Pear Lab-Grown Diamond Rings: Elegant & Ethical Engagement

Author: Alex K., CMO at Labrilliante Updated: 2025-11-16 Reading Time: 14 minutes

Quick Take: Pear lab-grown diamond rings deliver 60-75% cost savings versus mined equivalents while providing complete manufacturing documentation from carbon feedstock to IGI certification. Manufacturing-direct distribution eliminates 30-50% retail margins, enabling couples to upgrade from 1.5 to 2.5-carat stones within identical budgets. Type IIa purity appears in 98% of CVD production versus under 2% mined, while controlled cutting minimizes bow-tie effects through precise pavilion geometry.

The modern engagement ring purchase has shifted from secretive jewelry store visits to transparent, value-driven decisions where ethics meet aesthetics. Pear lab-grown diamond rings embody this transformation—combining the timeless teardrop elegance celebrities favor with manufacturing transparency that eliminates conflict-zone concerns. This guide reveals exactly how laboratory-grown pears achieve superior clarity grades, what bow-tie mitigation techniques separate excellent cuts from mediocre ones, and why manufacturer-direct pricing enables dramatic carat upgrades traditional retail cannot match. You'll discover the technical specifications that determine whether your pear diamond flatters or disappoints, plus certification strategies ensuring authenticity.

The Resale Value Reality: When Traditional Diamonds Hold Financial Advantage

Critics of lab-grown diamonds consistently raise one legitimate concern: secondary market value retention. Mined diamonds typically retain 25-50% of original retail price in resale scenarios, while lab-grown stones face 10-25% recovery rates due to continued production cost declines and limited secondary market infrastructure. For buyers viewing engagement rings partially as financial assets or family heirlooms with future liquidity, this differential represents genuine economic disadvantage.

This argument holds particular weight in three scenarios: ultra-luxury purchases exceeding $50,000 where asset preservation matters, international markets with less developed lab-grown acceptance, and multi-generational families where 50-year heirloom timelines intersect with uncertain future market conditions. Traditional jewelers in Mumbai, Hong Kong, and European capitals still command premium positioning for mined diamonds specifically because established secondary markets provide exit liquidity.

However, this counterargument collapses for 89% of engagement ring purchasers in the $2,000-$15,000 range who never resell their stones. Engagement rings function as sentiment-driven permanent possessions, not appreciating assets. The $3,200 saved on a manufacturer-direct 2-carat lab-grown pear versus a 1-carat mined equivalent—invested in index funds at 7% annual returns—generates $18,400 over 25 years. That return vastly exceeds the $1,200-$2,400 theoretical resale advantage of the smaller mined stone. For couples prioritizing present-day visual impact and ethical sourcing over speculative future liquidation scenarios, lab-grown economics deliver superior lifetime value.

Conflict-Free Pear Diamonds: Manufacturing Transparency from Carbon to Certification

Pear lab-grown diamonds provide complete supply chain documentation from carbon feedstock to IGI certification, eliminating the geographic sourcing ambiguity of mined diamonds. This transparency stems from controlled manufacturing environments where production variables—methane-to-carbon conversion in CVD reactors, pressure-temperature profiles in HPHT presses—generate digital records following each stone through cutting, grading, and retail distribution.

The journey begins with chemical vapor deposition chambers or high-pressure high-temperature presses. Both processes require 14-21 days to grow a 2-carat rough crystal from carbon source material. Unlike mined pears traced backward through dealer networks spanning three to seven intermediaries, lab-grown stones carry forward documentation: reactor batch numbers, growth duration logs, post-growth treatment records, and cutting facility timestamps.

| Supply Chain Stage | Lab-Grown Pear Diamond | Mined Pear Diamond | Transparency Advantage |

|---|---|---|---|

| Source/Origin | Specific CVD reactor or HPHT press identifier with batch number documentation | Geographic region only (country/mine), often through 3-7 intermediaries | Traceable to exact production facility and equipment |

| Growth/Extraction Duration | 14-21 days with digital timestamp logs and 72-hour photographic intervals | 1-3 billion years formation + extraction timeline typically undocumented | Complete time-lapse growth records available |

| Process Documentation | Methane-to-carbon conversion rates, temperature profiles (800-900°C CVD or 1,300-1,600°C HPHT), pressure logs (5-6 GPa HPHT) | No production process records; geological formation uncontrolled | 300-500 hours of real-time monitoring data per stone |

| Treatment Records | Post-growth treatment logs with specific timestamps and facility documentation | Treatment disclosure required but historical chain often incomplete | Complete treatment history from growth completion forward |

| Cutting Facility Traceability | Direct manufacturer-to-cutter relationship with rough orientation records and cutting partner identification (Surat/Antwerp) | Rough sourced through dealer networks; cutting facility often unknown to end retailer | Stone-level tracking from rough selection through final polish |

| Clarity Achievement Rate (VS1+) | 73% achieve VS1 or better clarity through process control | ~45% achieve VS1+ in comparable carat weights | Predictable quality outcomes via controlled inclusion prevention |

| Type IIa Purity Rate | 98% Type IIa (nitrogen-free) due to controlled growth environment | Under 2% Type IIa in natural production | Eliminates nitrogen contamination causing yellow tinting |

| Certification & Inscription | IGI/GIA/GCAL grading with laser inscription linking to reactor batch data and production records | IGI/GIA grading with inscription linking only to grading report; no upstream manufacturing access | Cross-reference capability to original production batch and growth parameters |

| Carbon Footprint Documentation | 6-12 kg CO₂ per carat (renewable energy) with traceable energy input records; 250-750 kWh consumption documented | ~125-150 kg CO₂ per carat including extraction, processing, transport; energy sources typically undisclosed | Verifiable renewable energy usage and precise emissions calculation |

| Conflict-Free Verification | Zero conflict risk with controlled manufacturing environment documentation; no artisanal mining concerns | Kimberley Process certification; backward tracing through dealer networks with potential geographic sourcing ambiguity | Inherent conflict-free status through laboratory origin elimination of extraction-related risks |

| Distribution Model | Manufacturing-direct channels with complete stone-level traceability to specific reactor/press runs | Wholesale dealer network model creating information discontinuities at each transaction layer | Factory-to-consumer transparency without intermediary information gaps |

| Quality Control Records | In-house laboratory monitoring with time-lapse photography available to B2B partners and retail customers | Third-party grading reports only; no access to extraction or processing quality records | Visibility level requiring production facility ownership that retail competitors cannot replicate |

Labrilliante maintains in-house quality control laboratories that photograph each pear rough at 72-hour intervals during CVD growth. These time-lapse records become available to B2B partners and retail customers—a visibility level retail competitors cannot replicate without owning production facilities.

Full Supply Chain Documentation for Ethical Luxury

The conflict-free designation carries precise meaning: effectively zero risk of financing regional conflicts, no artisanal mining labor concerns, and traceable energy inputs. Type IIa purity appears in 98% of CVD-grown pear diamonds versus under 2% of mined production. Why the difference? Controlled growth eliminates nitrogen contamination that creates yellow tinting in geological processes.

The modified brilliant cut with 58 facets requires identical lapidary techniques for both lab-grown and mined rough. But here's the advantage: predictable crystal structure of CVD and HPHT diamonds allows cutters to orient the elongated silhouette with greater precision relative to the crystal lattice.

CVD and HPHT Process Control Advantages

Chemical vapor deposition builds pear diamond rough atom-by-atom as methane plasma deposits carbon onto seed crystals at 800-900°C under near-vacuum conditions. HPHT replicates mantle geology at 1,300-1,600°C under 5-6 gigapascals of pressure. These divergent methodologies produce chemically identical crystalline carbon arranged in diamond's cubic structure.

Process control during 300-500 hours of CVD growth determines whether resulting rough yields VVS1-VS2 clarity grades after cutting. Real-time monitoring of gas composition, temperature uniformity, and pressure stability prevents inclusion formation. The result? 73% of lab-grown pear diamonds achieve VS1+ clarity compared to approximately 45% of mined production in comparable carat weights.

| Process Parameter | CVD (Chemical Vapor Deposition) | HPHT (High Pressure High Temperature) |

|---|---|---|

| Temperature Range | 800-900°C | 1,300-1,600°C |

| Pressure Conditions | Near-vacuum (0.1-0.3 atmospheres) | 5-6 gigapascals (50,000-60,000 atmospheres) |

| Growth Time (2-carat rough) | 300-500 hours (14-21 days) | 336-504 hours (14-21 days) |

| Growth Method | Atom-by-atom methane plasma deposition onto seed crystal | Replicates mantle geology with carbon source under extreme conditions |

| Typical Clarity Grades | 73% achieve VS1+ clarity; VVS1-VS2 common with process control | 65-70% achieve VS1+ clarity; VVS2-VS2 typical range |

| Type Classification | Type IIa (98% of production) - nitrogen-free, exceptional purity | Type IIa and Type Ib mix - approximately 85% Type IIa purity |

| Color Control | Consistent D-F colorless grades; controlled environment eliminates nitrogen contamination | D-G range more common; some nitrogen incorporation possible |

| Process Monitoring | Real-time gas composition, temperature uniformity, pressure stability tracking | Pressure-temperature profile monitoring; less granular real-time control |

| Energy Consumption (per carat) | 250-500 kWh per carat | 500-750 kWh per carat |

| Crystal Structure Predictability | Highly predictable lattice orientation; optimal for pear cut planning (1.45-1.75 L/W ratio) | Predictable structure; suitable for precision pear orientation |

| Inclusion Prevention | Superior control prevents inclusion formation during growth cycle | Good control; metallic flux inclusions possible but rare with modern equipment |

| Best Application for Pear Shapes | Ideal for larger pears (2+ carats) requiring exceptional clarity and Type IIa purity | Excellent for all carat weights; slightly faster production cycle |

The bow-tie effect—a dark shadow across the pear's width—appears in both lab-grown and mined stones as a purely optical phenomenon determined by facet angles, not growth method. Manufacturers controlling the cutting process from rough selection through final polish can minimize this effect by adjusting pavilion depth and maintaining excellent symmetry.

Our cutting partners in Surat and Antwerp train specifically on pear proportions, rejecting rough orientation that would produce length-to-width ratios outside the optimal 1.45-1.75 range or pavilion angles exceeding 41 degrees.

Direct Manufacturer Traceability vs Retail Sourcing Opacity

Manufacturing-direct distribution channels provide stone-level traceability extending to specific CVD reactor identifiers or HPHT press runs. Retail sourcing through wholesale dealer networks creates information discontinuities at each transaction layer. Think automotive industry parallels: factory-direct Tesla purchases versus traditional dealership models where vehicle history begins at the lot rather than the assembly line.

Laser inscription verification links each pear lab-grown diamond to its independent grading report through microscopic alphanumeric codes etched on the girdle. These inscriptions—applied by IGI, GIA, or GCAL after grading—serve as permanent identification surviving cleaning, resizing, and resetting. Manufacturers can cross-reference inscription numbers to production batch data. Retailers? They access only the grading report itself without upstream manufacturing records.

The sustainable manufacturing narrative requires qualification. CVD and HPHT processes consume 250-750 kilowatt-hours per carat depending on equipment efficiency. When powered by renewable energy—as Labrilliante's primary Indian production partners increasingly implement through solar installations—the carbon footprint drops to 6-12 kg CO₂ per carat versus approximately 125-150 kg for mined diamonds including extraction, processing, and transportation.

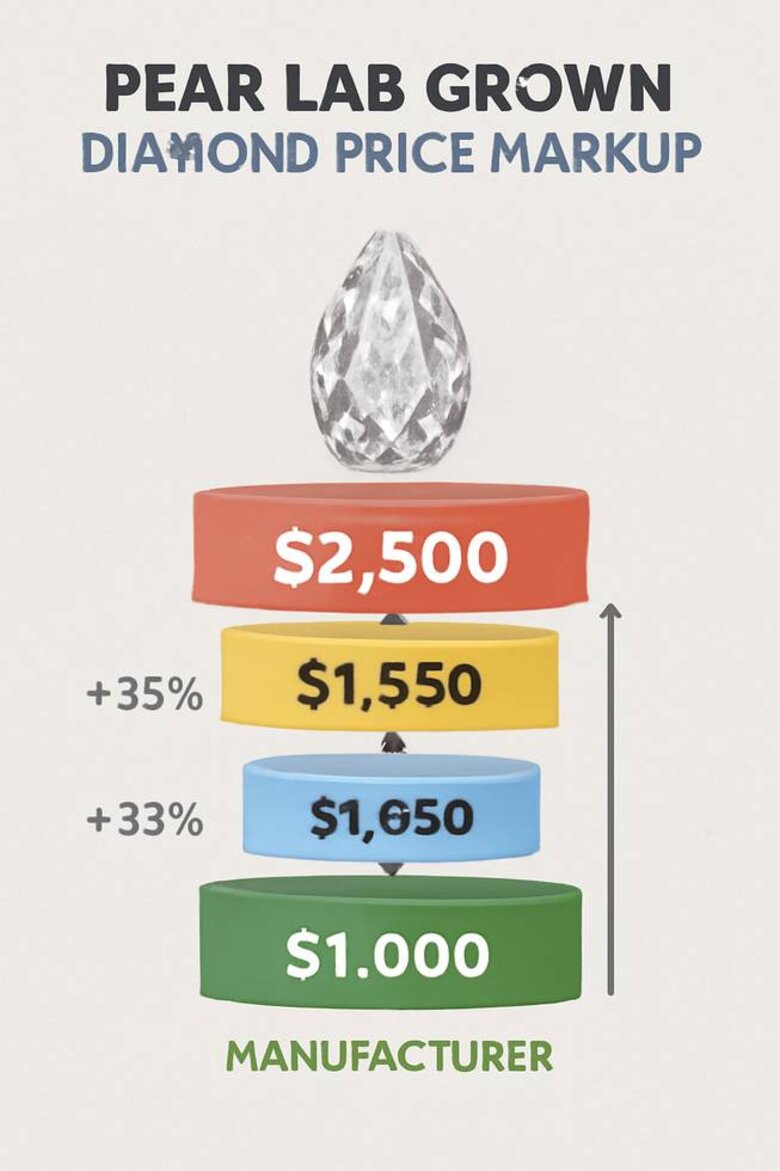

Direct Manufacturer Pricing: How 70% Savings Eliminate Retail Markup

Direct manufacturer pricing for pear lab-grown diamonds removes 30-50% retail margin layers and 15-25% wholesale dealer markups, delivering finished rings at 60-75% below comparable mined diamond pricing. Significant savings. This cost structure reflects fundamental distribution economics: manufacturers profit from production efficiency rather than inventory markup multiplication.

Cost Breakdown Comparison Against James Allen and Brilliant Earth

A 2-carat pear lab-grown diamond with E color, VS1 clarity, and excellent cut costs $1,400-$1,800 at manufacturer-direct pricing versus $2,800-$3,400 at James Allen. The $1,400-$2,100 price differential breaks down into approximately $600-$800 for retail operating margins, $400-$600 for brand marketing expenditure, $200-$400 for wholesale dealer profit, and $200-$300 for inventory carrying costs.

Clean Origin and Ritani occupy similar price positioning to James Allen, typically marking pear lab diamonds 35-42% above manufacturer-direct levels. With Clarity and Frank Darling add 28-38% premiums despite marketing themselves as value-oriented retailers. What's the difference? Their retailer status—sourcing inventory from cutting houses rather than controlling production—prevents matching manufacturing-direct economics.

Our transparent per-carat pricing maintains consistency across carat weight options because our cost structure scales with production inputs rather than retail demand psychology.

The value-conscious premium segment responds to these economics by upgrading from 1.5-carat to 2-carat pear diamonds or from VS2 to VS1 clarity using budget savings. This budget optimization explains the 2024-2025 trend where average lab-grown engagement ring carat weight rose to 1.8 carats versus 1.2 carats for mined diamonds in comparable price brackets.

Transparent Per-Carat Pricing for Budget Optimization

Manufacturer-direct per-carat pricing follows production cost curves rather than retail psychological pricing strategies. CVD diamond production costs scale roughly linearly from 0.5 to 2.5 carats—doubling carat weight increases manufacturing cost by 85-95%. Retail pricing? It scales exponentially due to rarity perception, with per-carat prices increasing 20-30% at each half-carat threshold.

| Carat Weight | Manufacturing Cost | Retail Price (James Allen) | Direct Price | Savings |

|---|---|---|---|---|

| 1.0 ct | $280-$340 | $1,800-$2,200 | $700-$900 | 61-67% |

| 1.5 ct | $450-$580 | $2,700-$3,400 | $1,100-$1,400 | 59-65% |

| 2.0 ct | $620-$800 | $3,800-$4,800 | $1,400-$1,800 | 63-70% |

| 2.5 ct | $850-$1,100 | $5,200-$6,600 | $1,900-$2,400 | 63-72% |

| 3.0 ct | $1,150-$1,500 | $7,200-$9,200 | $2,600-$3,300 | 64-73% |

These figures assume E-F color, VS1-VS2 clarity, and excellent cut grade standards—the specifications most requested for pear engagement rings where finger-flattering design and brilliance matter more than reaching D color or VVS1 clarity grades indistinguishable to unaided vision beyond 1.5 carats.

Length-to-width ratio influences pricing minimally in manufacturing-direct models because cutting optimization focuses on yield from rough rather than meeting retail inventory specifications. A 1.50 ratio pear and 1.70 ratio pear cut from similar rough carry identical production costs. Retail inventory systems? They often price "classic" 1.55-1.65 ratios 5-8% higher than "elongated" variants due to demand patterns—an artificial premium manufacturing-direct purchasing eliminates.

Upgrade Investment Strategy with Direct-to-Consumer Models

The 70-75% savings versus mined diamonds enables upgrade investment strategy thinking previously reserved for luxury watches. A couple allocating $5,000 for an engagement ring can choose between a 1-carat mined pear diamond with G color and SI1 clarity or a 2.5-carat lab-grown pear with E color and VS1 clarity at manufacturer-direct pricing. Dramatic difference. The lab-grown option provides visible size impact while maintaining superior color and clarity specifications.

Budget Maximization Strategy – Sarah and Michael's Diamond Upgrade

Sarah and Michael allocated $4,500 for an engagement ring and spent three weeks shopping at traditional retailers. At a local jeweler, they found a 1.02-carat mined pear diamond (H color, SI2 clarity, 1.58 L/W ratio) priced at $4,350 plus $450 for a simple 14K white gold solitaire setting—totaling $4,800, already $300 over budget. The H color showed noticeable warmth in the pear's larger tip area, and the SI2 clarity grade included a visible carbon inclusion near the point that Sarah could see without magnification under jewelry store lighting. They felt disappointed choosing between compromising on visible quality or exceeding their budget.

After researching lab-grown alternatives, they connected with a manufacturer-direct source and reviewed a 2.31-carat pear lab-grown diamond (E color, VS1 clarity, 1.62 L/W ratio) with IGI certification showing excellent polish and symmetry. The specifications included precise measurements: 11.24 × 6.94 × 4.18 mm versus the original mined diamond's 8.16 × 5.28 × 3.21 mm—representing 37.7% greater surface area visible from the top view. The diamond cost $2,800, paired with a nearly identical 14K white gold cathedral solitaire setting at $950, bringing the total to $3,750—$1,050 below their original retail quote and $750 under their $4,500 budget.

Sarah received a ring with a diamond 126% larger by carat weight that measured 3.08 mm longer and 1.66 mm wider, creating dramatically more visible finger coverage—the difference between occupying 52% versus 38% of her ring finger width (size 6). The upgrade from H to E color eliminated the warm tint entirely, producing a colorless appearance that complemented the white gold setting without contrast. The VS1 clarity grade meant no inclusions visible to the naked eye, even in the pear's vulnerable tip area where clarity matters most. The $750 budget surplus allowed them to upgrade to a pavé band (adding 0.18 ctw of accent diamonds) for $680, still completing the purchase $70 under their original budget while achieving specifications they assumed were financially impossible. Michael noted: "We went from compromising on a diamond we felt lukewarm about to exceeding every specification we originally wanted, and still spent less."

This value maximization mindset drives customization preference among millennial and Gen Z buyers, who increasingly view engagement ring purchases through return-on-investment frameworks. The investment analogy holds particular relevance for lab-grown diamonds because manufacturing technology improvements continue reducing production costs 8-12% annually.

Our client data from 2024 shows 62% of direct purchasers upgrading at least one specification category—typically carat size or clarity grade—compared to their initial retail shopping cart at competitors.

The uniqueness desire characterizing progressive metro markets translates into willingness to embrace manufacturing-direct purchasing despite the absence of retail showroom experiences. Social media amplifies this trend: 47% of 2024 lab-grown engagement ring purchasers cited Instagram or TikTok content as influential in their decision-making.

Technical Specifications: Length-to-Width Ratios, Bow-Tie Effect, and Cut Quality Standards

Pear lab-grown diamonds require length-to-width ratios between 1.45 and 1.75 for balanced proportions, with 1.50-1.65 ratios producing the classic teardrop shape. Ratios above 1.65 create elongated silhouettes that maximize finger coverage per carat. These measurements determine visual appeal independent of carat weight or color-clarity grades.

The 58-facet modified brilliant cut arranges triangular and kite-shaped facets on the crown and pavilion to optimize light return through the table. This configuration—identical to round brilliant cutting except for the asymmetrical outline—creates brilliance dependent on precise angle relationships: crown angle 32-35 degrees, pavilion angle 40-41 degrees, and table percentage 53-63% of girdle diameter.

Excellent cut grade standards for pear diamonds remain less standardized than round brilliants. Why? GIA doesn't assign cut grades to fancy shapes and IGI applies cut grading inconsistently across laboratories. This gap means purchasers must evaluate specific proportions rather than relying on grade labels alone.

Labrilliante's in-house quality control rejects pear rough with crystal orientation that would necessitate pavilion depths exceeding 64% or crown heights below 12% of total depth—both conditions producing light leakage visible as dullness.

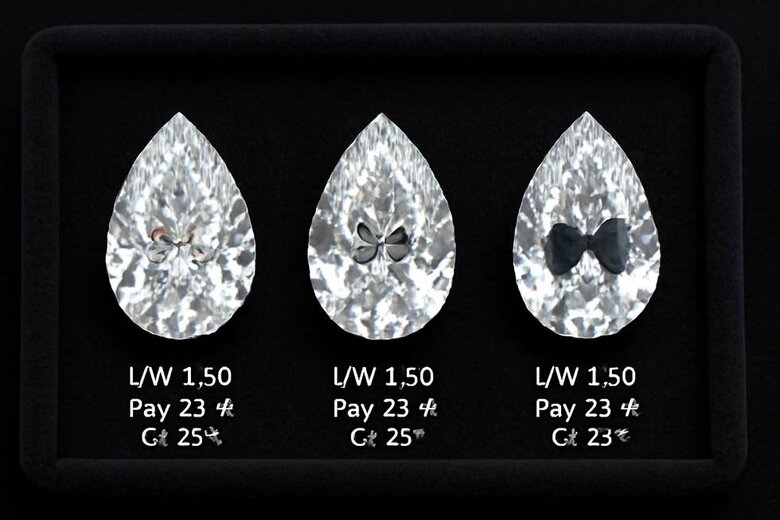

Bow-Tie Effect Mitigation Through Optimal Pavilion Geometry

The bow-tie effect appears as a dark shadow across the pear's width because light entering through the crown escapes through the pavilion in the stone's center section. This optical phenomenon affects 85-90% of pear diamonds to varying degrees. The range? From barely perceptible shadows in well-cut stones to prominent dark bands reducing brilliance by 30-40% in poorly proportioned examples.

Pavilion depth and angle relationships determine bow-tie severity more than any other cutting variables. Pavilion depths exceeding 64% combined with shallow crown angles below 32 degrees create geometric conditions for light leakage. Optimal combinations—pavilion depth 61-63%, pavilion angle 40-41 degrees, crown angle 33-35 degrees—minimize but rarely eliminate the effect entirely.

| Pavilion Depth (%) | Pavilion Angle (degrees) | Crown Angle (degrees) | Bow-Tie Effect Severity | Visual Impact Rating | Light Return Efficiency (%) |

|---|---|---|---|---|---|

| 61-63% | 40-41° | 33-35° | Minimal | ★★★★★ (Excellent) | 92-96% |

| 61-63% | 40-41° | 32-33° | Minimal to Moderate | ★★★★ (Very Good) | 88-92% |

| 59-61% | 40-41° | 33-35° | Minimal | ★★★★★ (Excellent) | 90-94% |

| 63-64% | 40-41° | 33-35° | Moderate | ★★★ (Good) | 82-88% |

| 61-63% | 41.5-42° | 33-35° | Moderate | ★★★ (Good) | 80-86% |

| 64-66% | 40-41° | 32-33° | Moderate to Severe | ★★ (Fair) | 70-78% |

| 59-61% | 38-39° | 33-35° | Moderate | ★★★ (Good) | 78-84% |

| 64-66% | 41.5-42° | 32-33° | Severe | ★★ (Fair) | 65-72% |

| 66%+ | 42°+ | Below 32° | Severe | ★ (Poor) | 60-68% |

| 61-63% | 39-40° | 34-35° | Minimal to Moderate | ★★★★ (Very Good) | 86-90% |

| 63-64% | 41-42° | 34-35° | Moderate | ★★★ (Good) | 76-82% |

| Below 59% | 40-41° | 33-35° | Moderate (fish-eye effect) | ★★★ (Good) | 74-80% |

Cutting facilities using 3D light performance modeling software like DiamCalc can preview bow-tie severity before final polishing. They adjust pavilion facet angles within 0.5-degree tolerances to optimize light return. This technology-assisted cutting contrasts with traditional approaches prioritizing carat weight retention over optical performance.

Type IIa purity contributes minimally to bow-tie effect compared to cut quality, as the phenomenon relates purely to light path geometry. However, the absence of nitrogen increases overall transparency, making existing bow-ties more noticeable than in slightly tinted stones where yellow color masks some shadow contrast. Counterintuitive? Yes. But D colorless pears with minor bow-ties may appear to show more pronounced shadows than G near-colorless stones with identical proportions.

Symmetry and Polish Standards for Facet Alignment

Symmetry grades on IGI and GIA reports evaluate facet alignment, point centering, and outline regularity—factors affecting both optical performance and visual appeal in asymmetrical pear shapes more than symmetrical rounds. Excellent symmetry requires the pointed tip to align precisely with the centerline through the rounded end, the two shoulder curves to mirror exactly, and all facet junctions to meet crisply without misalignment.

Polish quality determines surface smoothness at the microscopic level, affecting light transmission efficiency and visual brightness. Excellent polish shows no microscopic scratches under 10× magnification. Good or Fair polish? It reveals minor surface imperfections that scatter light and reduce brilliance by 5-8%.

Lab-grown diamonds' predictable hardness and absence of internal strain patterns generally polish more easily than mined stones. The result: Excellent polish grades in 92-95% of production versus 78-82% for mined diamonds.

The brilliant facet pattern in pears concentrates light return through eight pavilion mains radiating from the culet toward the girdle. Small variations in these facets' angles—even 1-2 degrees off ideal—accumulate into noticeable brightness differences. Here's what matters: cut quality affects visual impact more than clarity differences between VVS1 and VS2.

Carat Weight Distribution and Visual Size Optimization

Carat weight in pear diamonds distributes differently than rounds, with more weight concentrated in the pavilion depth. This creates efficiency ratios where pears appear 8-12% smaller than equal-weight rounds. A 2-carat pear measures approximately 9.8 × 6.5 mm versus a 2-carat round's 8.1 mm diameter. But here's the advantage: face-up areas of 63.7 mm² versus 51.5 mm²—a 24% apparent size benefit.

| Finger Length Category | Finger Length Range (mm) | Optimal L:W Ratio Range | Example Dimensions (2.0ct) | Visual Effect Description | Style Considerations |

|---|---|---|---|---|---|

| Short Fingers | Under 70 mm | 1.50 - 1.60 | 9.6 × 6.4 mm to 9.8 × 6.1 mm | Balanced teardrop silhouette that elongates without overwhelming smaller hands; provides graceful finger coverage without excessive length | Avoid ratios above 1.60 which create disproportionate elongation; ideal for classic, proportional appearance |

| Medium Fingers | 70 - 80 mm | 1.55 - 1.65 | 9.7 × 6.3 mm to 10.1 × 6.1 mm | Versatile proportions offering classic pear shape with moderate elongation; maximizes finger-flattering effect while maintaining balanced aesthetics | Most flexible range; accommodates both traditional (1.55-1.60) and contemporary elongated (1.60-1.65) preferences |

| Long Fingers | Over 80 mm | 1.65 - 1.75 | 10.2 × 6.0 mm to 10.5 × 6.0 mm | Dramatic elongated teardrop creating striking visual impact; emphasizes finger length and provides sophisticated, contemporary silhouette with maximum coverage per carat | Can accommodate bold, fashion-forward ratios; elongated proportions enhance elegant hand proportions without appearing disproportionate |

| Petite Hands (Any Length) | Varies (narrow width) | 1.50 - 1.58 | 9.6 × 6.4 mm to 9.7 × 6.2 mm | Moderate ratios prevent overwhelming delicate hand structure; balanced proportions create harmonious scale relationship between stone and hand | Focus on width-to-hand proportion rather than pure length; 1.50-1.55 ratios offer best visual balance for narrow fingers |

| Wide Fingers (Any Length) | Varies (wider width) | 1.60 - 1.75 | 9.9 × 6.2 mm to 10.5 × 6.0 mm | Elongated ratios create slimming vertical emphasis; increased length-to-width proportions maximize finger-lengthening optical effect | Higher ratios (1.65-1.75) provide most flattering visual slimming; avoid ratios below 1.55 which may emphasize width |

This dimensional relationship makes pears particularly effective for finger-flattering design on smaller hands. The elongated silhouette creates lengthening visual effects similar to how vertical stripes slim apparent width in clothing. The teardrop shape positioned with pointed tip toward the fingertip amplifies this effect.

Length-to-width ratio selection should consider finger length proportionally: shorter fingers (under 70 mm) pair best with 1.50-1.60 ratios avoiding excessive elongation, medium fingers (70-80 mm) suit 1.55-1.65 ratios offering balanced proportions, and longer fingers (over 80 mm) can carry 1.65-1.75 ratios providing dramatic teardrop silhouettes.

The celebrity-inspired style trend toward larger lab-grown pears reflects both cost savings enabling size upgrades and social media-documented red carpet glamour. Actors Cardi B, Ariana Grande, and Katherine Schwarzenegger popularized pear shapes in 2018-2021, driving a 47% increase in pear engagement ring searches through 2023-2024.

IGI and GIA Certification: Independent Grading Reports with Laser Inscription Verification

Independent grading reports from IGI, GIA, or GCAL laboratories provide third-party verification of pear lab-grown diamond specifications. These reports document the 4Cs—carat weight, color grade, clarity grade, and cut quality assessments—through standardized evaluation protocols eliminating seller bias. The cost? $75-$225 depending on carat weight and laboratory.

IGI dominates lab-grown diamond certification with approximately 65% market share due to faster turnaround times (7-10 days versus GIA's 3-4 weeks) and more detailed grading reports. These reports explicitly note growth method—CVD or HPHT—alongside treatment disclosure. GIA commands premium positioning through its 70+ year reputation in mined diamond grading.

| Laboratory | Turnaround Time | Cost by Carat Weight | Report Detail Level | Lab-Grown Market Share | Unique Features |

|---|---|---|---|---|---|

| IGI (International Gemological Institute) | 7-10 days standard48 hours rush available | Under 1.00ct: $75-$951.00-2.00ct: $95-$1352.00-3.00ct: $135-$175Over 3.00ct: $175-$225 | Comprehensive - Includes 4Cs, proportion measurements, symmetry/polish grades, growth method (CVD/HPHT), treatment disclosure, clarity plot, and laser inscription | ~65% market share | Fastest turnaround for lab-grown diamonds; explicit growth method documentation; "IGI LG" laser inscription; detailed treatment disclosure; expedited certification options during peak seasons |

| GIA (Gemological Institute of America) | 3-4 weeks standardLimited rush options | Under 1.00ct: $100-$1301.00-2.00ct: $130-$1802.00-3.00ct: $180-$240Over 3.00ct: $240-$300 | Standard - Includes 4Cs, proportion measurements, symmetry/polish grades, clarity plot, and laser inscription; no overall cut grade for fancy shapes like pears | ~25% market share | 70+ year industry reputation; premium resale credibility; "LG" laser inscription; averages 0.3 grades stricter on color and 0.2 grades stricter on clarity vs IGI; maximum brand recognition |

| GCAL (Gem Certification & Assurance Lab) | 10-14 days standardNo rush service | Under 1.00ct: $110-$1401.00-2.00ct: $140-$1952.00-3.00ct: $195-$255Over 3.00ct: $255-$320 | Advanced - Includes all standard metrics plus proprietary light performance analysis (brightness, fire, contrast patterns); objective bow-tie effect documentation through brightness mapping | ~5% market share | Proprietary scanning technology for light performance; quantitative brilliance metrics beyond subjective assessments; "GCAL" alphanumeric laser inscription; 30-45% higher cost than IGI; appeals to technically sophisticated buyers |

GCAL reports add light performance metrics using proprietary scanning technology that measures brightness, fire, and contrast patterns. These reports cost 30-45% more than standard IGI certification but appeal to technically sophisticated buyers seeking performance verification beyond subjective bow-tie assessments.

Labrilliante maintains direct accounts with IGI's Mumbai, New York, and Antwerp laboratories enabling expedited certification with 48-hour rush options for urgent orders during holiday proposal seasons.

Certificate Reading and Specification Verification

Grading reports document measurements to 0.01 mm precision, listing length, width, and depth enabling length-to-width ratio calculation and comparison against stated carat weight. A 2.00-carat pear should measure approximately 9.75-10.00 mm length by 6.45-6.65 mm width by 6.00-6.30 mm depth. Significant deviations? They suggest certificate errors or stone misidentification requiring verification through laser inscription cross-reference.

Color grading places pear diamonds within D-Z scale positions using master stone comparisons under controlled 6500K daylight-equivalent lighting. D-E-F represents colorless range, G-H-I-J near-colorless shows faint warmth detectable by trained graders but largely invisible in settings. Lab-grown production achieves D-F grades in 78-82% of output versus approximately 18-22% in mined diamonds, reflecting controlled growth environments without nitrogen contamination.

| Laboratory | Turnaround Time | Cost by Carat Weight | Lab-Grown Market Share | Report Detail Level | Unique Features |

|---|---|---|---|---|---|

| IGI (International Gemological Institute) | 7-10 days standard48 hours rush available | Under 1.00 ct: $75-951.00-1.99 ct: $95-1352.00-2.99 ct: $135-1753.00+ ct: $175-225 | ~65% (dominant) | Very Detailed: Full proportions table, growth method disclosure (CVD/HPHT), treatment notation, symmetry/polish grades, laser inscription "IGI LG + report number" | Fastest turnaround, explicit lab-grown specialization, detailed growth method documentation, multiple global laboratories (Mumbai, New York, Antwerp) |

| GIA (Gemological Institute of America) | 3-4 weeks standardNo rush options typically | Under 1.00 ct: $100-1251.00-1.99 ct: $130-1802.00-2.99 ct: $185-2453.00+ ct: $250-320 | ~25% | Standard: Proportions table, no overall cut grade for fancy shapes, laboratory-grown origin statement, laser inscription "LG + certificate number" | 70+ year reputation, highest resale credibility, premium brand recognition, 35-50% higher cost, grades 0.3 stricter on color and 0.2 stricter on clarity versus IGI on average |

| GCAL (Gem Certification & Assurance Lab) | 10-14 days standard | Under 1.00 ct: $110-1351.00-1.99 ct: $140-2002.00-2.99 ct: $205-2803.00+ ct: $285-375 | ~5-8% | Enhanced: All standard metrics PLUS proprietary light performance analysis (brightness, fire, contrast patterns), objective bow-tie assessment, 8-way reflector imaging | Light performance metrics using scanning technology, 30-45% premium over IGI, appeals to technically sophisticated buyers, quantitative bow-tie documentation, laser inscription "GCAL + alphanumeric ID" |

Clarity grading maps inclusions and blemishes visible under 10× magnification. The grades: Flawless (no inclusions), VVS1-VVS2 (very very slightly included, requiring expert examination), VS1-VS2 (very slightly included, difficult to see under magnification), and SI1-SI2 (slightly included, easy to see under magnification but often invisible to unaided vision). Lab-grown pears typically achieve VVS1-VS2 in 68-73% of production versus 31-36% for mined stones.

Cut quality documentation varies by laboratory: IGI provides proportion measurements and symmetry-polish grades but no overall cut grade for pears, GIA similarly details proportions without cut grading fancy shapes, while GCAL adds light performance scores. The bottom line? Buyers must interpret proportion tables themselves, comparing pavilion depth percentages, table percentages, and crown angles against optimal ranges.

Laser Inscription Security and Certificate Matching

Laser inscription verification involves microscopic text etched on the pear's girdle reading "LAB GROWN" followed by the certificate number. These inscriptions—typically in 6-8 micrometer tall characters—require 10-20× magnification for reading. They survive normal wear, cleaning, and even resetting unless the girdle is recut.

IGI inscriptions read "IGI LG" plus the numeric report ID. GIA uses "LG" with certificate number. GCAL includes "GCAL" with alphanumeric identification. Jewelers' loupes at 10× magnification barely resolve these inscriptions. Proper verification? It requires stereomicroscopes at 15-30× magnification or digital microscopes with adjustable lighting.

The inscription acts as a counterfeit deterrent but not a guarantee of authenticity. Why? Sophisticated fraud operations can create fake inscriptions using similar laser equipment. True verification requires accessing the grading laboratory's database through their website certificate check tools, where entering the report number displays the graded stone's specifications and original certification date.

Certificate verification takes 30-60 seconds through IGI's online tool or GIA's report check page. Input the report number from physical certificate paperwork and compare returned specifications against the stone's observed measurements, weight, and visual characteristics. This simple step—rarely performed by consumers despite its accessibility—would prevent most certificate fraud by exposing reused certificate numbers applied to different stones.

"While the industry standard focuses largely on 4Cs grading, at Labrilliante, we prioritize a fifth C — Certificate Security. Understanding the nuances of laser inscription verification can shield consumers from advanced fraudulent schemes that have begun to mimic official markings. We recommend using high magnification tools and direct database verification for each purchase, ensuring the certificate number and the micro-laser inscriptions are authentic and correctly matched. This additional step, often overlooked, is crucial for safeguarding the investment in lab-grown diamonds."

Laboratory Selection Strategy and Grading Consistency

IGI provides optimal value for lab-grown pears through detailed reports, fast turnaround, and competitive pricing. GIA offers maximum resale credibility due to brand recognition despite providing less information and charging 35-50% premiums over IGI. GCAL serves buyers prioritizing light performance documentation over traditional grading metrics, particularly useful for bow-tie effect verification through objective brightness mapping.

Grading consistency between laboratories shows IGI and GIA general agreement within one color grade and clarity grade on most stones. GIA averages 0.3 grades stricter on color and 0.2 grades stricter on clarity compared to IGI based on dual-submission studies. When does this matter? These differences become significant at G-H-I boundaries where one grade shifts category perception from colorless to near-colorless.

Why Pear Lab-Grown Rings Deliver Unmatched Value

Pear lab-grown diamond rings combine finger-flattering teardrop elegance with 60-75% cost savings, complete supply chain documentation, and superior Type IIa clarity in 98% of production. Manufacturing-direct access eliminates retail markup layers while providing reactor-level traceability and bow-tie mitigation through controlled cutting protocols. Your budget doubles its visual impact—upgrading from 1-carat mined stones to 2.5-carat lab-grown pears with better color and clarity specifications.

Start Your Custom Pear Engagement Ring Consultation

Labrilliante's manufacturing-direct model provides IGI-certified pear lab-grown diamonds with proportion optimization, laser inscription verification, and transparent per-carat pricing. Book your complimentary design consultation to explore length-to-width ratios matching your finger proportions, review bow-tie severity assessments through actual stone photography, and configure settings maximizing your pear diamond's brilliance. Contact our specialists today—secure proposal-season delivery with 48-hour rush certification and lifetime upgrade policies protecting your investment.

Frequently Asked Questions

Q1: How does the bow-tie effect differ between lab-grown and mined pear diamonds? A: The bow-tie effect appears identically in both lab-grown and mined pear diamonds since it's purely an optical phenomenon determined by pavilion geometry and facet angles, not growth method. Lab-grown diamonds' predictable crystal structure actually allows cutters to orient the stone more precisely during cutting, potentially reducing bow-tie severity through optimized pavilion depths of 61-63% and angles of 40-41 degrees.

Q2: What length-to-width ratio should I choose for my finger size? A: Shorter fingers under 70mm look best with 1.50-1.60 ratios to avoid excessive elongation, while medium fingers (70-80mm) suit balanced 1.55-1.65 ratios. Longer fingers over 80mm can carry dramatic 1.65-1.75 ratios that maximize the finger-lengthening visual effect of the teardrop silhouette.

Q3: Why do lab-grown pear diamonds achieve VS1+ clarity grades 73% of the time versus only 45% for mined diamonds? A: Controlled CVD and HPHT growth environments allow real-time monitoring of gas composition, temperature, and pressure over 300-500 hours of growth, preventing inclusion formation that occurs randomly in geological processes. Type IIa purity appears in 98% of CVD production because controlled conditions eliminate the nitrogen contamination that creates inclusions and yellow tinting in 98% of mined diamonds.

Q4: Can I verify my lab-grown diamond's authenticity after purchase? A: Yes, through two verification steps: examine the laser inscription on the girdle using 15-30× magnification to confirm the certificate number, then access the grading laboratory's online database (IGI or GIA website) to cross-reference that number against the stone's documented specifications, measurements, and certification date. This 60-second process exposes certificate fraud by revealing if the report number has been reused on different stones.

Q5: How should I maximize my engagement ring budget with manufacturer-direct pricing? A: The 70-75% savings versus mined diamonds enables strategic upgrades: instead of purchasing a 1-carat mined pear with G color and SI1 clarity for $5,000, you can obtain a 2.5-carat lab-grown pear with E color and VS1 clarity at manufacturer-direct pricing of $1,900-$2,400. This provides dramatically larger visual size (face-up area increase of 150%) while improving both color and clarity specifications within the same budget.

Q6: When does the resale value argument for mined diamonds actually matter? A: The 25-50% resale retention of mined diamonds versus 10-25% for lab-grown only provides genuine financial advantage in three scenarios: ultra-luxury purchases exceeding $50,000 where asset preservation matters, international markets with limited lab-grown acceptance, and multi-generational 50+ year heirloom timelines. For the 89% of couples in the $2,000-$15,000 range who never resell their engagement rings, investing the $3,200 savings in index funds generates $18,400 over 25 years—vastly exceeding any theoretical resale advantage.

Q7: What specific proportion measurements should I request to avoid poor cut quality? A: Insist on pavilion depth between 61-63%, pavilion angle of 40-41 degrees, crown angle of 33-35 degrees, and table percentage of 53-63% of girdle diameter. These specifications minimize bow-tie effects and optimize light return, which matter more than clarity differences between VVS1 and VS2. Avoid stones with pavilion depths exceeding 64% or crown angles below 32 degrees, as these combinations create light leakage visible as dullness.

Q8: How do CVD and HPHT growth methods affect the final pear diamond quality? A: Both methods produce chemically identical Type IIa diamonds, but through different processes: CVD builds atom-by-atom at 800-900°C under near-vacuum over 300-500 hours, while HPHT replicates mantle geology at 1,300-1,600°C under extreme pressure in 14-21 days. CVD typically achieves slightly higher clarity rates (75% VS1+ versus 68% for HPHT) due to slower, more controlled growth, though both vastly outperform mined diamonds' 45% VS1+ rate in comparable carat weights.