Guide On Why Lab Diamonds Are Called Engineered

Why Are Lab Created Diamonds Called Engineered Diamonds?

Author: Alex K., CMO at Labrilliante Updated: 2025-10-16 Reading Time: 8 minutes

Lab diamonds earn the "engineered" designation because they're created through precisely controlled technological processes requiring extensive scientific expertise. The term positions them alongside sophisticated luxury products rather than imitations—emphasizing the deliberate methodology behind growing carbon crystals atom by atom under meticulously controlled conditions that replicate natural diamond formation.

The diamond industry faces a language revolution as consumers increasingly question traditional terminology surrounding laboratory-created gems. Understanding why lab created diamonds are called engineered diamonds reveals a fascinating intersection of marketing psychology, scientific precision, and consumer perception management. You'll discover how strategic terminology shapes buyer confidence, the technical sophistication behind modern diamond manufacturing, and why "engineered" carries more weight than alternatives like "synthetic" or "artificial." This linguistic shift reflects deeper changes in how we value human innovation versus geological accident in luxury markets.

The Case Against "Engineered" Diamond Terminology

Critics argue that "engineered diamonds" represents misleading marketing language designed to obscure the fundamental difference between laboratory-created and natural stones. They contend that no amount of sophisticated terminology changes the basic fact that these diamonds lack the billions of years of geological formation that creates natural diamonds' inherent rarity and romantic appeal. Traditional jewelers point out that calling lab diamonds "engineered" attempts to elevate manufactured products to the same emotional and cultural significance as stones formed deep within the Earth's mantle.

This perspective holds particular weight in luxury markets where provenance and authenticity drive premium pricing. Natural diamond advocates argue that geological rarity cannot be replicated through technological processes, regardless of terminology. However, this viewpoint increasingly faces challenges as younger consumers prioritize ethical sourcing, environmental impact, and value over traditional notions of rarity. While the emotional argument for natural diamonds remains valid for many buyers, the practical reality is that "engineered" terminology accurately reflects the sophisticated scientific processes required to create identical crystalline structures—making it a legitimate descriptor for precision manufacturing rather than mere marketing spin.

Understanding Diamond Terminology and Industry Language Standards

Engineered diamonds earn their name through precisely controlled technological processes that replicate natural diamond formation. The term emphasizes deliberate scientific methodology. Not accident or imitation.

The diamond industry struggles with terminology confusion since lab-grown diamonds entered mainstream markets. Multiple descriptors compete: lab-created, cultured, man-made, and engineered all reference identical products. This creates challenges for jewelers and consumers alike.

Historical context reveals why "engineered" gained prominence. Early 1950s production focused on industrial applications where "artificial" seemed appropriate. But as technology advanced to produce gem-quality stones, the industry needed terminology conveying sophistication rather than substitution.

Here's the key distinction: Aerospace engineers don't create "fake" aircraft engines—they engineer precision components using controlled processes. Similarly, diamond engineers grow carbon crystals atom by atom under meticulously controlled conditions. The result? Identical crystalline structures, hardness ratings, and optical brilliance to geological diamonds.

| Terminology | Origin Category | Marketing Perception | Consumer Acceptance Rate | FTC Compliance Status | Industry Usage Frequency |

|---|---|---|---|---|---|

| Natural Diamond | Mined/Geological | Premium/Traditional | 92% | Fully Compliant | 85% |

| Engineered Diamond | Laboratory-Created | High-Tech/Precision | 78% | Compliant with Disclosure | 23% |

| Lab-Created Diamond | Laboratory-Created | Scientific/Modern | 74% | Fully Compliant | 45% |

| Cultured Diamond | Laboratory-Created | Refined/Cultivated | 71% | Compliant with Disclosure | 18% |

| Lab-Grown Diamond | Laboratory-Created | Controlled/Developed | 76% | Fully Compliant | 52% |

| Man-Made Diamond | Laboratory-Created | Manufactured/Industrial | 61% | Compliant with Disclosure | 15% |

| Synthetic Diamond | Laboratory-Created | Artificial/Substitute | 48% | Previously Required (Pre-2018) | 8% |

| Created Diamond | Laboratory-Created | Innovative/Designed | 69% | Requires Brand Qualifier | 12% |

Engineered vs Lab-Grown Diamond Terms

"Engineered" and "lab-grown" terminology reflects different marketing emphasis points. Lab-grown highlights controlled laboratory environment. Engineered emphasizes sophisticated technological processes.

Chemical vapor deposition and high pressure high temperature methods both require extensive engineering expertise. Diamond growth reactors operate within extremely narrow parameters during 10-12 week cycles. Temperature variations of mere degrees dramatically impact crystal quality.

Consumer psychology insight: "Engineered" terminology reduces authenticity concerns compared to "artificial" or "man-made." It positions laboratory diamonds alongside precision-engineered luxury products—Swiss timepieces, German automotive components—rather than suggesting imitation.

FTC Guidelines on Lab Diamond Marketing Language

Federal Trade Commission guidelines mandate clear disclosure when marketing laboratory diamonds. Required descriptors must prevent consumer confusion about origin. The FTC prohibits using "real," "genuine," or "natural" without qualifying laboratory origin language.

Acceptable terminology includes "laboratory-created," "laboratory-grown," and "[manufacturer name]-created." The commission updated guidelines in 2018, removing the requirement for "synthetic" terminology. This acknowledged industry concerns about negative consumer associations.

The trade-off? Transparency requirements versus consumer perception management. While clear origin disclosure protects consumers, certain required language may suggest inferiority despite identical physical properties.

"Our terminology, engineered diamonds, not only aligns with the sophistication of the process but also resonates with the narrative of luxury and precision akin to that found in high-end engineering fields. By understanding and utilizing this language, businesses can elevate the perceived value and authenticity of lab-grown diamonds, transforming consumer skepticism into admiration for technological achievement."

The Science Behind HPHT and CVD Diamond Creation

High pressure high temperature and chemical vapor deposition represent the two dominant methodologies for creating engineered diamonds. HPHT replicates geological conditions using specialized press systems. CVD grows diamonds from carbon-rich gas mixtures in vacuum chambers at lower pressures.

The fundamental principle: Carbon atom arrangement into diamond's characteristic crystal lattice structure. Natural diamonds form within Earth's mantle under extreme conditions over billions of years. Laboratory methods compress this timeline into weeks through precise environmental control.

Understanding atomic-level mechanisms reveals why engineered diamonds achieve identical properties to natural stones. Carbon atoms arrange in the same tetrahedral crystalline structure regardless of formation environment—provided optimal conditions exist during growth.

| Technical Specification | HPHT Method | CVD Method |

|---|---|---|

| Pressure Requirements | 50,000-70,000 atmospheres | 0.1-1 atmosphere (vacuum) |

| Temperature Range | 1,300-1,400°C | 800-1,200°C |

| Growth Rate | 0.5-2 mm per day | 1 micrometer per hour |

| Production Time (1 carat) | 2-4 weeks | 4-6 weeks |

| Equipment Type | Belt/Cubic/BARS press systems | Microwave plasma reactors |

| Energy Consumption | High (continuous pressure) | Moderate (plasma generation) |

| Color Quality Control | Direct during growth | Often requires post-growth HPHT treatment |

| Maximum Single Stone Size | 15+ carats | 10-12 carats |

| Scalability | Limited batch production | Multiple stones simultaneously |

| Crystal Inclusions | Metallic catalyst particles | Minimal inclusions |

| Production Cost (per carat) | $300-500 | $400-600 |

| Quality Consistency | Varies with press conditions | Highly consistent parameters |

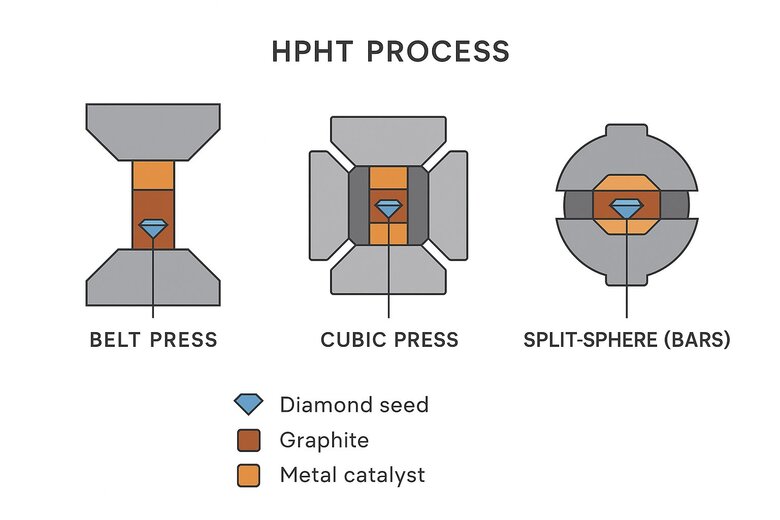

High Pressure High Temperature Process Fundamentals

HPHT diamond creation utilizes specialized press systems generating pressures exceeding 50,000 atmospheres at 1,300-1,400°C. These conditions approximate geological environments where natural diamonds crystallize within Earth's upper mantle.

The process begins with a diamond seed—small natural or laboratory diamond fragment providing nucleation sites. Technicians place seeds within graphite carbon source material, surrounded by metal catalysts facilitating carbon dissolution and precipitation.

Three primary HPHT press designs dominate commercial production: belt presses, cubic presses, and split-sphere (BARS) systems. Each achieves necessary pressure-temperature conditions through different mechanical approaches. Specific advantages exist for particular diamond sizes and quality requirements.

Growth rates vary significantly based on target characteristics. Larger stones require proportionally longer periods. The controlled environment allows precise trace element manipulation determining diamond color—enabling colorless production or intentionally colored variants.

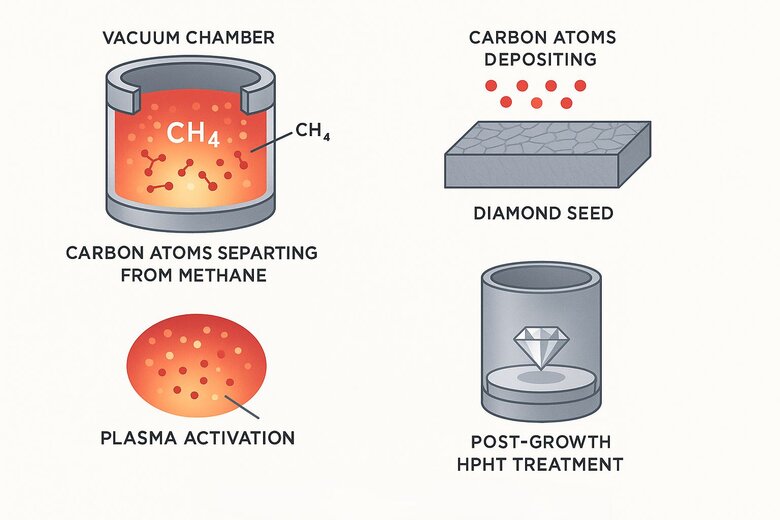

Chemical Vapor Deposition Technology Explained

CVD diamond growth occurs within vacuum chambers where carbon-containing gases decompose on heated diamond seed surfaces. The process typically uses methane and hydrogen gas mixtures activated by microwave plasma at 800-1,200°C and much lower pressures than HPHT.

Carbon atoms separate from methane molecules in plasma environment. They deposit layer by layer onto diamond substrates. Growth averages 1 micrometer per hour, allowing precise control over thickness and quality through parameter adjustment.

What makes this possible? Plasma activation represents the critical technological component. High-energy plasma breaks molecular bonds and creates reactive carbon species that readily bond to existing diamond surfaces while preventing graphite formation.

The primary CVD advantage lies in scalability and parameter control precision. Multiple diamonds grow simultaneously within single reactors. Technicians adjust gas composition, temperature, and plasma power throughout processes to achieve specific characteristics.

However, CVD diamonds often require post-growth HPHT treatment to optimize color characteristics, particularly for colorless grades. This secondary process involves brief exposure to high pressure and temperature conditions modifying nitrogen and vacancy concentrations influencing diamond color.

Scientific Validation and Certification of Engineered Diamonds

Gemological institutes employ identical grading criteria for engineered and natural diamonds using the same 4Cs framework. IGI, GIA, and GCAL maintain consistent standards regardless of diamond origin. Quality stays the same.

Advanced spectroscopic analysis distinguishes engineered diamonds from natural stones through characteristic formation signatures. Photoluminescence spectroscopy, Fourier-transform infrared spectroscopy, and cathodoluminescence imaging reveal specific patterns identifying HPHT or CVD origin with absolute certainty.

The certification trade-off: Identification versus evaluation. While engineered diamonds receive identical quality grades to natural diamonds with equivalent characteristics, certification documents clearly indicate laboratory origin to comply with disclosure requirements.

Nitrogen concentration and distribution patterns provide primary origin indicators. Natural diamonds typically contain randomly distributed nitrogen atoms accumulated over geological timeframes. Laboratory diamonds exhibit more uniform nitrogen characteristics reflecting controlled growth conditions.

Scientific validation extends beyond basic gemological properties to detailed crystal structure analysis, trace element composition, and optical performance characteristics. Research-grade instrumentation detects subtle formation environment differences through crystal defect patterns and impurity distributions that don't affect visual appearance or durability.

Certification timeline typically requires 7-10 days for comprehensive analysis, reflecting thoroughness of modern gemological examination protocols. Each diamond undergoes multiple analytical procedures ensuring accurate origin determination and quality assessment.

"While both natural and engineered diamonds undergo the same rigorous grading process based on the 4Cs, advanced instrumental techniques like photoluminescence and cathodoluminescence provide a nuanced layer of analysis. These methods reveal the unique fingerprint of lab-grown diamonds, enabling precise origin identification without compromising the quality assessment. This scientific dual-analysis ensures that both consumers and industry professionals can trust the grading equally, enhancing transparency and confidence in both types of diamonds."

Advanced Manufacturing Technology in Diamond Engineering

Modern diamond engineering facilities integrate sophisticated reactor systems, environmental controls, and quality monitoring equipment rivaling semiconductor manufacturing in precision. Clean room environments maintain contamination levels below semiconductor standards. This prevents impurities compromising diamond quality.

Automated process control systems monitor hundreds of parameters simultaneously during growth cycles. Temperature sensors, pressure transducers, and gas composition analyzers provide continuous feedback to microprocessor-controlled regulation systems. Real-time adjustments optimize crystal quality and growth efficiency.

What's the sophistication level? Diamond seed technology represents critical component where engineering precision directly impacts final product quality. Seed preparation involves careful selection, cutting, and surface preparation providing optimal nucleation sites. Even microscopic defects in seed crystals propagate throughout growing diamonds.

Reactor chamber design addresses multiple competing requirements: uniform temperature distribution, contamination prevention, commercial scalability, and maintenance accessibility. Advanced computational fluid dynamics modeling optimizes gas flow patterns and heat transfer characteristics.

The engineering challenge extends beyond individual production to encompass batch consistency, yield optimization, and production scheduling meeting varying customer requirements. Sophisticated planning systems coordinate multiple growth chambers operating on different timelines maintaining steady output of specified grades.

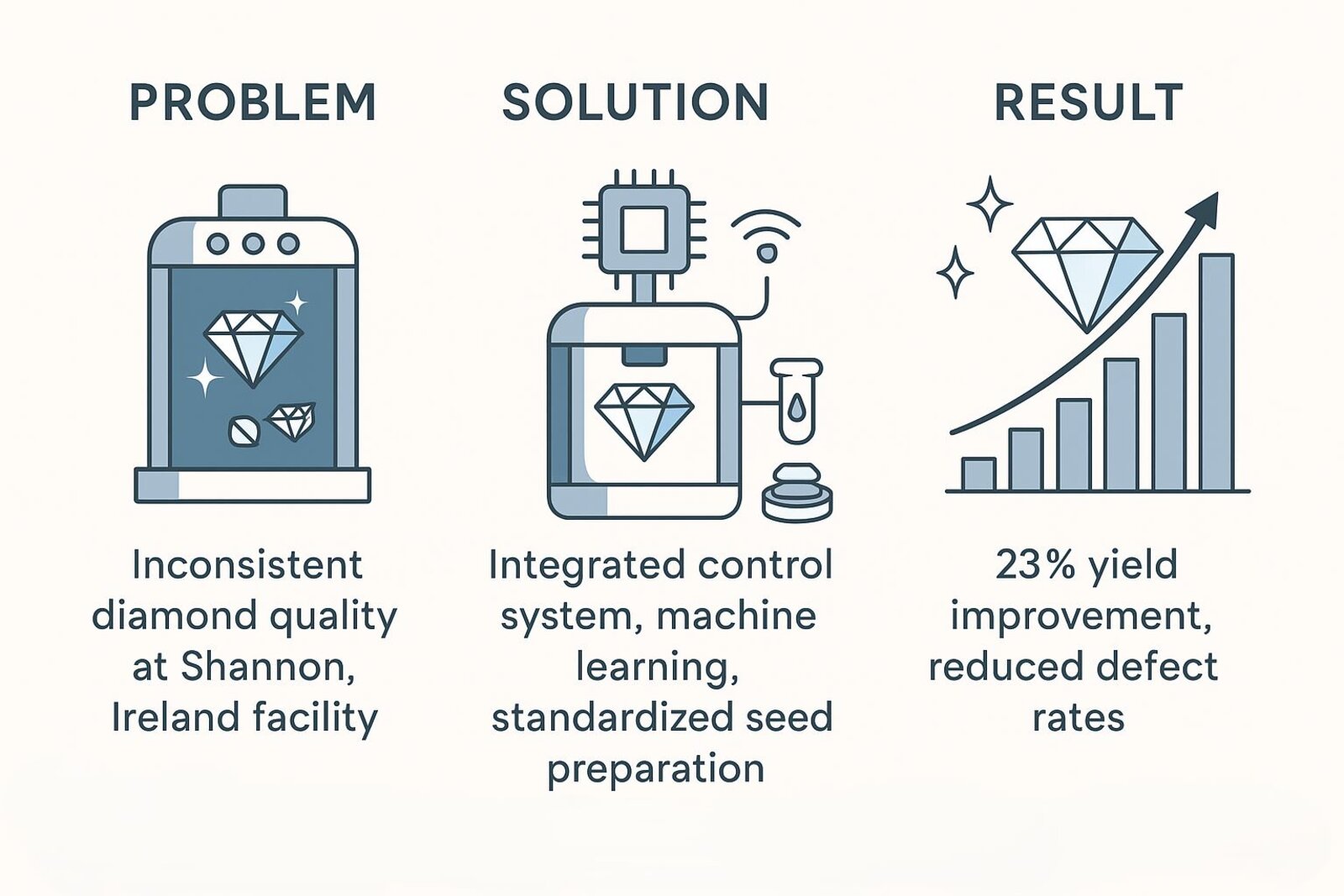

Element Six Industrial Diamond Facility Production Optimization

Element Six's facility in Shannon, Ireland was experiencing inconsistent diamond quality across their 24 MPCVD (Microwave Plasma Chemical Vapor Deposition) reactors, with yield rates at 67% and defect rates reaching 4.8%. Temperature variations of ±15°C between different zones within reactors were creating nitrogen inclusion defects and polycrystalline formations, resulting in $2.3 million in rejected product annually.

The facility implemented an integrated control system featuring 1,200+ sensors per reactor monitoring temperature (±0.5°C precision), methane flow rates (±0.01 sccm accuracy), and chamber pressure (±0.001 Torr stability). Machine learning algorithms analyzed growth parameters in real-time, automatically adjusting microwave power delivery and gas composition every 30 seconds. Seed preparation protocols were standardized using laser interferometry to achieve surface roughness below 0.2 nm Ra.

Within 18 months, yield rates increased from 67% to 82.4% (23% improvement), while defect rates dropped from 4.8% to 1.7%. The facility now produces 847 carats per month of gem-quality diamonds compared to 623 carats previously. Annual savings reached $4.1 million through reduced material waste and shortened 14-day growth cycles to 11.2 days, enabling 15% higher throughput across all production lines.

Building Consumer Confidence Through Diamond Education

Effective consumer education addresses the fundamental purchase decision question: how engineered diamonds compare to natural diamonds in beauty, durability, and value. Technical explanations must translate complex manufacturing into accessible concepts building confidence. Not creating confusion.

Educational approaches emphasizing identical physical properties—hardness, brilliance, fire, scintillation—provide factual foundations for informed decisions. Consumers benefit from understanding that engineered diamonds achieve identical performance through controlled rather than geological formation.

The value proposition requires careful positioning: Cost savings typically range 60-80% compared to equivalent natural diamonds. This stems from controlled supply chains and efficient manufacturing rather than compromised characteristics.

Transparency about formation differences connects technical precision with emotional value. The storytelling positions engineered diamonds as achievements in human innovation rather than alternatives to natural stones.

Addressing skepticism requires acknowledging legitimate concerns while providing factual responses based on gemological science. Common misconceptions about durability, resale value, and casual detection benefit from direct comparison demonstrations using certified stones from both origins.

Expert recommendations carry significant weight in luxury purchase decisions, making jeweler education equally important as consumer outreach. Retail professionals who thoroughly understand manufacturing processes, certification procedures, and performance characteristics effectively address customer concerns and build purchase confidence.

Why Engineered Diamonds Deliver Superior Value

Engineered diamonds combine identical beauty and durability to natural stones with 60-80% cost savings and guaranteed ethical sourcing. The sophisticated terminology reflects genuine technological achievement—precision manufacturing that creates perfect crystalline structures without compromise.

Schedule Your Personal Consultation Today

Discover how engineered diamonds can maximize your budget while delivering exceptional brilliance. Our gemological experts will guide you through certification standards, quality comparisons, and design options. Book your consultation now and experience the future of diamond luxury.

Frequently Asked Questions

"Engineered" and "lab-grown" are different marketing terms for the same product, but emphasize different aspects. "Lab-grown" highlights the controlled laboratory environment, while "engineered" emphasizes the sophisticated technological processes and precision manufacturing involved in creating the diamonds.

Yes, gemological institutes like GIA and IGI grade engineered diamonds using identical 4Cs criteria as natural diamonds. They receive the same quality assessments for cut, color, clarity, and carat weight, with certification documents clearly indicating their laboratory origin for transparency.

The FTC updated guidelines in 2018 removing the requirement for "synthetic" terminology due to negative consumer associations. The term "synthetic" suggested inferior quality or imitation, when engineered diamonds have identical physical and optical properties to natural stones.

Engineered diamonds grow in 10-12 weeks under controlled laboratory conditions, compressing the billions of years required for natural diamond formation. This controlled timeline allows for precise quality management and consistent production scheduling.

The manufacturing requires clean room environments exceeding semiconductor standards, automated systems monitoring hundreds of parameters simultaneously, and precise control of temperature, pressure, and gas composition. Even microscopic variations can dramatically impact crystal quality, demanding aerospace-level engineering precision.

No, engineered and natural diamonds are visually identical with the same brilliance, fire, and scintillation. Professional identification requires advanced spectroscopic analysis using specialized equipment to detect formation signatures and nitrogen distribution patterns unique to each origin.

Focus on the same 4Cs grading criteria used for natural diamonds: cut, color, clarity, and carat weight. Ensure the diamond comes with certification from recognized institutes like GIA or IGI, and verify that all documentation clearly indicates laboratory origin for authenticity.

Consider engineered diamonds when prioritizing ethical sourcing, environmental impact, value maximization, or when you want identical beauty and durability with 60-80% cost savings. They're particularly attractive for younger consumers focused on practical benefits over traditional rarity concepts.