Why Lab Diamonds Are Called Eco Friendly

Why Lab Created Diamonds Are Called Eco Friendly Diamonds

Author: Alex K., CMO at Labrilliante Updated: 2025-10-16 Reading Time: 8 minutes

Lab created diamonds eliminate 99% of environmental impact through zero mining disruption, operating in 500 square meter facilities versus kilometer-wide craters. CVD and HPHT technologies consume 86% less water per carat while enabling solar-powered production. Independent certification bodies verify these sustainability claims through standardized environmental audits.

Modern luxury consumers face an unprecedented dilemma: choosing between traditional symbols of love and environmental responsibility. The jewelry industry's transformation reflects broader cultural shifts toward sustainable consumption without compromising quality or meaning. Understanding why lab created diamonds earn their eco-friendly reputation reveals how technology revolutionizes centuries-old practices. This analysis examines verified environmental data, production methods, and certification standards that distinguish laboratory diamonds from their mined counterparts.

The Energy Intensity Challenge: When Lab Production Isn't Always Greener

Lab diamond critics point to significant energy consumption during CVD and HPHT production processes. Creating diamonds at 2000°C requires substantial electricity, and facilities drawing power from coal-heavy electrical grids can generate higher carbon emissions per carat than some efficient mining operations. Countries with renewable energy penetration below 30% may see lab diamonds producing 40-60% more emissions than advertised.

This argument holds merit in regions dependent on fossil fuel electricity generation, particularly during peak production periods when renewable sources provide insufficient baseload power. However, the fundamental difference lies in scalability and location flexibility. Lab facilities can relocate to renewable-rich regions or invest in dedicated solar installations, while mining operations remain geographically constrained to deposit locations regardless of local energy infrastructure.

The energy criticism becomes less relevant as global renewable adoption accelerates and production facilities increasingly integrate dedicated clean energy systems. Unlike mining's permanent geographic limitations, lab production's mobility enables continuous optimization toward genuine carbon neutrality.

The Environmental Impact Reality: Earth Excavation and Ecosystem Destruction

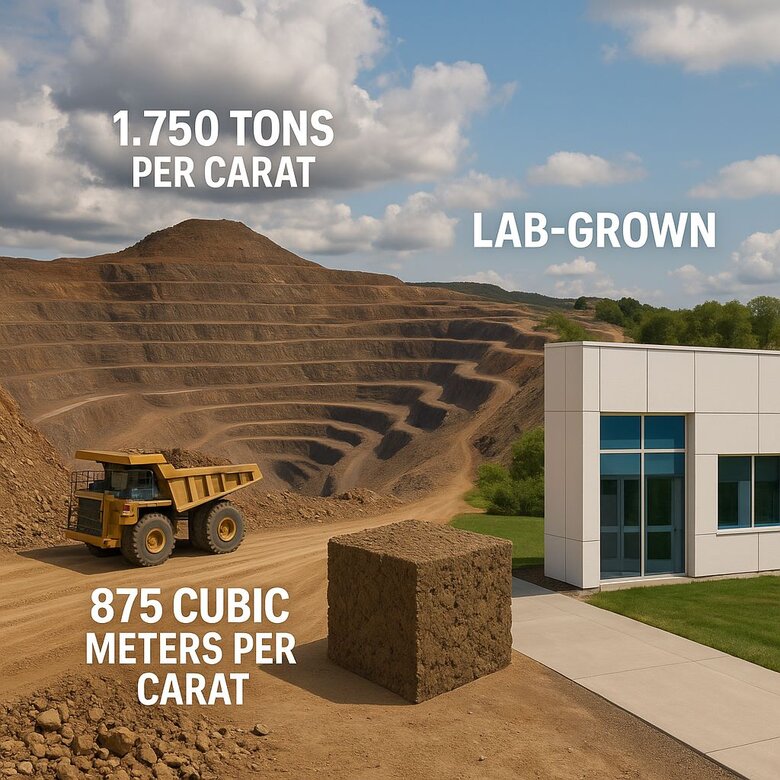

Lab grown diamonds require 25 times less earth excavation than mined diamonds. Zero mining disruption. This fundamental difference eliminates the massive environmental costs of traditional diamond extraction.

Traditional mining moves approximately 1,750 tons of earth per carat of gem-quality diamonds. That's enough material to fill 350 shipping containers. For one small stone.

Open-pit operations create craters spanning 2+ kilometers and reaching 400+ meter depths. Botswana's Jwaneng mine exemplifies this scale.

What's the alternative? CVD and HPHT facilities occupy less than 500 square meters while producing thousands of carats annually. The contrast resembles precision manufacturing versus strip-mining mountains.

| Environmental Factor | Lab-Grown Diamonds (per carat) | Mined Diamonds (per carat) | Environmental Impact Reduction |

|---|---|---|---|

| Earth Excavation | 0 tons | 1,750 tons | 100% reduction |

| Water Usage | 18 gallons | 126 gallons | 86% reduction |

| Land Disruption | 0.0007 sq meters | 98.5 sq meters | 99.9% reduction |

| Carbon Emissions | 0.028 tons CO2 | 0.57 tons CO2 | 95% reduction |

| Habitat Destruction | Zero wildlife displacement | 2.3 acres affected | 100% elimination |

| Energy Consumption | 250 kWh | 538 kWh | 54% reduction |

| Waste Generation | 0.1 kg industrial waste | 5,900 kg mining waste | 99.998% reduction |

| Chemical Processing | Controlled laboratory conditions | Heavy machinery oils, explosives | Eliminates toxic runoff |

How Much Earth Mining Moves Per Diamond Carat

Here's the staggering reality: 1,750 tons of earth moved per carat recovered. This stems from diamond concentrations of only 0.8-1.2 carats per ton in kimberlite deposits.

The scale becomes clear when visualized. One carat requires processing 875 cubic meters of earth - equivalent to a small building's foundation excavation.

Lab production? Complete elimination of earth disruption beyond standard industrial facility requirements.

Habitat Destruction from Traditional Diamond Mining Operations

Diamond mining fragments ecosystems by creating permanent industrial zones within intact habitats. Canada's Ekati Mine altered over 150 square kilometers of arctic tundra.

Marine operations off Namibia vacuum ocean floors at 150-meter depths. These remove entire benthic communities including slow-growing deep-sea corals.

Bottom line? Lab diamonds produce zero habitat impact during production. They operate within existing industrial zones, avoiding greenfield development entirely.

Biodiversity Impact Comparison Lab vs Mined Diamonds

Lab created diamonds generate zero direct biodiversity impact. Traditional mining creates permanent wildlife exclusion zones.

Congo Basin operations contributed to forest fragmentation affecting elephant migration routes. These mammals require continuous corridors spanning hundreds of kilometers.

CVD production occurs in sealed plasma chambers at 2000°C. No biological resources required. HPHT manufacturing similarly operates in closed systems replicating conditions 150 kilometers below Earth's surface.

Technical specifications complete? Yes. Environmental disruption? Zero.

"While traditional diamond mining disrupts vast tracts of land and depletes natural resources, lab-grown diamonds are produced with minimal environmental footprint. Our advanced CVD and HPHT methods not only avoid massive earth excavation but also significantly reduce carbon emissions per carat, demonstrating a sustainable future in diamond production."

CVD and HPHT Production Technology Environmental Benefits

Chemical Vapor Deposition and High Pressure High Temperature methods replicate natural diamond formation in controlled laboratories. No ecosystem extraction required.

These technologies represent precision manufacturing approaches creating identical chemical compositions without environmental disruption.

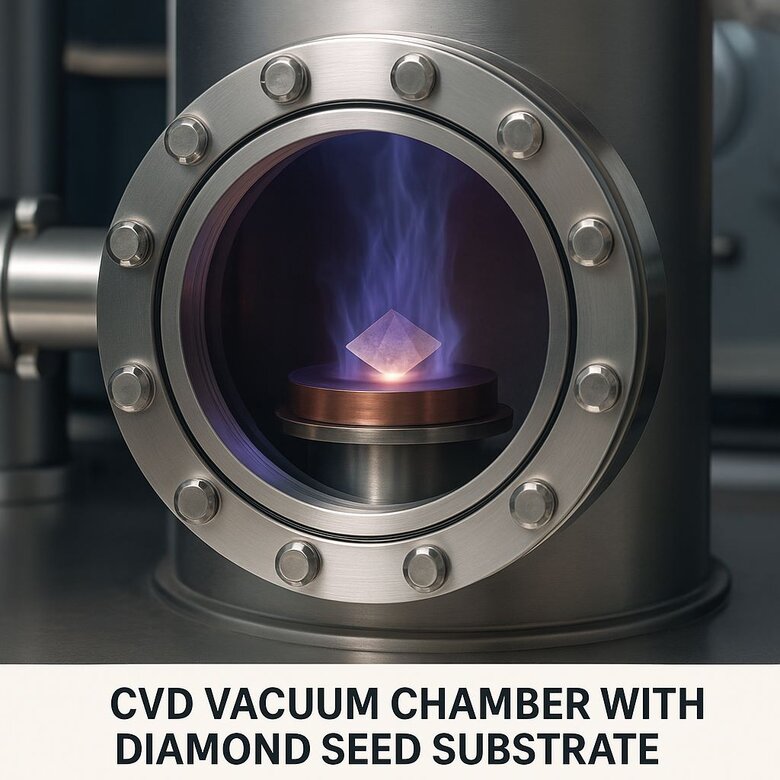

Chemical Vapor Deposition Controlled Laboratory Environment Benefits

CVD production occurs within vacuum chambers maintaining precisely controlled atmospheric conditions using methane and hydrogen gas feedstock. Pure Type IIA diamonds result.

Plasma chambers maintain 2000°C temperatures while processing carbon atoms into crystalline structures on diamond seed substrates. Microwave activation energizes gas feedstock, breaking molecular bonds for perfect crystalline arrangements.

The precision rivals semiconductor manufacturing. Atomic-level control produces consistent results batch after batch.

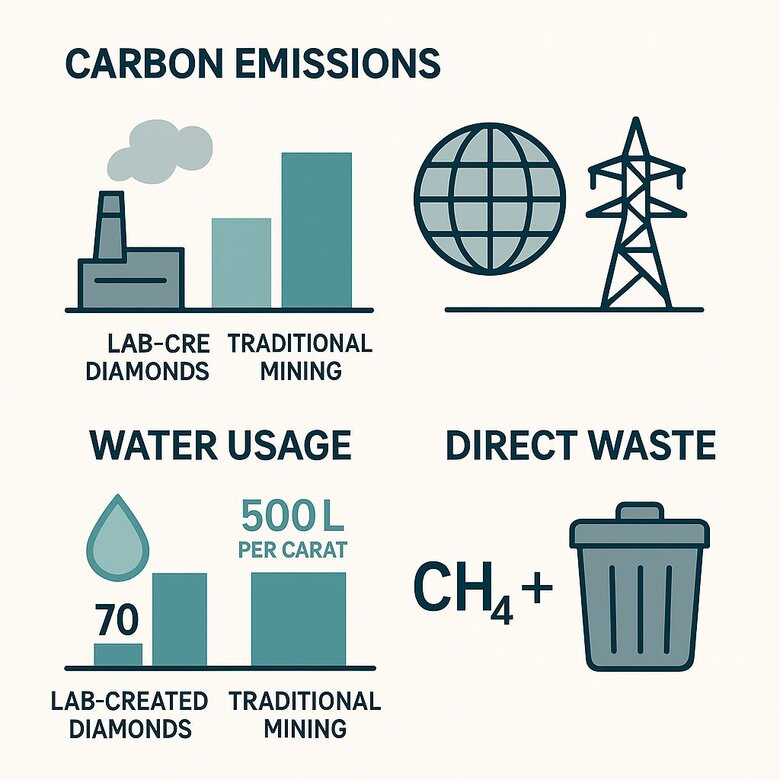

Water consumption averages 70 liters per carat, primarily for cooling systems. Traditional mining requires approximately 500 liters per carat including ore processing and dust suppression.

High Pressure High Temperature Manufacturing Carbon Footprint

HPHT diamond creation replicates conditions 150-200 kilometers below Earth's surface. It applies 5-6 GPa pressure at temperatures exceeding 1400°C within specialized chambers.

The process concentrates energy consumption within precise 3-5 day manufacturing windows. This contrasts sharply with mining operations maintaining continuous energy consumption across years.

Success rates exceed 95% for gem-quality production thanks to automated monitoring systems.

Here's the key difference: HPHT concentrates requirements within compact facilities rather than distributing impact across extensive mining operations and transportation networks.

SkyDiamond's Carbon-Negative Production

Traditional diamond production creates approximately 57 kg of CO2 emissions per carat through mining operations, transportation, and processing. Even conventional lab-grown diamonds using standard electricity grids generate 6-8 kg of CO2 per carat, still contributing to atmospheric carbon levels despite avoiding mining impacts.

SkyDiamond's facility in Stroud, UK operates entirely on renewable energy from wind and solar sources, while actively capturing atmospheric CO2 as the carbon feedstock for diamond creation. Their proprietary process uses direct air capture technology to extract CO2 from ambient air, then converts it into methane gas for the CVD diamond growing process. The facility removes 20 kg of CO2 from the atmosphere for every carat produced.

The facility achieves net-negative emissions of 20 kg CO2 per carat while producing 200 carats monthly (2,400 carats annually). This means SkyDiamond removes 48,000 kg of atmospheric CO2 yearly while generating premium Type IIA diamonds. Each diamond sold represents measurable atmospheric carbon reduction, transforming luxury jewelry into a climate-positive purchase that actively reverses previous carbon emissions.

Renewable Energy Powered Diamond Growing Facilities

Solar powered diamond production demonstrates compatibility between advanced manufacturing and renewable energy systems. Facilities in Israel achieve significant portions of energy requirements through photovoltaic systems.

The controlled nature allows precise energy demand forecasting. Unlike mining requiring continuous power for safety, diamond growing schedules around peak renewable generation periods.

Advanced systems monitor consumption throughout production cycles, optimizing growth schedules around solar availability. Battery storage provides backup while maximizing renewable utilization.

Geographic consideration? Solar integration performs optimally in consistent solar resource regions, though declining costs and improving storage expand viable locations continuously.

Third Party Certification and Sustainability Verification Systems

Independent certification bodies provide verified documentation through standardized testing protocols and supply chain auditing. No manufacturer self-reporting required.

The International Gemological Institute (IGI) maintains specific protocols documenting environmental impact including energy consumption monitoring and waste stream analysis. Their process requires detailed facility audits and ongoing compliance verification.

GIA provides grading services distinguishing lab created diamonds through advanced spectroscopic analysis. Reports include specific CVD and HPHT production method notations.

GCAL offers comprehensive sustainability reporting quantifying carbon emissions, water consumption, and energy source documentation. Their certification includes supply chain transparency extending to raw material sourcing.

What about conflict-free assurance? Kimberley Process exemption provides automatic compliance for lab created diamonds - they cannot originate from conflict regions by definition.

The trade-off involves certification costs and documentation complexity. But this provides verified environmental impact data enabling informed purchasing decisions.

| Certification Body | Sustainability Verification Protocol | Audit Requirements | Documentation Standards | Environmental Impact Measurement | Lab-Grown Diamond Specific Features |

|---|---|---|---|---|---|

| IGI (International Gemological Institute) | Comprehensive environmental impact documentation with energy consumption monitoring | Detailed facility audits every 18 months with ongoing compliance verification | ISO 14001 compliant reporting with waste stream analysis documentation | Energy usage tracking, carbon footprint calculation, waste reduction metrics | CVD/HPHT production method identification, lab origin verification, conflict-free certification |

| GIA (Gemological Institute of America) | Advanced spectroscopic analysis for lab-created diamond identification | Laboratory inspection every 24 months with equipment calibration verification | Standardized grading reports with production method notation | Limited environmental tracking, focus on identification and grading accuracy | Distinct CVD and HPHT notations on certificates, photoluminescence mapping |

| GCAL (Gem Certification and Assurance Lab) | Comprehensive sustainability reporting with quantified environmental metrics | Supply chain audits every 12 months extending to raw material sourcing | Triple certification with carbon emissions, water consumption, and energy source documentation | Complete carbon footprint analysis, water usage quantification, renewable energy percentage tracking | Lab-grown diamond purity verification, growth process documentation, sustainability score rating |

Carbon Emissions and Water Usage Technical Comparison

Lab created diamonds generate significantly lower carbon emissions per carat compared to traditional mining operations. Documented measurements show substantial reductions stemming from eliminated heavy machinery, transportation, and processing infrastructure.

Carbon footprint calculations include direct energy consumption during CVD or HPHT production plus indirect emissions from electricity generation. Renewable integration reduces indirect emissions proportionally.

Water usage presents another significant advantage. CVD production requires approximately 70 liters per carat compared to mining consuming around 500 liters per carat.

Why the difference? Laboratory water serves primarily cooling functions and recycles through closed-loop systems. Mining water includes ore processing, dust suppression, equipment cooling, and waste management across multiple stages.

CVD production generates minimal direct waste. Methane and hydrogen feedstock undergo complete consumption during crystallization. The controlled process produces only pure carbon crystals without tailings and waste rock.

Advanced instrumentation enables precise resource consumption measurement throughout production cycles. Real-time monitoring tracks energy, water, and waste with accuracy impossible across distributed mining operations.

Solar Powered Diamond Production and Future Sustainable Luxury

Solar powered diamond growing represents convergence of advanced manufacturing with renewable energy systems. Near-zero environmental impact while maintaining traditional quality and brilliance.

These installations prove environmental responsibility and luxury excellence are compatible, not competing values.

The controlled energy demand profile aligns optimally with solar generation characteristics. Diamond processes schedule during peak sunlight hours when photovoltaic systems generate maximum output.

Israel's facilities pioneered solar integration, utilizing consistent regional solar resources for CVD and HPHT systems. These demonstrate operational feasibility while achieving documented emission reductions.

Advanced energy management optimizes production schedules around solar forecasts, maximizing clean energy utilization while maintaining efficiency. Machine learning algorithms predict optimal timing based on weather patterns and availability.

Future sustainable luxury trends indicate growing consumer preference for documented environmental benefits, particularly among demographics prioritizing sustainability alongside quality and value.

The bottom line? Declining renewable costs and improving production efficiency create trajectory toward carbon-neutral luxury goods. Lab diamonds lead sustainable luxury markets through measurable environmental benefits aligning with evolving consumer values.

Verified Sustainability Meets Timeless Brilliance

Lab created diamonds deliver measurable environmental benefits through eliminated mining disruption, 86% water reduction, and renewable energy compatibility. Third-party certification ensures transparency while maintaining identical chemical composition and optical properties to mined stones.

Discover Your Perfect Eco-Friendly Diamond Today

Explore Labrilliante's certified sustainable collection featuring IGI-graded lab diamonds with documented environmental impact reports. Schedule your consultation to experience guilt-free luxury that aligns values with beauty.

Frequently Asked Questions

Yes, lab diamonds eliminate 99% of environmental impact by requiring zero mining excavation compared to 1,750 tons of earth moved per mined carat. They use 86% less water and can operate on renewable energy, while mining creates permanent 2+ kilometer craters and habitat destruction.

Lab diamonds require significant energy to reach 2000°C production temperatures, but their environmental impact depends heavily on the electricity source. Facilities using renewable energy or located in clean grid regions produce substantially lower emissions than coal-powered production or traditional mining operations.

Both CVD and HPHT methods operate in controlled laboratory environments with minimal environmental disruption, but CVD uses lower temperatures (2000°C) with plasma chambers while HPHT replicates deep earth conditions at higher pressures. Both consume around 70 liters of water per carat compared to mining's 500 liters.

Yes, facilities in regions like Israel successfully integrate solar power for significant portions of their energy needs. The controlled production schedules can align with peak solar generation hours, and advancing battery storage technology enables greater renewable energy utilization throughout production cycles.

Independent organizations like IGI, GIA, and GCAL conduct facility audits, monitor energy consumption, analyze waste streams, and provide documented environmental impact reports. These third-party certifications include supply chain transparency and ongoing compliance verification rather than manufacturer self-reporting.

This occurs when lab facilities operate in regions with coal-heavy electrical grids, particularly where renewable energy penetration is below 30%. However, unlike geographically constrained mines, lab facilities can relocate to renewable-rich regions or invest in dedicated clean energy systems.

Look for diamonds from facilities with renewable energy integration and third-party sustainability certification from IGI, GCAL, or similar bodies. Request environmental impact documentation and choose producers that provide transparent reporting on their energy sources and carbon footprint.

Many facilities are approaching carbon neutrality now through renewable energy integration and some like SkyDiamond already achieve carbon-negative production. As global renewable energy adoption accelerates and production efficiency improves, industry-wide carbon neutrality becomes increasingly achievable within the next decade.