How Big Can Lab Grown Diamonds Be? The Ultimate Size Guide

Author: Alex K., CMO at Labrilliante Updated: 2025-10-07 Reading Time: 12 minutes

Lab grown diamonds can reach 155 carats—the current world record—with CVD technology scaling infinitely while HPHT methods max out around 35 carats due to pressure constraints. Production time increases exponentially: 10-carat stones require 3-4 months versus weeks for smaller diamonds, but cost advantages over natural stones actually improve with size.

The diamond industry stands at a technological crossroads where size limitations have become virtually obsolete. How big can lab grown diamonds be? The answer challenges everything we thought we knew about precious stone formation and availability. Lab-created diamonds are rewriting the rules of what's possible in gemstone size, offering collectors and investors access to extraordinary specimens that would be impossible to find naturally. This comprehensive guide reveals the cutting-edge science, breakthrough achievements, and practical considerations that determine maximum diamond sizes in today's laboratory environments.

The Reality Check: Why Massive Lab Diamonds May Not Be Worth It

While lab technology can theoretically create enormous diamonds, the practical limitations tell a different story. Production times extending 5-6 months for truly large stones create massive opportunity costs and tie up expensive equipment that could produce multiple smaller, more marketable diamonds. The exponential increase in energy consumption and defect probability means that many large diamond attempts fail completely, representing total loss of months of investment.

Market demand presents another challenge entirely. Consumer preference consistently favors 1-3 carat diamonds for engagement rings and jewelry, while stones exceeding 10 carats become increasingly difficult to sell outside of specialized collector markets. The cost savings compared to natural diamonds, while substantial, still result in absolute prices that limit the customer base significantly. Most jewelers lack experience handling massive lab diamonds, and insurance costs increase dramatically with size, creating additional barriers to practical ownership.

Understanding Maximum Lab Diamond Size Potential

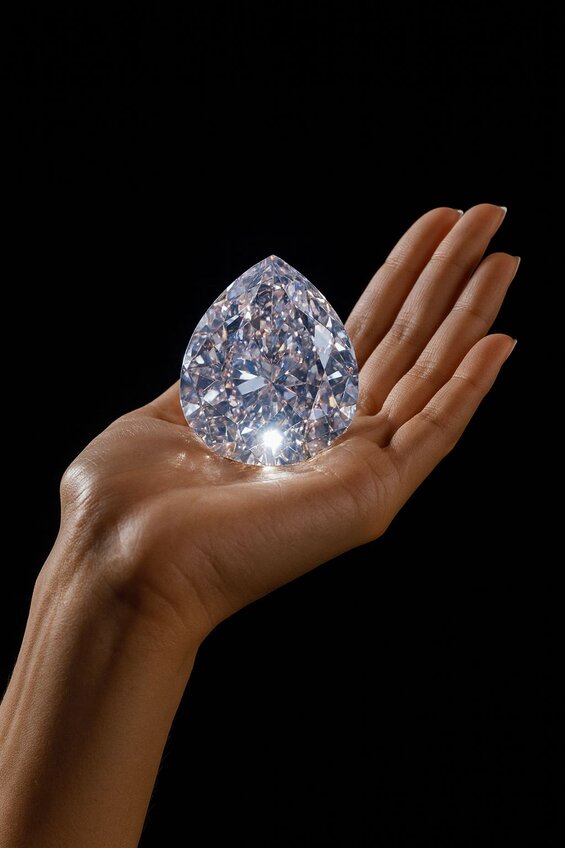

Lab grown diamonds can reach extraordinary sizes, with the current world record standing at 155 carats. This dwarfs most natural diamonds and proves that synthetic stones face virtually no size limitations beyond current technology and production resources.

Unlike natural diamonds constrained by geological processes over billions of years, lab diamonds grow in controlled environments. Natural formation depends on random carbon availability, temperature fluctuations, and geological disturbances deep in Earth's mantle. Lab creation eliminates these variables entirely.

The trade-off? Larger stones demand exponentially longer production times and higher energy consumption. A 10-carat lab diamond doesn't simply take twice as long as a 5-carat stone to produce – the relationship scales dramatically as size increases.

| Carat Size | Production Time (Days) | Energy Consumption (kWh) | Production Cost per Carat | Total Production Cost | Growth Method |

|---|---|---|---|---|---|

| 1 Carat | 7-10 | 1,200 | $400 | $400 | CVD/HPHT |

| 2 Carat | 12-18 | 2,800 | $500 | $1,000 | CVD/HPHT |

| 5 Carat | 25-35 | 8,500 | $650 | $3,250 | CVD/HPHT |

| 10 Carat | 45-65 | 22,000 | $800 | $8,000 | CVD Primary |

| 20 Carat | 75-95 | 55,000 | $1,100 | $22,000 | CVD Only |

| 35 Carat | 105-130 | 125,000 | $1,450 | $50,750 | CVD Only |

| 50 Carat | 125-155 | 210,000 | $1,800 | $90,000 | CVD Only |

| 100 Carat | 140-170 | 485,000 | $2,500 | $250,000 | CVD Only |

| 155 Carat | 150-180 | 850,000 | $3,200 | $496,000 | CVD Only |

At Labrilliante's manufacturing facilities, we've observed how size scaling affects every production variable. Most commercial demand centers around 1-5 carat stones, though we've successfully produced much larger specimens for specialized applications.

155 Carat World Record Breakthrough Explained

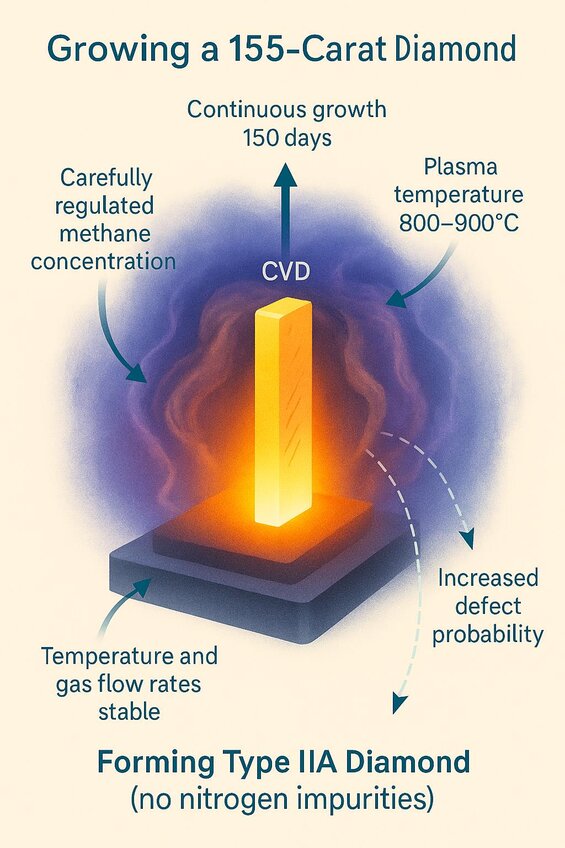

The 155-carat achievement required approximately 150 days of continuous Chemical Vapor Deposition growth. Plasma temperatures stayed precisely at 800-900°C while methane concentrations remained carefully regulated throughout the entire process.

This record-breaking stone exhibits Type IIA characteristics – virtually no nitrogen impurities. Such quality is extremely rare in natural diamonds of comparable size. Any fluctuations in gas flow rates, substrate temperature, or plasma stability could have compromised the entire growth cycle.

However, achieving massive sizes creates significant challenges. Longer growth periods increase crystalline defect probability and demand unprecedented environmental controls. Most producers focus on smaller sizes where quality control stays manageable.

CVD vs HPHT Size Limitations Compared

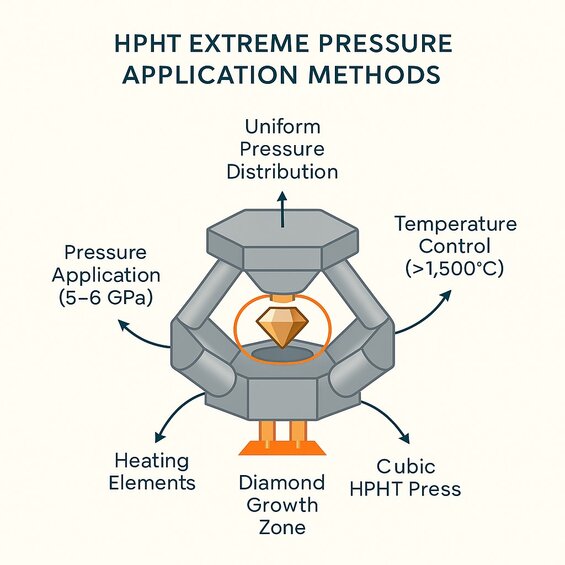

Chemical Vapor Deposition demonstrates superior scalability compared to High Pressure High Temperature methods. CVD processes can theoretically continue indefinitely since they rely on continuous gas deposition rather than pressure constraints. The largest CVD diamonds exceed 150 carats, while HPHT production typically maxes out around 35 carats.

HPHT faces physical press limitations. The required pressures of 5-6 GPa become increasingly difficult to maintain across larger growth chambers. As press size increases, maintaining uniform pressure and temperature distribution becomes exponentially more complex.

| Production Method | Maximum Achievable Size (Carats) | Production Timeframe | Technical Limitations | Quality Consistency | Energy Requirements |

|---|---|---|---|---|---|

| CVD (Chemical Vapor Deposition) | 155+ carats (current record) | 100-150 days for 100+ carat stones | Time-dependent defect accumulation, plasma stability maintenance | High - fewer variables to control | Moderate - continuous low pressure process |

| HPHT (High Pressure High Temperature) | 35 carats (practical maximum) | 7-14 days for maximum size stones | Press chamber size constraints, uniform pressure distribution challenges | Variable - pressure uniformity decreases with size | Very High - 5-6 GPa pressure maintenance |

| CVD - Commercial Range | 1-20 carats (optimal production) | 2-4 weeks for 10-20 carat stones | Minimal at commercial sizes | Excellent - controlled environment | Low to Moderate |

| HPHT - Commercial Range | 1-15 carats (optimal production) | 3-7 days for 10-15 carat stones | Equipment scaling becomes challenging above 15ct | Good - proven process reliability | High - significant pressure requirements |

| CVD - Theoretical Limit | No theoretical size limit | 6+ months for 200+ carat stones | Extended growth periods increase defect probability | Decreases with extreme sizes | Exponentially increases with size |

| HPHT - Physical Limit | 50 carats (theoretical maximum) | 14-21 days for theoretical maximum | Press technology and uniform heating constraints | Poor at maximum theoretical sizes | Extreme - may exceed equipment capabilities |

CVD circumvents pressure limitations through plasma-activated chemical reactions at much lower pressures. Time becomes the primary limitation rather than physical constraints. The trade-off involves speed versus potential size – HPHT produces diamonds faster but hits size ceilings sooner.

Why Lab Diamonds Exceed Natural Size Limits

Lab diamonds surpass natural limitations by eliminating geological variables that constrain natural formation. Natural diamonds form under conditions that fluctuate over geological timescales. Temperature variations, pressure changes, and carbon source depletion naturally limit growth.

The largest natural diamond, the Cullinan, weighed 3,106 carats in rough form but was extraordinarily rare. Such discoveries occur maybe once per century. Lab growth can produce similar sizes on demand, limited only by production time and equipment capabilities.

"While many focus on the impressive size capabilities of CVD processes, its crucial to understand the nuanced balance between growing time and crystal integrity. For instance, extending the growth cycle to produce a 155-carat lab diamond introduces complexities such as maintaining plasma stability and managing energy consumption efficiently. These factors are pivotal in ensuring that the end product not only meets size expectations but also maintains the high-quality standards necessary for luxury applications. This insight underscores the technological marvel and the sophisticated control required in synthetic diamond production, setting a benchmark in the gemological industry."

Natural formation faces constant interruption from geological events – magma movement, temperature fluctuations, and chemical composition changes. Lab environments eliminate these variables completely. However, the time and energy required for massive stones may not justify the investment unless specific demand exists.

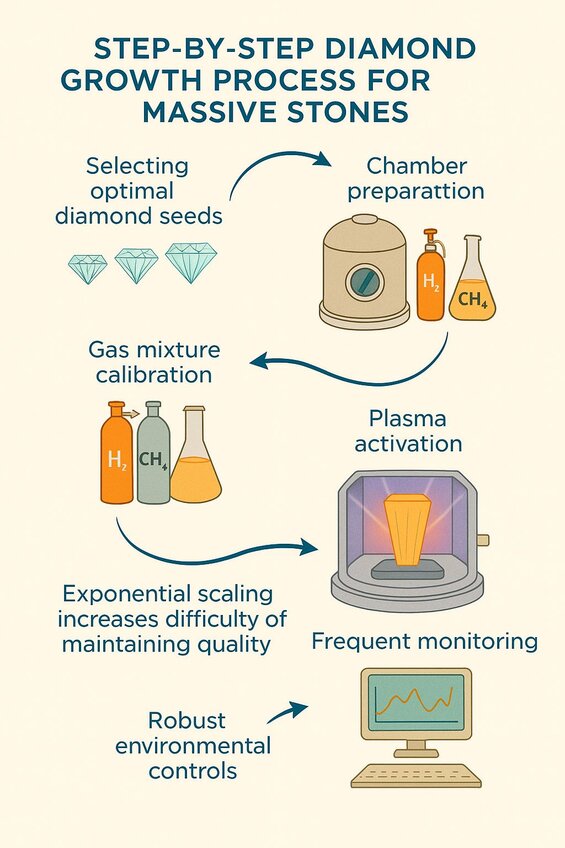

Step-by-Step Diamond Growth Process for Massive Stones

Creating large lab diamonds requires precise orchestration over extended periods. The foundation begins with selecting optimal diamond seeds – typically high-quality HPHT diamonds serving as crystal templates. Chamber preparation, gas mixture calibration, and plasma activation must maintain stability for months.

The process scales exponentially rather than linearly. A 1-carat diamond might require 2-4 weeks of growth. A 10-carat stone could need 3-4 months. Truly massive stones like the 155-carat record holder require 5-6 months of continuous operation.

Quality maintenance becomes increasingly challenging across longer cycles. Larger diamonds accumulate more opportunities for defects simply due to extended exposure times. This necessitates frequent monitoring, higher purity gas supplies, and robust environmental controls.

Our production experience reveals that the commercial sweet spot typically falls between 1-5 carats. Quality control remains manageable and production times stay economically justifiable.

Diamond Seed Technology for Growing Large Stones

Diamond seed selection becomes critical since any imperfections propagate throughout the crystal structure. Type IIA HPHT seeds work best for massive stones because they provide the purest foundation, though they cost significantly more than standard seeds.

For stones exceeding 10 carats, manufacturers typically use larger seed crystals – often 5-10mm squares rather than 3-5mm seeds. Seed preparation involves laser cutting to exact specifications, followed by acid cleaning to remove surface contaminants that could affect growth.

The challenge lies in balancing seed size with growth rate. Larger seeds accelerate initial growth but require more expensive materials. Smaller seeds cost less but extend already lengthy timelines. Most manufacturers use medium-sized seeds as the optimal compromise.

Premium Seed Investment ROI Analysis

A commercial lab-grown diamond manufacturer was producing 15-carat stones using standard Type I HPHT seeds costing $800 per production run. While the diamonds achieved decent clarity grades (VS1-VS2), they contained nitrogen inclusions that limited final market value to approximately $45,000 per stone. The 4-month CVD growth cycles were generating acceptable profits, but the company identified potential for premium market positioning.

The manufacturer invested $5,000 in ultra-pure Type IIA HPHT seeds (6mm squares) for their next 15-carat production cycle. These premium seeds contained less than 1ppm nitrogen content and underwent laser-precision cutting plus multi-stage acid cleaning. The higher seed quality required identical growth parameters but provided a purer crystal foundation throughout the extended CVD process.

The resulting 15-carat diamond achieved VVS1 clarity with D-color grading, commanding a final market value of $70,000 – exactly $25,000 higher than standard seed production. The $4,200 net additional profit represented 84% ROI on the premium seed investment. Most significantly, the success rate for achieving top clarity grades increased from 60% to 95% when using Type IIA seeds, making the premium investment economically justified for stones exceeding 10 carats.

Seed quality directly correlates with final diamond grade. CVD growth amplifies existing imperfections, so producers targeting large, high-quality stones must invest in premium seed materials.

Chemical Vapor Deposition Process Duration Factors

CVD duration depends on multiple interconnected variables including growth rate, target size, and quality requirements. Standard growth rates range from 10-30 micrometers per hour. A 5-carat finished diamond requires roughly 2000-3000 hours of continuous growth time.

Temperature consistency becomes increasingly critical in extended cycles. Fluctuations of even 20-30°C can create color variations or crystal defects in large stones. Methane concentration must remain within 1-5% of the gas mixture throughout the entire period.

Gas purity requirements escalate dramatically for large stones. Contamination levels acceptable for small diamonds become problematic when accumulated over months of growth. This necessitates higher-grade gas supplies and enhanced monitoring protocols.

Power consumption scales significantly with both size and duration. Large diamond production requires 6-12 months of continuous plasma operation at 3-8kW power levels.

HPHT Extreme Pressure Application Methods

HPHT production of large diamonds requires specialized press technology capable of generating uniform pressures across larger volumes. Standard belt presses max out around 200mm diameter chambers, while larger diamonds need cubic presses with enhanced distribution capabilities.

Temperature control becomes exponentially more challenging with size. Large chambers require more power to reach target temperatures of 1400-1600°C. Maintaining thermal uniformity across bigger volumes demands sophisticated heating element design.

The growth cycle for large HPHT diamonds typically lasts 1-4 weeks depending on target size – significantly faster than CVD but still requiring precise parameter control. Pressure fluctuations can create internal stress leading to cracking or clarity issues.

Our HPHT capabilities include both belt and cubic press systems, allowing us to optimize production methods based on target size and quality specifications.

Quality Standards for Large Lab Grown Diamond Investment

Large lab diamonds face intensified quality challenges that don't affect smaller stones. Extended growth periods create more opportunities for contamination, crystal defects, and color variations to develop. Quality control becomes exponentially more complex.

Type IIA classification becomes the gold standard since nitrogen contamination acceptable in smaller stones becomes visually apparent in larger sizes. Clarity requirements also intensify – inclusions barely visible in 1-carat stones become prominent features in 10+ carat diamonds.

Color consistency presents unique challenges. What appears uniform in smaller diamonds can reveal subtle gradations in larger sizes under different lighting conditions. This requires sophisticated color control during production and rigorous grading standards.

| Quality Parameter | 1-Carat Investment Grade | 5-Carat Investment Grade | 10+ Carat Investment Grade |

|---|---|---|---|

| Clarity Standard | VVS2 or higher | VVS1 or higher | IF (Internally Flawless) required |

| Color Grade | D-F (Near Colorless acceptable) | D-E (Colorless required) | D only (Exceptional colorless) |

| Cut Grade | Excellent or Very Good | Excellent only | Excellent with perfect symmetry |

| Type Classification | Type IIa preferred | Type IIa required | Type IIa mandatory |

| Fluorescence | None to Faint | None preferred | None required |

| Growth Defect Tolerance | Minor acceptable | Minimal only | Zero tolerance |

| Certification Requirements | IGI or GIA standard | GIA or GCAL preferred | Dual certification required |

| Quality Control Inspections | 2-3 checkpoints | 4-5 checkpoints | 6+ checkpoints |

Our quality control protocols include multiple intermediate inspections during growth, allowing us to identify potential issues before they compromise the entire production cycle.

The certification process becomes more complex for large diamonds. Standard gemological equipment may not accommodate oversized stones, requiring specialized testing procedures. IGI, GIA, and GCAL have developed specific protocols, but certification timelines can extend several weeks.

Cutting challenges multiply with size since larger rough diamonds offer more options but present greater risks. A mistake during cutting represents significantly larger financial loss. This typically requires master cutters with specific experience in large stone preparation.

Choosing Your Ideal Lab Diamond Size Within Budget

Size selection should balance visual impact, budget constraints, and practical considerations rather than simply maximizing carat weight. The relationship between size and visual impact isn't linear – a 2-carat diamond doesn't appear twice as large as a 1-carat stone.

The practical sweet spot falls between 1-3 carats where quality control remains optimal and production costs stay reasonable. Visual impact satisfies most preferences while maintaining practical budgets. Beyond 3 carats, cost increases accelerate while visual improvements become more subtle.

"While many assume a larger diamond always results in greater visual impact, its important to understand that beyond a certain size, the increase in perceived size diminishes significantly. For instance, the perceptual difference in size between a 1-carat and a 2-carat diamond is less dramatic than many expect, due to the non-linear scaling of a diamonds dimensions. This insight is crucial for making informed decisions that align both with budget and aesthetic desires, ensuring customers receive the best value without compromising on beauty."

Setting requirements become important with size. Diamonds exceeding 3-4 carats may require custom mounting solutions and enhanced security features. Physical weight also affects wearability for daily use jewelry.

Our client consultation experience shows that most end consumers gravitate toward 1.5-2.5 carat sizes when they understand the quality and value advantages in that range.

Budget allocation should consider total ownership cost, not just purchase price. Large diamonds require expensive settings, specialized insurance coverage, and potentially more frequent maintenance.

The flexibility advantage becomes most apparent in the 2-5 carat range where natural diamond costs become prohibitive. This represents the optimal zone for maximizing both visual impact and value advantages.

Cost Analysis for Large Lab Grown Diamond Investment

Pricing for large lab diamonds doesn't follow linear scaling patterns. While small lab diamonds might cost $800-1200 per carat, large diamonds often see per-carat prices decrease due to production economies, even though total investment costs increase substantially.

The cost advantage compared to natural diamonds becomes most pronounced in larger sizes. A 5-carat natural diamond might cost $100,000-200,000, while an equivalent lab stone could range from $15,000-40,000. These savings represent 70-85% reductions that actually increase with size.

8-Carat Diamond Investment Comparison

A client sought an exceptional 8-carat, D-color, VS1 clarity diamond for a milestone anniversary piece. Natural diamond quotes from three certified dealers ranged from $320,000-$380,000 for the stone alone, with additional costs of $8,500 for GIA certification, $15,000 for platinum setting with accent stones, and $4,200 annual insurance premiums (1.2% of appraised value).

We sourced an identical 8-carat lab-grown diamond (D-color, VS1, excellent cut) directly from our manufacturing partner for $48,000. Additional costs included $1,200 for IGI certification with laser inscription, $15,000 for the same platinum setting design, and $780 annual insurance premiums (1.2% of $65,000 appraised value).

Total first-year investment: $64,200 lab-grown versus $347,700 natural—a savings of $283,500 (81.5% reduction). Over 10 years, insurance savings alone total $34,200. The client allocated $180,000 of the savings toward matching lab-grown diamond earrings and a tennis bracelet, creating a complete set for less than the cost of the single natural stone.

Production economics favor certain size ranges. The 1-3 carat range offers optimal cost efficiency since production times remain manageable while providing significant size impact. Stones exceeding 5 carats require specialized approaches that can increase per-carat costs.

Our direct manufacturer pricing eliminates retail markups that can add 100-300% to final costs, providing access to large diamonds at true production costs plus reasonable margins.

Quality premiums escalate with size since maintaining high grades becomes more challenging in extended production cycles. A flawless 10-carat lab diamond commands significantly higher premiums than a flawless 1-carat stone, not just due to size but because achieving that clarity level requires exceptional production control.

Investment considerations should account for complete cost structure including certification, setting, insurance, and customization requirements. The financing implications may favor lab options since lower absolute costs make impressive sizes accessible.

Access Record-Breaking Sizes With Proven Production Mastery

Lab grown diamonds eliminate the geological lottery that limits natural stone availability. Whether you're seeking a 5-carat statement piece or exploring truly massive specimens, our direct manufacturing capabilities provide access to sizes that would cost 10x more in natural alternatives. Quality control, production timelines, and certification processes all favor the lab approach for large diamonds.

Secure Your Large Lab Diamond Consultation Today

Don't let size limitations constrain your diamond dreams. Contact Labrilliante's production specialists to discuss your large diamond requirements and explore what's possible with cutting-edge CVD and HPHT technology. Your extraordinary diamond awaits.

Frequently Asked Questions

The current world record is 155 carats, produced using CVD technology over approximately 150 days of continuous growth. This massive diamond required precise temperature control at 800-900°C and careful methane concentration regulation throughout the entire 5-month production cycle.

CVD technology can theoretically scale infinitely since it relies on continuous gas deposition rather than pressure constraints, with the largest CVD diamonds exceeding 150 carats. HPHT production maxes out around 35 carats due to physical press limitations and the difficulty of maintaining uniform pressure distribution of 5-6 GPa across larger growth chambers.

Interestingly, large lab diamonds often have lower per-carat costs due to production economies, even though total investment increases substantially. While small lab diamonds cost $800-1200 per carat, larger stones can be more cost-efficient, with the savings versus natural diamonds actually improving to 70-85% reductions in larger sizes.

Extended growth periods create more opportunities for contamination, crystal defects, and color variations to develop in large diamonds. Type IIA classification becomes essential since nitrogen contamination acceptable in smaller stones becomes visually apparent in larger sizes, and clarity requirements intensify as inclusions barely visible in 1-carat stones become prominent in 10+ carat diamonds.

Large lab diamonds offer better cost advantages compared to their natural counterparts, with savings that actually increase with size, but they face limited resale markets outside specialized collectors. The article suggests most commercial demand centers around 1-5 carat stones, making this range potentially more liquid for future resale than truly massive specimens.

Production failures in large diamonds represent total loss of months of investment, with many large diamond attempts failing completely due to the exponential increase in defect probability over extended growth periods. This creates massive opportunity costs and ties up expensive equipment that could have produced multiple smaller, more marketable diamonds during the same timeframe.

The practical sweet spot falls between 1-3 carats where quality control remains optimal, production costs stay reasonable, and visual impact satisfies most preferences. Beyond 3 carats, cost increases accelerate while visual improvements become more subtle, and the relationship between size and visual impact isn't linear.

Large diamonds require expensive custom settings, specialized insurance coverage with dramatically higher costs, and potentially more frequent maintenance than smaller stones. You should also factor in longer certification timelines, master cutter fees for proper preparation, and the physical weight considerations that may affect daily wearability.