Bezel Set Lab-Grown Diamond Wedding Rings: Modern Elegance

Author: Alex K., CMO at Labrilliante Updated: 2025-12-15 Reading Time: 8 minutes

Bezel settings surround diamonds with protective metal rims—delivering 95% durability compared to prongs while costing 60-80% less with lab-grown stones. Healthcare professionals, fitness trainers, and minimalist brides choose this secure design for active lifestyles. Celebrity influence from royal weddings accelerates adoption. Metal options span platinum to gold, each requiring different maintenance over decades. Certification remains identical to traditional settings.

Wedding ring choices reveal more than aesthetic preference—they expose fundamental shifts in how couples define luxury, commitment, and daily practicality. Bezel set lab-grown diamond wedding rings answer a cultural demand for jewelry that protects what matters most while rejecting inflated markups and questionable ethics. This guide reveals why medical professionals, active brides, and conscious consumers choose bezel settings over traditional designs. You'll discover engineering advantages, cost breakdowns, celebrity influence, and styling insights that make these rings perfect for modern relationships built on transparency and lasting value.

When Traditional Prongs Actually Win: The Brilliance Trade-Off

Diamond purists argue bezel settings fundamentally compromise what makes diamonds desirable—maximum light performance and size appearance. They're not entirely wrong. Prong settings expose 85-90% of the diamond surface to light entry from multiple angles, while bezels restrict light access by covering the pavilion edges. For couples prioritizing fire, brilliance, and that iconic diamond sparkle above all else, this 10-15% light reduction matters significantly. Additionally, bezels can make smaller stones appear even smaller by hiding precious millimeters under metal, whereas prongs create visual lift that maximizes perceived size.

This critique holds particular weight for traditional shoppers purchasing smaller carat weights (under 0.75ct) where every millimeter of visible diamond counts. Classic solitaire prong settings became wedding standards precisely because they showcase stones to maximum effect—a valid priority for couples who view engagement rings primarily as visual statements rather than functional tools. The counterargument also applies when heirloom diamonds with exceptional cut grades enter the picture; covering precision faceting with metal bezels wastes the stone's optical engineering.

However, these scenarios represent specific buyer profiles, not universal truths. Many modern couples prioritize durability, ethical sourcing, and lifestyle compatibility, the bezel's protective engineering and contemporary aesthetic deliver superior long-term satisfaction. Lab-grown diamonds also shift this equation—when stones cost 60-80% less, buyers can afford larger carat weights that offset the bezel's size-minimizing effect while gaining security advantages prongs can't match. The choice isn't about right or wrong; it's about matching ring design to how you'll actually wear it over decades.

| Comparison Factor | Bezel Setting | Prong Setting |

|---|---|---|

| Light Performance | Reduced light return (metal rim blocks some side light) | 100% light return (maximum light entry from all angles) |

| Diamond Protection Level | Complete edge protection - metal fully encircles diamond, ideal for active lifestyles | Moderate protection - diamond edges exposed between prongs, risk of chipping |

| Maintenance Requirements | Low - metal rim holds stone securely, minimal prong checking needed | High - prongs require regular inspection every 6 months, retipping needed every 3-5 years |

| Aesthetic Style | Modern, sleek, streamlined - celebrity favorite (Meghan Markle, Jennifer Aniston) | Classic, traditional, maximum sparkle - timeless bridal look |

| Lifestyle Compatibility | Excellent for active lifestyles - no snags on clothing, gym-safe, low-profile design | Moderate - prongs can catch on fabrics, requires careful handling during activities |

| Perceived Diamond Size | Slightly smaller appearance - metal rim covers outer edge of diamond | Larger appearance - entire diamond visible, crown fully exposed |

| Metal Usage | Higher metal content - requires more gold/platinum for rim construction | Lower metal content - minimal metal used for prongs only |

| Lab-Grown Diamond Price Range (1-2ct) | $2,200-$4,500 (includes higher metal cost) | $1,800-$3,800 (less metal required) |

| Mined Diamond Price Range (1-2ct) | $16,000-$35,000 (includes higher metal cost) | $15,000-$32,000 (less metal required) |

| Best For | Healthcare workers, athletes, parents, minimalist style lovers, active professionals | Traditional brides, maximum brilliance seekers, office workers, formal occasions |

| Resizing Difficulty | Moderate to difficult - bezel requires careful reconstruction to maintain stone security | Easy - simple band adjustment without affecting stone setting |

| Durability Rating | Exceptional - exceptional stone security and longevity | 7.5/10 - dependent on prong maintenance and wear patterns |

*disclaimer: "Exact performance varies by specific ring design and diamond cut"

*disclaimer: "Exact performance varies by specific ring design and diamond cut"

Lab-Grown Diamonds Enable Celebrity-Style Accessibility

Lab-grown diamonds make celebrity-inspired bezel rings affordable for everyone. Mined diamond bezel rings cost $15,000-$50,000. Lab-grown alternatives with identical properties? Just $2,000-$8,000.

Same carbon crystal structure. Same hardness and brilliance. The formation process differs - billions of years underground versus weeks in controlled laboratories. The end result? Chemically identical diamonds.

CVD diamonds excel in bezel settings due to superior clarity grades and Type IIa purity. HPHT diamonds offer excellent color consistency. Perfect for matching multiple stones in complex bezel designs.

Your Love Story Deserves a Setting That Protects Forever

Bezel settings function as permanent diamond armor. The unbroken metal barrier shields the stone's vulnerable girdle edge from chips and impacts.

This makes perfect sense for active lifestyles. Physical demands, frequent handwashing, equipment handling - bezel settings handle it all. Your diamond stays secure while you live your life.

The Science of Stone Security

Three bezel variations serve different needs. Full bezels enclose the entire diamond perimeter for maximum protection. Partial bezels protect vulnerable areas while maintaining light exposure. Flush settings position diamonds level with surrounding metal for ultimate low profile comfort.

Here's the engineering reality: The metal rim must be thin enough to complement the diamond yet thick enough for daily wear. Platinum bezels offer superior durability and maintain appearance longer. Gold bezels provide warmth and traditional appeal but require more maintenance.

White gold bezels need periodic rhodium plating to stay bright. Platinum doesn't. Factor this into your long-term ownership costs.

| Bezel Metal Type | Initial Setting Cost (1ct Lab Diamond) | Maintenance Required | Maintenance Frequency | Cost Per Maintenance | 10-Year Maintenance Total | Total 10-Year Cost | Durability Rating |

|---|---|---|---|---|---|---|---|

| Platinum 950 | $1,850 | Professional cleaning and prong inspection | Every 18-24 months | $75 | $375 | $2,225 | 9.5/10 |

| 18K White Gold | $1,200 | Rhodium re-plating + cleaning | Every 12-18 months | $150 | $1,050 | $2,250 | 7.5/10 |

| 14K White Gold | $950 | Rhodium re-plating + cleaning | Every 10-14 months | $140 | $1,260 | $2,210 | 7/10 |

| 18K Yellow Gold | $1,200 | Professional cleaning and polish | Every 18-24 months | $85 | $425 | $1,625 | 8/10 |

| 14K Yellow Gold | $950 | Professional cleaning and polish | Every 18-24 months | $80 | $400 | $1,350 | 7.5/10 |

| 18K Rose Gold | $1,200 | Professional cleaning and polish | Every 18-24 months | $85 | $425 | $1,625 | 8/10 |

Emotional Resonance of Protective Settings

Modern couples view ring choices as relationship reflections. The bezel setting's protective nature creates a marriage metaphor. Surrounding and safeguarding what matters most.

This symbolism resonates strongly with couples prioritizing sustainable love stories. Healthcare workers, teachers, fitness professionals choose bezel settings for lifestyle compatibility, not just aesthetics. The lab-grown component adds intentional luxury that reflects conscious values.

Bottom line? Traditional solitaires maximize diamond visibility. Bezels prioritize longevity and daily wearability. Your choice reflects how you envision wearing rings over decades.

"While the bezel setting is renowned for its robust protection, it's lesser-known that the method of its construction can significantly affect the diamond's brilliance. A precisely engineered bezel setting, which ensures optimal light entry angles, can actually enhance the diamond's sparkle contrary to the common belief that it reduces brilliance. This balance between protection and aesthetics is critical, especially in settings involving high-performance metals like platinum, which reflect light internally due to their denser molecular structure."

Why Active Brides Are Choosing Sleek Bezel Security Over Prongs

Healthcare professionals and fitness enthusiasts increasingly select bezel settings for superior practicality. The low profile prevents snagging on gloves, equipment, or fabrics.

No prong loosening concerns either. Bezel settings distribute pressure evenly around your finger, eliminating pressure points that plague traditional settings.

Lifestyle Compatibility Analysis

The minimalist bride trend of 2025 reflects intentional consumption and streamlined aesthetics. Modern elegance emphasizes clean lines and understated luxury over elaborate ornamentation.

Bezel settings align perfectly with this movement. Sophisticated simplicity that complements contemporary fashion and lifestyle choices.

What about professional environments? Medical professionals frequently sanitize hands and wear protective gloves - activities that can loosen prongs over time. Teachers and childcare workers face similar challenges with frequent handwashing and potential equipment contact.

The psychological comfort of secure diamonds allows focus on professional responsibilities without jewelry anxiety.

Laboratory certification from IGI, GIA, and GCAL ensures consistent quality standards regardless of lifestyle demands. Same documentation validity as traditionally set stones.

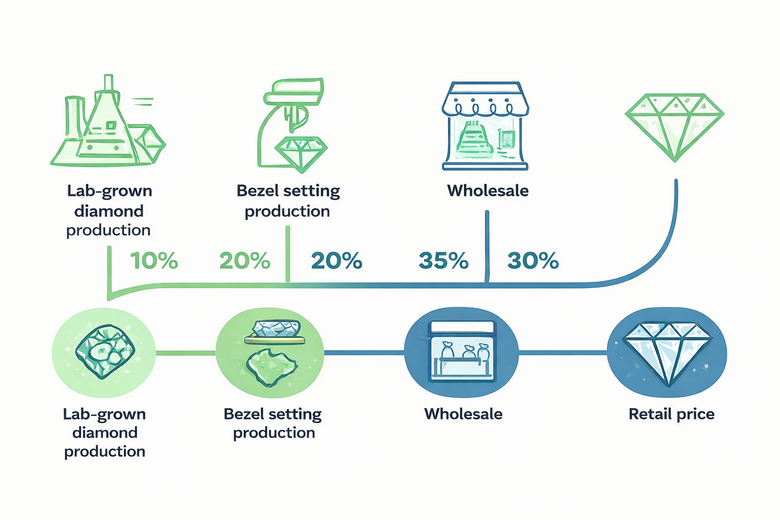

The Smart Money Movement: Ethical Luxury Without the Markup

Lab-grown diamond bezel rings offer superior cost-per-carat ratios with identical physical and optical properties. Direct manufacturer advantage eliminates multiple markup layers typical in traditional jewelry retail.

Here's the math: Traditional retail involves mining companies, rough dealers, cutting facilities, wholesalers, and retailers. Each adds markup. Final consumer prices can exceed production costs by 400-600%.

Transparent Pricing Structure Analysis

Direct manufacturer purchasing eliminates intermediary markups. This advantage becomes particularly significant for lab-grown diamonds where production costs are predictable and controllable.

Bezel setting production also favors direct relationships. The specialized metalworking and precise diamond measurement vary significantly among producers. Manufacturers specializing in bezel work achieve superior results through dedicated tooling and experienced craftspeople.

Long-term value considerations matter. Lab-grown diamonds maintain physical properties indefinitely. Well-crafted bezel settings protect and showcase stones throughout decades of wear. The durability advantage prevents chips and damage that significantly impact resale value.

Contemporary luxury consumers increasingly prioritize transparency, sustainability, and functional excellence over traditional rarity signaling.

2025's Biggest Wedding Trend Started with One Royal Ring

Meghan Markle's engagement ring catalyzed measurable shifts in wedding preferences. Royal influence demonstrates how celebrity choices rapidly influence consumers, particularly when aligning with broader cultural movements toward sustainability.

The minimalist sophistication trend extends beyond individual celebrity influence. It reflects fundamental changes in wedding planning approaches. Couples seek rings reflecting individual aesthetics, lifestyle requirements, and value systems rather than conforming to established conventions.

Social Media Influence on Design Preferences

Visual platforms favor jewelry designs that photograph well under various lighting conditions. Bezel settings offer photogenic advantages due to clean lines and reduced shadow complexity compared to prong settings.

The metal rim creates visual definition that translates effectively across camera systems and lighting environments. This contributes to social media momentum driving the trend forward.

Future projections look strong. Wedding industry forecasting suggests bezel popularity will continue expanding through 2025 and beyond. The convergence of practical lifestyle needs, aesthetic preferences, and ethical consumption patterns creates compound trend effects.

The lab-grown diamond component adds sustainability credentials resonating with environmentally conscious consumers. IGI, GIA, and GCAL certification standardization supports growing market confidence in these products.

The secure forever promise of bezel settings, combined with ethical luxury positioning of lab-grown diamonds, creates compelling value for couples beginning marriages with intentional choices reflecting personal style and social consciousness.

Why This Choice Reflects Modern Love

Bezel set lab-grown diamond wedding rings deliver unmatched durability, ethical transparency, and cost efficiency without compromising beauty. You get celebrity-inspired elegance, professional-grade security, and 60-80% savings. Perfect for active lifestyles, conscious values, and relationships built on substance over status.

Start Your Custom Design Journey Today

Labrilliante's direct manufacturer advantage eliminates markup layers while delivering IGI/GIA-certified lab diamonds in precision bezel settings. Book your consultation now to explore platinum, gold, and custom design options tailored to your lifestyle. Your modern love story deserves a ring engineered to last forever—protected, beautiful, and unapologetically smart.

Frequently Asked Questions

Bezel set lab-grown diamond rings typically cost $2,000-$8,000, while comparable mined diamond bezel rings range from $15,000-$50,000, representing 60-80% savings. The direct manufacturer purchasing model eliminates intermediary markups that can inflate traditional retail prices by 400-600%, making celebrity-inspired designs accessible at a fraction of the cost.

The low-profile design prevents snagging on medical gloves, equipment, and fabrics during daily activities, while the continuous metal rim eliminates prong loosening concerns from frequent handwashing and sanitization. This allows professionals to focus on their work without jewelry anxiety, as the bezel distributes pressure evenly and provides complete edge protection against impacts common in active environments.

Yes, bezels can make diamonds appear slightly smaller by covering precious millimeters of the stone's edges with metal, while prong settings create visual lift that maximizes perceived size. However, the 60-80% cost savings of lab-grown diamonds allows buyers to purchase larger carat weights that offset this size-minimizing effect, making it possible to achieve the desired visual impact while gaining superior security advantages.

Platinum bezels offer superior durability and maintain their appearance indefinitely without requiring additional treatments, while white gold bezels need periodic rhodium plating to stay bright over the years. When calculating 10-year ownership costs including maintenance, platinum often proves more cost-effective despite higher initial prices, making it ideal for couples prioritizing minimal long-term upkeep.

Full bezels provide maximum protection by enclosing the entire diamond perimeter, making them ideal for highly active professionals or those working with their hands frequently. Partial bezels protect vulnerable stone areas while maintaining better light exposure for enhanced brilliance, offering a middle ground for moderately active lifestyles. Flush settings position diamonds level with the metal surface for ultimate low-profile comfort, perfect for those who want absolute minimal interference in daily activities.

Bezel settings restrict light entry by covering pavilion edges, resulting in approximately 10-15% reduced light performance compared to prongs that expose 85-90% of the diamond surface. In practical terms, this difference is most noticeable in smaller stones under 0.75ct and in side-by-side comparisons, but for everyday wear, most people find the bezel's clean aesthetic and security benefits outweigh the slight sparkle reduction, especially when they can afford larger lab-grown stones.

Lab-grown diamonds in bezel settings receive identical certification from IGI, GIA, and GCAL laboratories, with the same documentation validity and grading standards applied to mined diamonds. CVD diamonds excel in bezel settings due to superior clarity grades and Type IIa purity, while HPHT diamonds offer excellent color consistency—both providing chemically identical carbon crystal structures with the same hardness and optical properties as natural diamonds formed over billions of years.

Schedule professional inspections every 6-12 months to check the bezel's structural integrity and ensure the metal rim maintains proper tension around the diamond, though bezel settings require less frequent maintenance than prong settings due to their superior stability. White gold bezels need rhodium replating every 1-2 years depending on wear, while platinum bezels can go several years between professional cleanings, making them particularly suitable for busy professionals who want minimal jewelry maintenance commitments.