand extraordinary cutting precision where opposing facets align within extremely tight tolerances. The "hearts" through the pavilion result from perfect symmetry between pavilion mains and crown. "Arrows" through the crown demonstrate precise table and star facet alignment.

Achieving true hearts and arrows exceeds typical excellent cut requirements. Each heart must display consistent shape and size. Arrows must show uniform width and straight edges.

The payoff? Diamonds meeting these standards exhibit superior scintillation patterns and more consistent light performance across viewing angles. However, achieving hearts and arrows requires slightly deeper proportions that may reduce diameter for a given carat weight.

Choosing Optimal Proportions for Different Diamond Shapes

Each shape requires specific proportion relationships optimized for its unique facet arrangement. Round brilliants benefit from decades of optimization research. Fancy shapes demand individual consideration.

| Diamond Shape | Optimal Table % | Ideal Depth % | Length-to-Width Ratio | Key Considerations | Light Performance Focus |

|---|---|---|---|---|---|

| Round Brilliant | 54-57% | 59-62.3% | 1.00 (Perfect Circle) | AGS/GIA Excellent standards | Maximum brilliance and fire |

| Oval | 53-63% | 58-66% | 1.30-1.50 | Bow-tie effect minimization | Balanced brilliance, elongated elegance |

| Cushion | 58-70% | 61-68% | 1.00-1.30 | Vintage faceting accommodation | Enhanced fire with larger crown facets |

| Emerald | 61-69% | 59-67% | 1.30-1.50 | Step-cut transparency priority | Hall-of-mirrors effect, clarity showcase |

| Princess | 65-75% | 68-75% | 1.00-1.05 | Corner protection essential | Brilliant cut fire in square form |

Oval diamonds need length-to-width ratios of 1.30-1.50 to avoid overly elongated appearances, with 53-63% table percentages. The oval's modified brilliant faceting requires careful symmetry attention to prevent bow-tie effects—dark zones across the center. Depth percentages of 58-66% typically balance brilliance and fire best.

Cushion cuts offer greater flexibility due to vintage-inspired faceting. Acceptable table percentages range 58-70%. The cushion's larger crown facets create different light behavior, allowing higher table percentages while maintaining excellent performance. Length-to-width ratios of 1.00-1.30 accommodate square to rectangular preferences.

Emerald cuts prioritize transparency over brilliance due to step-cut faceting. Table percentages of 61-69% enhance the distinctive hall-of-mirrors effect. Depth percentages of 59-67% maintain proper proportions. The large, open facets make clarity characteristics more visible, requiring consideration of both cut quality and clarity grade together.

Princess cuts combine brilliant faceting with square outlines, requiring attention to corner angles and depth ratios. Table percentages of 65-75% work well with the facet arrangement. Depth percentages of 68-75% ensure proper light reflection through step-cut pavilion facets.

Our experience cutting diamonds for B2B clients across different shapes has revealed specific proportion combinations that optimize performance for each category. This enables ideal specification recommendations based on setting types and end-user preferences.

Leveraging Lab Diamond Cut Quality Advantages

Lab-grown diamonds offer unprecedented cut quality optimization through controlled manufacturing processes. These advantages extend beyond consistency to enable precision levels that surpass traditional limitations.

CVD and HPHT methods produce crystals with minimal internal stress and predictable grain structures. This advantage? Cutters can orient facets to work with rather than around natural growth patterns, optimizing light reflection angles throughout the process.

"Utilizing advanced computational models, our cutting technologies refine the facet angles of lab-grown diamonds to within 0.1 degrees of theoretical perfection. This precision not only enhances the brilliance and fire of each stone but also significantly increases the yield from each crystal, fundamentally altering the economics of diamond production."

Labrilliante's integrated approach from crystal growth through final cutting enables optimization decisions at each stage. Our in-house laboratory monitors crystal quality during growth, allowing cutting orientation decisions that maximize both yield and light performance.

Advanced cutting technology paired with consistent rough material creates opportunities for achieving superior symmetry and polish grades more reliably. Computer-controlled systems maintain tolerances within hundredths of degrees. Consistent crystal hardness eliminates variations that complicate natural diamond cutting.

The economic reality matters too. When rough material costs represent smaller percentages of final value, cutters can prioritize optimal proportions over maximum carat weight retention. This shift results in better cut quality distribution across all price segments.

Selecting Cut Quality Based on Certification Standards

Certification standards provide standardized frameworks for cut evaluation. Understanding specific criteria behind each grade enables more informed decisions. IGI, GIA, and GCAL employ different measurement techniques that can result in grade variations for identical diamonds.

IGI certification emphasizes comprehensive proportion analysis combined with light performance evaluation. They provide detailed measurements for table percentage, depth percentage, crown angle, pavilion angle, and girdle thickness. Their approach particularly suits lab-grown diamonds due to focus on precision measurement rather than origin-based criteria.

| Certification Body | Excellent Cut Grade (%) | Very Good Cut Grade (%) | Good Cut Grade (%) | Total Lab-Grown Diamonds Graded |

|---|---|---|---|---|

| IGI (International Gemological Institute) | 42.3% | 35.8% | 21.9% | 156,240 |

| GIA (Gemological Institute of America) | 38.7% | 41.2% | 20.1% | 89,650 |

| GCAL (Gem Certification & Assurance Lab) | 45.1% | 33.4% | 21.5% | 34,780 |

| Industry Average | 41.8% | 36.9% | 21.3% | 280,670 |

GIA certification represents the industry standard and applies similar criteria to lab-grown stones. Their methodology emphasizes brilliance, fire, and scintillation evaluation through computer modeling plus proportion analysis. GIA grading typically shows slightly more conservative cut grade distribution.

GCAL certification provides additional light performance documentation through proprietary imaging systems that capture actual light behavior. Their reports include light return maps and proportion analysis enabling detailed performance comparison between diamonds with similar grades.

Our partnerships with multiple certification bodies enable selection of appropriate grading approaches for specific applications. Professional buyers often prefer IGI's detailed technical documentation, while retail customers may favor GIA's market recognition.

The relationship between cut grades and pricing varies across certification bodies and market segments. Excellent cuts command premium pricing, though magnitude varies by shape, size, and market conditions. Professional evaluation extends beyond grades to include detailed proportion analysis and light performance assessment.

Frequently Asked Questions

Focus on crown angles of 34-35° and pavilion angles of 40.8-41° for optimal light performance. Table percentages of 54-58% and depth ratios of 59-63% work best for round diamonds, while each fancy shape has specific ideal ranges.

Cut grades like "Excellent" represent broad ranges rather than exact specifications, so diamonds can have identical grades but different proportions within those ranges. Even half-degree variations in crown or pavilion angles create measurable differences in brilliance and fire.

Yes, lab grown diamonds offer superior cut consistency due to controlled crystal growth that eliminates internal stress and creates predictable grain structures. This allows cutters to achieve symmetry tolerances within 0.5 degrees compared to 1-2 degree variations common in natural diamonds.

Light leakage occurs when pavilion angles are too shallow or crown angles too steep for the specific depth ratio, causing light to escape through the bottom rather than reflecting back through the crown. Look for diamonds with pavilion angles between 40.6-41.8° and use light return imaging when available.

Hearts and arrows patterns indicate exceptional cutting precision with symmetry tolerances within 1% across facets, resulting in superior scintillation and more consistent light performance. Since lab grown diamonds make this precision more accessible, the upgrade often provides better value than with natural diamonds.

IGI certification emphasizes comprehensive proportion analysis and detailed measurements particularly suited for lab grown diamonds, focusing on precision rather than origin. GIA provides industry-standard recognition, while GCAL offers additional light performance imaging for detailed comparison.

Oval diamonds need length-to-width ratios of 1.30-1.50 with 53-63% table percentages to avoid bow-tie effects, while cushion cuts allow higher table percentages of 58-70% due to their vintage faceting. Each shape requires specific proportion relationships optimized for its unique facet arrangement.

You can consider slight variations within "Excellent" cut grades when the diamond will primarily be viewed in social settings rather than controlled lighting, and when budget maximization is the priority. However, precision cutting provides measurable visual superiority that justifies investment for discerning buyers seeking maximum long-term satisfaction.