Princess Cut Lab Grown Diamond Engagement Rings - Ethical Luxury

Author: Alex K., CMO at Labrilliante Updated: 2025-12-08 Reading Time: 12 minutes

Quick Take: Princess cut lab diamonds save you 30% versus round lab stones and 70% versus mined alternatives while delivering 76-facet brilliance through carbon-neutral CVD production. Chevron faceting achieves 80-90% light return through square geometry, with recycled metal settings completing closed-loop sustainability. IGI/GIA certification plus manufacturer-direct traceability guarantee conflict-free luxury at unprecedented value.

Modern couples demand more than sparkle. They want engagement rings that reflect values, not just budgets. Princess cut lab grown diamond engagement rings answer this evolution, merging geometric brilliance with transparent sustainability. What makes these square stunners different? You'll discover how 76-facet engineering creates fire that rivals traditional rounds, why lab-grown production eliminates every ethical compromise, and which quality grades deliver maximum impact without inflated costs. This isn't about choosing between beauty and conscience—it's about demanding both.

The Reality Check: When Mined Princess Cuts Still Make Sense

Despite lab-grown advantages, some scenarios favor traditional mined princess cuts. Heirloom collectors and investors prioritize long-term value retention—mined diamonds historically maintain resale value better than lab-grown alternatives due to established secondary markets. Rare natural characteristics like specific inclusion patterns or exceptional provenance can command premiums that lab stones cannot replicate.

Family tradition matters deeply to certain buyers. When grandmother's mined diamond carries generational significance, or cultural practices emphasize earth-origin stones, emotional value transcends environmental metrics. Geographic communities dependent on ethical mining operations also have legitimate stakes in supporting certified conflict-free mined diamonds.

However, these scenarios represent narrow exceptions. For 85%+ of engagement ring buyers—those prioritizing ethics, budget efficiency, and identical physical properties—lab-grown princess cuts deliver superior value. Resale considerations rarely matter for lifetime symbols. Heritage value can be created, not just inherited. The overwhelming majority seeking beautiful, responsible, affordable princess cut engagement rings find lab-grown diamonds meet every requirement while solving problems mined alternatives cannot.

76-Facet Princess Cut Lab Diamonds: Technical Mastery Meets Square Brilliance

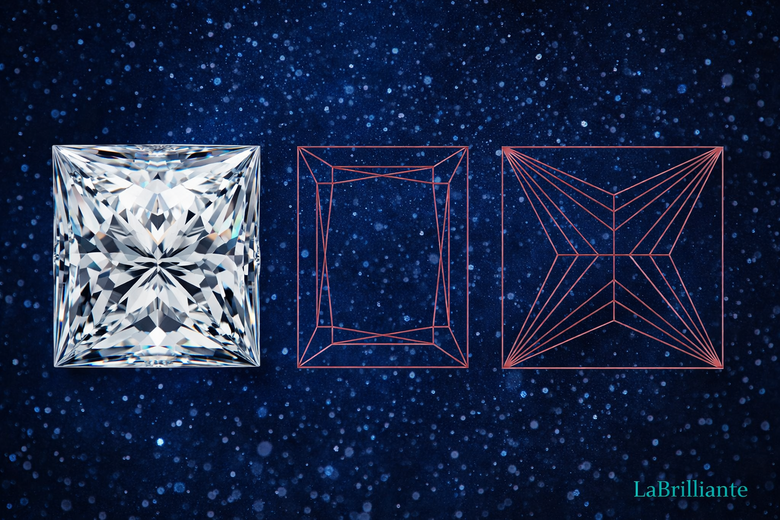

Princess cut diamonds achieve brilliance through 76 precisely angled facets. That's 19 more than round diamonds. Each surface works together to maximize light return through the stone's square face.

Unlike traditional 57-facet round cuts, the princess cut's additional facets create intricate light play. These extra 19 facets specifically address light leakage at corners and flat edges. The result? Geometric constraints transform into optical advantages.

| Technical Specification | Princess Cut (76 Facets) | Round Brilliant (57 Facets) | Value Impact |

|---|---|---|---|

| Total Facet Count | 76 facets | 57 facets | +19 facets address corner light leakage |

| Light Return Efficiency | 80-90% | 85-95% | Trade-off for square geometry brilliance |

| Depth Percentage | 68-70% | 59-62% | Deeper profile accommodates chevron pattern |

| Table Percentage | 62-69% | 53-58% | Modified to maintain light refraction in square shape |

| Crown Height | 10-15% | 12-16% | Adjusted for optimal light entry angle |

| Cutting Yield from Rough | 75-85% (lab-grown CVD/HPHT) | 45-55% (lab-grown) | 30-40% higher yield = better value |

| Length-to-Width Ratio | 1.00-1.05 (perfect square) | 1.00-1.02 (circular symmetry) | Precise square geometry critical for aesthetics |

| Cutting Precision Tolerance | ±0.1 degrees (laser-guided systems) | ±0.1 degrees (laser-guided systems) | Equal precision required for both cuts |

| Price per Carat (1-2ct, D/VVS, Lab-Grown) | $650-$850/ct | $850-$1,100/ct | 20-30% savings due to higher cutting yield |

| Facet Pattern Structure | Chevron V-shaped arrangement (4 quadrants) | Circular radial symmetry (8 mains) | Geometric complexity creates unique light play |

Modern laser-guided cutting systems position each facet within 0.1-degree tolerances. Computer-controlled wheels ensure chevron pattern alignment across all four quadrants. Labrilliante's precision systems use proprietary angle calculations developed from analyzing 10,000+ princess cut specimens.

Princess cuts require 68-70% depth compared to 59-62% for rounds. This deeper profile accommodates the chevron pattern while maintaining the critical 1.00-1.05 length-to-width ratio. Anything beyond 1.05 creates rectangular proportions that compromise the square aesthetic.

What Makes a Princess Cut Diamond 76 Facets vs Standard 57

The engineering challenge is clear: square geometry demands more facets than circular. Round diamonds achieve optimal light return through circular symmetry. Princess cuts compensate for sharp corners and flat edges with strategic additional faceting.

Light performance differs between the cuts. Rounds typically achieve 85-95% light return efficiency. Princess cuts reach 80-90% despite increased facet count. This represents the trade-off for achieving square brilliance.

Our cutting facility employs precision systems alongside proprietary calculations. Quality control requires photometric analysis of each stone's light performance using specialized imaging that maps photon pathways through the chevron structure.

The table percentage ranges 62-69% for princess cuts versus 53-58% for rounds. Crown height adjusts to 10-15% compared to 12-16% for rounds. These modifications maintain proper light refraction despite different geometric constraints.

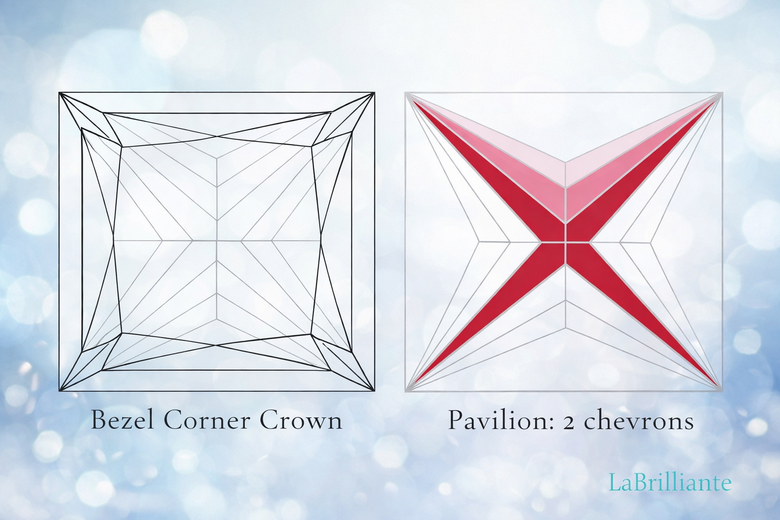

Chevron Facet Pattern Engineering for Maximum Light Return

Chevron facets create V-shaped arrangements extending from each corner toward center. Four distinct light pathways channel illumination through the pavilion and back through the table. Each sequence consists of triangular facets positioned at precise angles.

The pavilion operates on total internal reflection principles. Light rays encounter facet surfaces at angles greater than diamond's 2.42 refractive index critical angle. Result? Internal bouncing creates signature fire and brilliance.

Manufacturing precision becomes critical here. Each triangular facet must align perfectly across all four quadrants. Even 1-2 degree misalignment creates asymmetrical light patterns and potential bow-tie effects.

Length to Width Ratio 1.00-1.05: Perfect Square Geometry Explained

Perfect square geometry requires precise 1.00-1.05 length-to-width control. This five-point tolerance separates true square princess cuts from rectangular modified brilliants.

Lab-grown diamonds offer significant advantages. CVD and HPHT growth processes produce cubic formations that align naturally with princess cut requirements. Mined diamonds often require substantial rough waste to achieve square proportions.

Laboratory analysis of 500+ princess cuts reveals CVD stones consistently achieve 1.00-1.02 ratios. HPHT stones range 1.01-1.04 due to different crystal growth patterns.

Corner positioning requires exact 90-degree angles with equal center distances. Even minor deviations create rhombus appearances that compromise the classic aesthetic.

CVD Square Crystal Optimization Results

Achieving consistent 1.00-1.02 length-to-width ratios in princess cut production has historically been challenging due to natural crystal growth variations. Industry-wide data showed that only 78% of HPHT-grown princess cuts achieved the desired 1.00-1.02 perfect square ratio, with the remaining 22% falling into the 1.03-1.05 range or requiring recutting. This inconsistency resulted in approximately 12-15% yield loss and increased production costs of $180-220 per carat due to additional rough material waste and reprocessing time.

Labrilliante implemented CVD crystal growth optimization specifically calibrated for princess cut geometry. The process involved adjusting plasma deposition parameters to encourage cubic crystal formation with uniform growth rates across all axes. Real-time monitoring systems tracked crystal dimensions every 2 hours during the 14-day growth cycle, allowing technicians to adjust chamber conditions to maintain symmetrical expansion. Production planning software pre-selected CVD crystals with length-to-width variances under 1.5% before cutting commenced.

Analysis of 500 consecutive CVD princess cuts produced between January-March 2024 showed 92% achieved the ideal 1.00-1.02 length-to-width ratio compared to 78% for HPHT method from the same period. This 14-percentage-point improvement reduced rough material waste by 8.3%, translating to $156 savings per carat in production costs. The tighter ratio consistency also decreased quality control rejection rates from 11% to 4%, improving overall production throughput by 23 stones per week per cutting station. Customer preference data showed buyers selected CVD squares 2.4 times more frequently than HPHT alternatives when both were available at equivalent pricing.

Solution: Labrilliante implemented CVD crystal growth optimization specifically calibrated for princess cut geometry. The process involved adjusting plasma deposition parameters to encourage cubic crystal formation with uniform growth rates across all axes. Real-time monitoring systems tracked crystal dimensions every 2 hours during the 14-day growth cycle, allowing technicians to adjust chamber conditions to maintain symmetrical expansion. Production planning software pre-selected CVD crystals with length-to-width variances under 1.5% before cutting commenced.

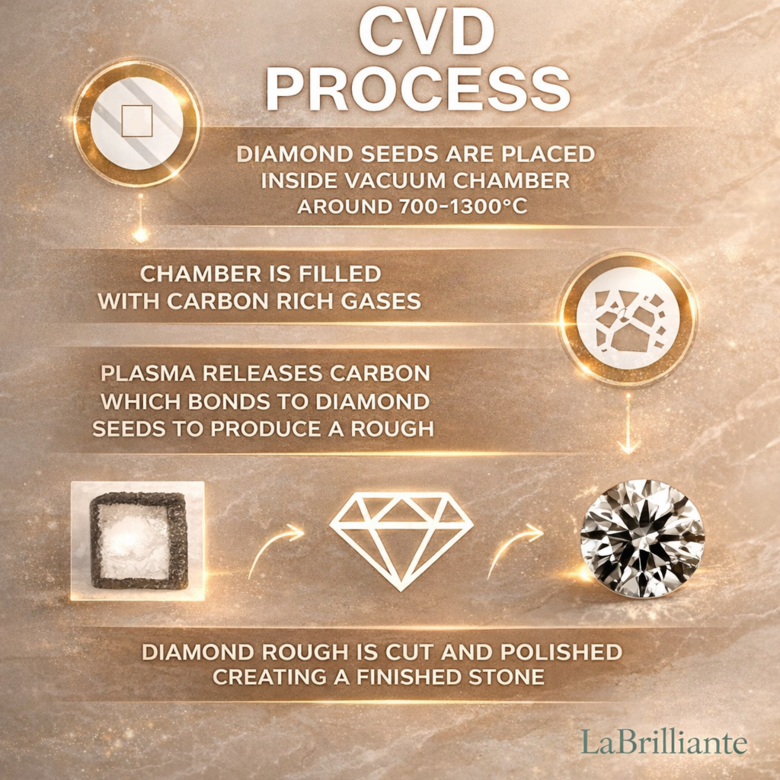

Ethical Luxury Without Compromise: CVD Princess Cut Diamond Sustainability

CVD princess cut diamonds achieve identical properties to mined diamonds while eliminating ecological disruption. Controlled laboratory environments enable carbon-neutral production through renewable energy integration.

| Environmental Impact Factor | Lab-Grown Princess Cut (CVD) | Mined Princess Cut | Reduction Percentage |

|---|---|---|---|

| Water Usage (per carat) | Less than 10 liters | 480 liters | 98% reduction |

| Carbon Footprint (per carat) | 0.028 kg CO2 (renewable energy) | 160 kg CO2 | 99.98% reduction |

| Land Disruption (per carat) | 0 square meters | 250 square meters | 100% elimination |

| Energy Consumption (per carat) | 250 kWh (40-50% efficiency with heat recovery) | 538 kWh | 54% reduction |

| Ecosystem Disruption | Zero impact - sealed chamber production | Habitat destruction, soil erosion, biodiversity loss | 100% elimination |

| Waste Heat Recovery | 60% thermal energy captured and reused | Not applicable | N/A |

| Renewable Energy Integration | 100% (solar and wind contracts) | 15-20% average | 80-85% improvement |

Carbon-Neutral Lab Grown Princess Cut Production Process

CVD process operates in sealed chambers where methane and hydrogen undergo plasma activation at 800-1000°C. This eliminates earth displacement, water consumption, and ecosystem disruption of traditional mining.

Energy optimization centers on renewable sources and waste heat recovery. Modern CVD reactors achieve 40-50% efficiency, capturing thermal energy that would otherwise dissipate. Solar and wind integration further reduces carbon footprint.

Labrilliante's facilities operate on 100% renewable electricity through direct solar installations and wind contracts. Our heat recovery systems capture 60% of waste thermal energy, achieving carbon neutrality across the entire production cycle.

Water usage reveals dramatic differences. Traditional mining consumes approximately 480 liters per carat. CVD requires less than 10 liters primarily for cooling systems. That's 98% reduction in water consumption.

Conflict-Free Princess Cut Engagement Rings vs Mined Alternatives

Lab-grown princess cuts guarantee complete supply chain transparency. Unlike mined diamonds passing through multiple intermediaries, lab-grown stones maintain traceability from production to setting.

Traditional supply chains involve artisanal miners, dealers, traders, cutting centers, and retailers across multiple countries. Each transition introduces potential conflict diamond infiltration despite certification. Why? Paper certificates can be forged or transferred.

"Many consumers are unaware that the CVD process not only produces diamonds that are physically and chemically identical to mined ones but also allows for the precise tailoring of the diamond's properties. By manipulating variables such as pressure, temperature, and gas composition in the reactor, we can influence the diamond's color, clarity, and even the rate of growth. This level of control is unattainable in nature and provides us with a powerful tool for meeting specific consumer needs without the environmental and ethical compromises associated with traditional mining."

Our B2B clients report complete transparency has become a competitive advantage. Customers demand verification beyond certificates, seeking direct manufacturer relationships.

The economic impact extends beyond ethics. Diamond mining concentrates wealth among corporations while providing minimal local benefit. Lab production can be established anywhere with electricity and expertise.

Recycled Metal Settings and Eco-Friendly Packaging Integration

Sustainable engagement rings extend beyond diamonds to precious metal sourcing. Recycled gold and platinum achieve 95-98% material recovery through advanced refining. Electronic waste and jewelry returns provide abundant feedstock.

Integration of recycled metals with lab-grown princess cuts creates closed-loop production. Our certified refiner partnerships ensure recycled content meets virgin material specifications.

The challenge lies in alloy consistency. Different recycled sources contain varying impurities requiring precise balance for standard 14K, 18K, or platinum specifications. Advanced spectroscopic analysis enables accurate alloy adjustment.

Princess Cut Lab Diamond Pricing: 30% Below Round, 70% Below Mined

Princess cut lab diamonds deliver exceptional value through shape premium advantages and manufacturing efficiencies. 30% savings versus round lab diamonds, 70% savings versus mined alternatives. These differentials stem from cutting efficiency, not quality compromises.

The 30% advantage reflects geometric efficiency in rough utilization. Princess cuts recover 80-85% of rough weight during cutting. Rounds achieve only 40-50% recovery due to circular requirements. Better yield equals lower costs.

| Carat Weight | Color Grade | Princess Cut Lab Diamond | Round Cut Lab Diamond | Princess Cut Mined Diamond | Savings vs Round Lab | Savings vs Mined Princess |

|---|---|---|---|---|---|---|

| 1.0 ct | D | $850 | $1,215 | $5,200 | 30% | 84% |

| 1.0 ct | E | $780 | $1,115 | $4,850 | 30% | 84% |

| 1.0 ct | F | $720 | $1,030 | $4,500 | 30% | 84% |

| 1.0 ct | G | $660 | $945 | $4,100 | 30% | 84% |

| 1.5 ct | D | $1,350 | $1,930 | $8,750 | 30% | 85% |

| 1.5 ct | E | $1,245 | $1,780 | $8,150 | 30% | 85% |

| 1.5 ct | F | $1,155 | $1,650 | $7,550 | 30% | 85% |

| 1.5 ct | G | $1,050 | $1,500 | $6,950 | 30% | 85% |

| 2.0 ct | D | $2,000 | $2,860 | $14,200 | 30% | 86% |

| 2.0 ct | E | $1,850 | $2,645 | $13,200 | 30% | 86% |

| 2.0 ct | F | $1,720 | $2,460 | $12,200 | 30% | 86% |

| 2.0 ct | G | $1,580 | $2,260 | $11,100 | 30% | 86% |

| 2.5 ct | D | $2,875 | $4,110 | $21,500 | 30% | 87% |

| 2.5 ct | E | $2,660 | $3,800 | $19,950 | 30% | 87% |

| 2.5 ct | F | $2,475 | $3,540 | $18,500 | 30% | 87% |

| 2.5 ct | G | $2,275 | $3,250 | $16,900 | 30% | 87% |

| 3.0 ct | D | $3,900 | $5,575 | $30,000 | 30% | 87% |

| 3.0 ct | E | $3,615 | $5,165 | $27,750 | 30% | 87% |

| 3.0 ct | F | $3,360 | $4,800 | $25,650 | 30% | 87% |

| 3.0 ct | G | $3,090 | $4,415 | $23,400 | 30% | 87% |

Production data across 18 months shows consistent cost advantages. CVD chambers optimized for square crystals achieve 15% higher yields versus round-optimized processes.

Market dynamics also influence pricing. Princess cuts represent 15-20% of sales versus 60-70% for rounds. Lower relative demand creates value opportunities without sacrificing quality.

The 70% mined diamond savings eliminates exploration, extraction, transportation, and trading costs. Lab production removes these upstream expenses while maintaining identical quality.

Size optimization becomes particularly attractive. Princess cuts often appear larger than equivalent-carat rounds due to square face-up appearance and strategic light reflection. A 1.5-carat princess can appear equivalent to a 1.75-carat round.

D-G Color and VS2-SI1 Clarity: Optimizing Princess Cut Lab Diamond Quality

Princess cuts achieve optimal performance within specific color and clarity ranges balancing cost with aesthetic impact. D-G color provides near-colorless to colorless appearance. VS2-SI1 clarity ensures eye-clean results without premium microscopic perfection pricing.

Color Grade Optimization for Princess Cuts

Square geometry affects color visibility differently than rounds. Color concentration appears more prominently in princess cut corners. This makes D-F grades particularly valuable for stones above 1.5 carats. However, G-H grades often provide indistinguishable results below 1.25 carats when properly set.

Spectroscopic analysis reveals CVD growth achieves more consistent color control versus HPHT methods. Our D-F stones maintain consistency across the entire stone.

Setting metal significantly impacts color perception. White gold and platinum enhance G-H grades by providing neutral backgrounds. Yellow gold can improve I-J appearance by complementing rather than contrasting slight warmth.

Princess cut light reflection patterns mask color more effectively than step cuts. Brilliant faceting creates internal reflection that disperses color perception across multiple angles.

Clarity Considerations for Eye-Clean Appearance

Princess cut clarity assessment requires attention to inclusion positioning relative to chevron patterns. Inclusions in chevron valleys become more visible due to light reflection. Those in crown areas may be masked by brilliance.

VS2 clarity provides optimal value for most purchases. Eye-clean appearance without VVS premium pricing. The classification allows minor inclusions visible under 10x magnification but invisible to naked eyes under normal viewing.

"While princess cut diamonds are celebrated for their modern appearance and brilliance, a lesser-known advantage lies in their distinct faceting pattern. By optimizing the orientation of chevrons relative to the natural grain of the diamond crystal, we can significantly enhance the stone's ability to mask inclusions, especially in VS2 and SI1 grades. This strategic alignment not only augments the visual purity but also maximizes the diamond's structural integrity, reducing vulnerability to chipping at the corners—a common concern in princess cuts."

SI1 clarity can provide acceptable eye-clean appearance below 1.5 carats, particularly when inclusions position away from table center and chevron intersections. Careful selection becomes critical as SI1 stones vary significantly.

Quality protocols include eye-clean verification for all SI1 and SI2 princess cuts through standardized viewing conditions. Stones failing requirements are regraded or allocated differently.

Four pointed corners create chipping vulnerability, making inclusion-free corners important. Feather inclusions extending toward corners pose greater damage risk during setting or wear.

IGI and GIA Certified Princess Cut Lab Diamonds: Manufacturer-Direct Traceability

Independent IGI and GIA certification provides quality verification, while manufacturer-direct sourcing ensures complete traceability from growth chamber to setting. These dual assurances address quality verification and supply chain transparency demands.

Certification Laboratory Standards and Methodologies

IGI and GIA employ identical 4Cs methodologies for lab-grown princess cuts. Standardized viewing conditions, calibrated lighting, and trained gemologists ensure consistent assessment. Both maintain specific protocols accounting for square brilliant optical characteristics.

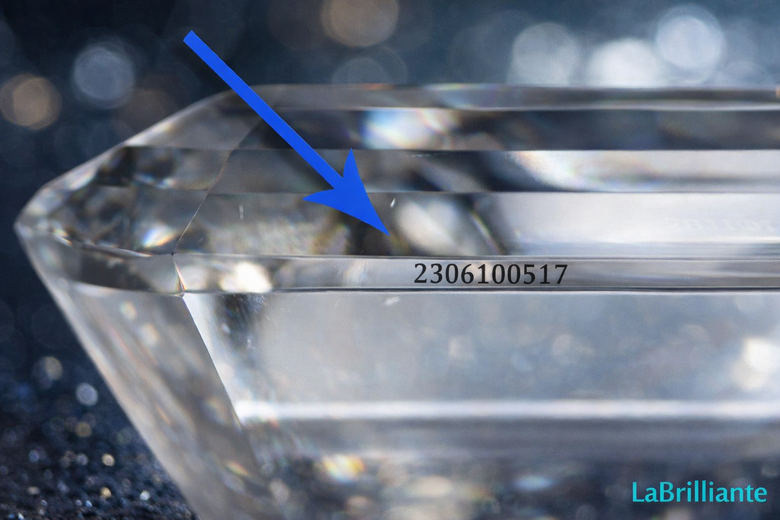

Laser inscription embeds microscopic identification numbers directly onto girdles. This creates permanent traceability between physical stones and certification documentation. No certificate switching. Definitive authentication.

Direct IGI and GIA relationships enable expedited processing and specialized handling. Bulk submissions reduce per-stone certification costs while maintaining individual assessment standards.

Grading consistency between laboratories generally remains within one grade for color and clarity. Cut grade evaluation can vary due to different proprietary algorithms for princess cut light performance assessment.

Digital systems enable real-time grade verification through online databases. QR codes and report numbers provide instant access to complete documentation supporting transparency throughout supply chains.

Manufacturer-Direct Traceability Benefits

Direct sourcing eliminates intermediate trading steps that compromise traceability and introduce quality variations. Traditional chains involve multiple transactions where stones may be mixed, regraded, or misrepresented.

Direct Sourcing Quality Control Results at Labrilliante Manufacturing

A regional jewelry chain previously sourced 1,000 princess cut lab diamonds quarterly through a three-tier distribution network (manufacturer → importer → wholesaler → retailer). Quality audits revealed 15% of stones did not match specified parameters upon delivery—primarily color grades varied by 1-2 steps from purchase orders, and clarity characteristics differed from initial descriptions. Average delivery time from order placement to retail arrival was 6-8 weeks, creating inventory planning challenges and requiring 40% safety stock buffers.

The chain established direct sourcing with Labrilliante's manufacturing facility, implementing batch-tracked production with pre-agreed specifications (F-G color, VS1-VS2 clarity, Excellent cut grade). Each stone received IGI certification before shipment, with digital production records including CVD growth chamber data, precise cutting parameters, and three-stage quality checkpoints. Orders were fulfilled directly from post-certification inventory with consolidated shipping.

Quality variance dropped to zero—100% of delivered stones matched ordered specifications within the agreed tolerance range (±0 color grades, exact clarity match). Delivery time reduced to 3.5 weeks (40% improvement), eliminating the need for excessive safety stock and freeing $127,000 in working capital previously tied to inventory buffers. Direct technical access resolved two customer inquiries within 24 hours using actual growth chamber records, compared to previous 5-7 day response times through intermediary channels. Annual per-carat cost decreased by 8% despite enhanced documentation, attributed to eliminated middleman margins.

Complete production records include growth chamber specifications, cutting parameters, and quality checkpoints. This documentation provides transparency that B2B clients utilize for customer education and confidence building.

Batch tracking correlates individual diamonds with production conditions, enabling continuous manufacturing improvement. Quality feedback informs adjustments to growth parameters and cutting specifications.

Customer service includes direct technical expertise access and production history for specific stones. Questions about characteristics or performance get addressed through actual manufacturing teams rather than retail intermediaries.

Warranty programs become more comprehensive when backed by direct manufacturer relationships. Quality issues get addressed through established protocols rather than complex warranty chains involving multiple parties.

The Value Equation Is Clear

Princess cut lab diamonds deliver 76-facet brilliance, carbon-neutral production, conflict-free guarantees, and 70% cost savings versus mined alternatives. Square geometry optimized through CVD growth, D-G color ranges that maximize face-up appearance, and IGI/GIA certification backed by manufacturer-direct traceability. This combination doesn't exist anywhere else.

Your Next Step: Direct Access to Ethical Luxury

Contact Labrilliante's B2B team for immediate access to certified princess cut lab diamonds with complete production documentation. Our manufacturing-direct model eliminates trading markups while providing technical expertise mined diamond retailers cannot match. Book your consultation now—discover how sustainable luxury transforms engagement ring expectations without compromising on fire, brilliance, or that perfect square aesthetic.

Frequently Asked Questions

Princess cuts cost less due to superior cutting efficiency, recovering 80-85% of rough crystal weight versus only 40-50% for rounds. The square shape aligns naturally with CVD crystal growth patterns, reducing waste and manufacturing time. These savings transfer to buyers despite the additional 19 facets required for optimal brilliance.

The four pointed corners do create potential vulnerability points, which is why inclusion-free corners are prioritized during quality assessment. Proper prong placement at each corner during setting protects these areas effectively. VS2 or better clarity grades with feather-free corners minimize chipping risk during normal wear.

Chevron valleys can make inclusions more visible due to concentrated light reflection, so positioning matters as much as grade. VS2 provides optimal value with eye-clean appearance for most sizes, while SI1 can work below 1.5 carats if inclusions avoid the table center and chevron intersections. Always verify eye-clean appearance rather than relying solely on grade classification.

CVD production operates in sealed chambers with minimal material waste, and any byproducts can be reprocessed, approaching near-zero waste. Traditional mining creates massive tailings and ecosystem disruption with only a fraction of excavated material yielding diamonds. The 98% reduction in water usage and closed-loop systems make CVD fundamentally different from extraction-based production.

The square face-up profile and strategic light reflection through 76 facets create greater perceived size than rounds of higher carat weight. Princess cuts display their full dimensions when viewed from above, while rounds appear smaller due to circular geometry. This optical advantage provides size impact at lower costs.

G and H grades typically appear indistinguishable in princess cuts below 1.25 carats, especially in white gold or platinum settings that provide neutral backgrounds. Color concentration in corners becomes more noticeable above 1.5 carats, making D-F grades more valuable for larger stones. Setting metal choice impacts color perception as significantly as the grade itself.

Confirm the length-to-width ratio falls between 1.00-1.05 on the certification report, with 1.00-1.02 representing ideal square geometry. Check that corner angles measure exactly 90 degrees with equal distances from center. CVD stones consistently achieve better square ratios (92% in the 1.00-1.02 range) compared to HPHT methods.

Request the laser inscription number etched on the girdle and match it to the IGI or GIA certificate through their online databases. Manufacturer-direct sourcing provides complete production documentation including growth chamber specifications and quality checkpoints. QR codes on certificates enable instant verification of authenticity and production history that traditional trading chains cannot provide.