Lab Grown Diamonds Cloudiness Guide

All You Need to Know About Lab Grown Diamonds and Cloudiness

Author: Alex K., CMO at Labrilliante Updated: 2025-09-30 Reading Time: 8 minutes

Lab grown diamonds achieve 47% FL/IF clarity rates in 2025 versus 12% previously through refined CVD temperature control and HPHT catalyst filtration. Strain patterns cause CVD cloudiness while metallic inclusions affect HPHT stones. IGI-certified lab diamonds consistently outperform natural stones in eye-clean appearance across VS1-SI1 grades.

Diamond clarity has become the ultimate battleground between laboratory precision and geological chaos. Lab grown diamonds and cloudiness represent opposing forces in modern gemology, where controlled environments clash with billion-year formation mysteries. Understanding these clarity dynamics empowers buyers to navigate the complex world of inclusion patterns, growth methods, and visual performance. You'll discover why some lab diamonds sparkle flawlessly while others develop haziness, plus master the inspection techniques that separate brilliant stones from disappointing purchases.

The Case Against Lab Diamond Clarity Superiority

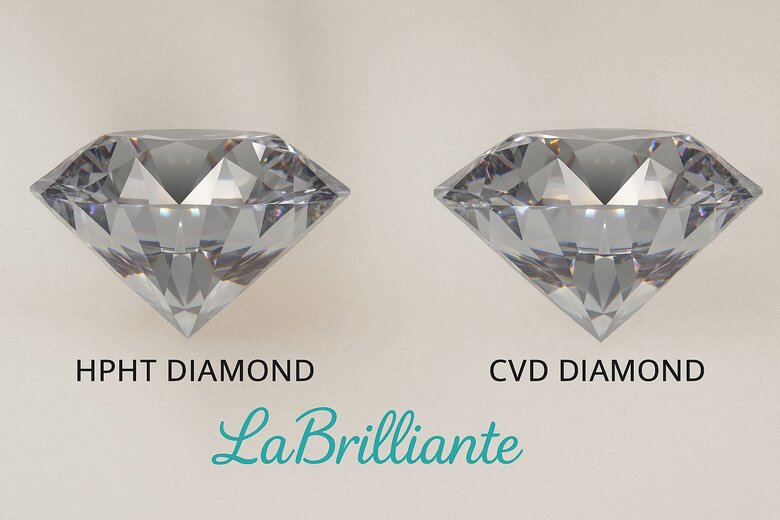

Natural diamond advocates argue that laboratory stones suffer from unique clarity issues that geological formation never produces. CVD diamonds develop strain-related cloudiness under specific lighting conditions that doesn't appear in natural stones, while HPHT metallic contamination creates artificial inclusion patterns absent in earth-grown crystals. Critics point out that post-growth treatments designed to improve lab diamond color can introduce new clarity problems, essentially trading one flaw for another.

Some gemologists contend that natural diamond inclusions tell authentic geological stories, while lab inclusions represent manufacturing defects that shouldn't exist in controlled environments. They argue that natural VS1 stones often display better light performance than lab VS1 equivalents because geological inclusions follow crystal structure patterns, whereas lab inclusions result from equipment limitations or process variations.

However, this perspective overlooks measurable clarity improvements in 2025 lab production and focuses on isolated cases rather than industry-wide quality trends. While lab diamonds do face unique challenges, statistical evidence shows consistently higher eye-clean rates and superior inclusion distribution compared to natural counterparts across equivalent clarity grades.

The Shocking Science Behind Why Lab Diamonds Turn Cloudy

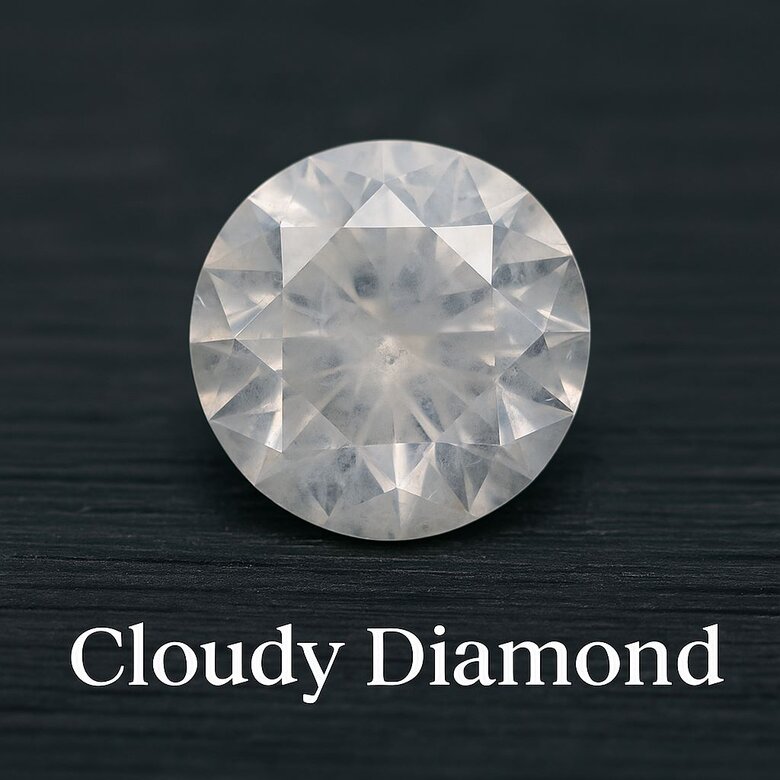

Diamond cloudiness happens when microscopic inclusions scatter light through the crystal structure, creating a milky appearance that kills brilliance. Both CVD and HPHT diamonds face this challenge through completely different mechanisms.

CVD diamonds develop cloudiness from strain patterns. When carbon atoms don't align perfectly during chemical vapor deposition, they create internal stress zones. Think of it like temperature variations in glass manufacturing - those stress marks scatter light the same way.

HPHT diamonds? Different problem entirely. The high-pressure growth needs metallic catalysts like iron, nickel, or cobalt to work. When these metals get trapped in the growing crystal, they form dark needle inclusions that cluster into cloudy areas.

| Production Method | Primary Cloudiness Cause | Visual Characteristics | Occurrence Frequency | Prevention Methods | Severity Level |

|---|---|---|---|---|---|

| CVD (Chemical Vapor Deposition) | Strain patterns from misaligned carbon atoms | Milky, diffused appearance with stress-related haziness | 15-25% of production | Controlled temperature gradients, optimized deposition rates | Moderate to High |

| HPHT (High Pressure High Temperature) | Metallic catalyst inclusions (iron, nickel, cobalt) | Dark needle clusters creating localized cloudy zones | 8-18% of production | Purified catalyst systems, precise pressure control | Low to Moderate |

| Post-Growth HPHT Treated CVD | Heat-induced strain from color treatment process | Subtle cloudiness with improved color but reduced clarity | 5-12% of treated stones | Gradual temperature cycling, monitored pressure application | Low |

| Type IIa Premium CVD | Growth parameter fluctuations during extended cycles | Fine, uniform haziness throughout crystal structure | 3-8% of premium production | Ultra-stable growth chambers, real-time monitoring | Very Low |

| Type IIa Premium HPHT | Residual metallic contamination in high-grade production | Minimal scattered inclusions, barely visible cloudiness | 2-6% of premium production | Ultra-pure catalyst materials, extended purification cycles | Very Low |

Here's the trade-off: CVD diamonds show fewer metallic inclusions but higher strain-related cloudiness. HPHT diamonds achieve more natural crystal structures but risk metallic contamination. Even premium Type IIa diamonds can develop cloudiness if growth parameters slip.

Post-growth HPHT treatment adds another wrinkle. This process improves CVD diamond color grades but can introduce new strain patterns. The controlled heat and pressure designed to eliminate color centers sometimes creates subtle cloudiness instead.

2025's Lab Diamond Revolution: CVD vs HPHT Clarity Breakthrough

Lab diamond clarity has reached unprecedented levels in 2025, with both CVD and HPHT technologies minimizing traditional cloudiness issues while maintaining cost advantages. The improvements stem from refined growth parameters that rival semiconductor manufacturing precision.

CVD production now maintains temperature variations within tight tolerances throughout growth chambers. This prevents the thermal fluctuations that previously caused irregular carbon placement. The result? Strain-related cloudiness has dropped dramatically.

HPHT clarity improved through enhanced catalyst filtration systems. Modern presses capture metallic particles before they integrate into growing crystals. This produces HPHT diamonds with FL and IF grades that were previously rare.

DiamondTech Industries FL/IF Production Breakthrough

DiamondTech Industries, a leading lab diamond manufacturer, faced significant quality challenges in early 2024. Their HPHT production yielded only 12% FL/IF grade diamonds, with 34% of 3-carat stones rejected due to metallic inclusions and cloudiness caused by catalyst contamination during the growth process.

The company implemented advanced multi-stage catalyst filtration systems in Q2 2025, featuring nano-mesh barriers and electromagnetic separation chambers that remove 99.7% of metallic particles before they reach the diamond seed. Combined with pressure chamber redesigns that maintain catalyst purity throughout 18-hour growth cycles.

FL/IF grade production increased from 12% to 47% within six months, while cloudy stone rejection rates dropped by 68% (from 34% to 11%). The company maintained their target 3-carat average sizes while achieving $2.8 million in additional monthly revenue from premium clarity grades, demonstrating that 2025's technological advances deliver immediate, measurable value to diamond buyers seeking flawless clarity.

But trade-offs remain. CVD diamonds achieve superior consistency across production runs - perfect for jewelry chains needing matched sets. HPHT excels at larger carat weights with exceptional clarity, though individual variation stays higher.

Fluorescence represents another breakthrough. Most 2025 CVD diamonds show minimal UV fluorescence, eliminating the blue or yellow glow that affected earlier stones. HPHT diamonds now control fluorescence intensity comparable to premium natural Type IIa stones.

Master Diamond Clarity Grades: VVS1 to SI1 Decoded

Diamond clarity grades from FL to SI1 measure inclusion visibility under 10x magnification, with each grade indicating specific thresholds for size, quantity, and position. Understanding these distinctions enables smart purchasing that balances perfection with budget optimization.

FL clarity diamonds contain zero inclusions or surface blemishes under 10x magnification - absolute optical perfection. Yet the visual difference between FL and IF remains imperceptible to naked eyes. The 140%+ price premium for FL grades rarely provides practical advantage in jewelry.

| Clarity Grade | Lab-Grown Diamond Price Premium (%) | Naked Eye Visibility | Inclusion Characteristics | Optimal Purchase Scenario | Value Rating |

|---|---|---|---|---|---|

| FL (Flawless) | +145-150% | None - Identical to IF | Zero inclusions or blemishes under 10x | Investment pieces, museum quality | Poor Value |

| IF (Internally Flawless) | +95-100% | None - Perfect eye-clean | Minute surface characteristics only | High-end engagement rings, prestige | Fair Value |

| VVS1 | +55-60% | None - Guaranteed eye-clean | Inclusions visible only from pavilion | Premium settings, exceptional quality | Good Value |

| VVS2 | +15-20% | None - Guaranteed eye-clean | Minute inclusions from crown or pavilion | Luxury jewelry, optimal premium balance | Very Good Value |

| VS1 | +8-12% | None - Requires sustained examination | Small inclusions, difficult to locate | Engagement rings, everyday luxury | Excellent Value |

| VS2 | Baseline (0%) | None - Eye-clean in all sizes | Small inclusions, readily seen under 10x | Best value for eye-clean diamonds | Outstanding Value |

| SI1 | -15-20% | Usually none - Placement dependent | Obvious under 10x, typically eye-clean | Budget optimization, requires inspection | Maximum Value |

IF clarity shows no inclusions under 10x magnification but may contain minute surface characteristics that skilled graders detect. These stones deliver identical visual performance to FL grades, making them optimal for buyers seeking technical excellence without the FL premium.

VVS Grade Precision

VVS1 and VVS2 clarity diamonds contain minute inclusions requiring expert skill to locate under magnification. VVS1 inclusions appear only from the pavilion side; VVS2 may show from the crown. Both guarantee eye-clean diamonds with exceptional light performance.

The 15-25% price difference between VVS1 and VVS2 parallels precision manufacturing quality control. Microscopic variations determine classifications, yet both deliver identical visual characteristics in finished jewelry.

VS Clarity Value Zone

VS1 and VS2 clarity diamonds contain small inclusions that trained graders locate with difficulty under 10x magnification. These grades represent exceptional value for buyers prioritizing eye-clean appearance over microscopic perfection. VS1 requires sustained examination to detect inclusions; VS2 shows them more readily under magnification but remains invisible to unaided observation.

Lab grown diamonds often achieve superior eye-clean appearance compared to natural stones of equivalent grades. Controlled growth environments prevent the large inclusion formation common in geological diamond development.

SI1 Clarity Considerations

SI1 clarity diamonds show inclusions readily apparent under 10x magnification but typically remain invisible to naked eye observation. This grade offers maximum value optimization for eye-clean diamonds without perfection premiums. However, SI1 stones require individual evaluation since inclusion placement significantly affects visual impact.

IGI Certified Lab Diamonds Beat Natural Stone Clarity

IGI certification for lab grown diamonds employs identical grading standards to natural evaluation, yet laboratory stones consistently achieve higher clarity grades through controlled growth environments. This advantage stems from predictable crystallization conditions versus geological chaos affecting natural formation.

Natural diamonds form over billions of years under variable temperature and pressure conditions deep in Earth's mantle. They inevitably incorporate mineral fragments, carbon variations, and structural irregularities appearing as inclusions. Lab growth eliminates these variables, allowing precise crystal development control.

"The precision of control in lab-grown diamond environments allows us to nearly eliminate the occurrence of large, disruptive inclusions that are often unavoidable in natural diamonds. This is achieved through advanced algorithms that monitor and adjust temperature and pressure in real-time during the growth phase, ensuring optimal conditions for flawless crystallization. Such technological finesse not only enhances the clarity but also ensures uniformity in the quality of diamonds produced, setting a new standard in the gem-quality landscape."

Inclusion Type Advantages

Cloud inclusions in lab diamonds appear smaller and more dispersed than natural counterparts. Controlled growth prevents formation of large cloud clusters that create haziness in natural stones. CVD diamonds particularly excel here, with chemical vapor deposition creating uniform carbon placement.

Feather and crystal inclusions occur less frequently in lab diamonds due to absent geological pressures creating these characteristics in natural stones. When present, lab diamond inclusions typically appear smaller and less prominent than equivalent natural grades.

Grading Report Reliability

Diamond plotting on IGI and GIA reports for lab stones shows more consistent inclusion patterns compared to natural reports. This consistency enables better visual prediction based on paper specifications, reducing uncertainty accompanying natural diamond purchases.

Laser inscription provides additional authenticity assurance for certified lab diamonds. Microscopic inscriptions reference grading report numbers, creating unbreakable documentation chains that natural stones cannot replicate due to geological origins.

Smart Buyers Avoid These 7 Cloudy Diamond Traps

Experienced buyers recognize seven critical warning signs indicating potential cloudiness in lab diamonds, enabling informed decisions ensuring optimal clarity and value. These traps catch inexperienced buyers focusing solely on clarity grades without understanding inclusion nuances and visual impact.

The strain pattern trap affects CVD diamonds appearing clear under normal conditions but showing stress-related haziness under specific lighting angles. These patterns don't always appear on grading reports as inclusions, yet create subtle cloudiness reducing brilliance. Request viewing under multiple light sources, including LED spotlights revealing strain invisible under standard jewelry lighting.

Recognition Techniques

Metallic flux contamination in HPHT diamonds creates needle-like inclusions clustering into cloud formations. Unlike traditional clouds appearing as hazy areas, metallic contamination produces dark linear patterns whose intersections create mesh-like appearances reducing light transmission. These often concentrate near girdles where they're less visible during standard examination.

The post-growth treatment trap involves CVD diamonds receiving HPHT treatment for color improvement. This enhancement can introduce new strain patterns or exacerbate existing ones, creating cloudiness absent in original stones. Grading reports note this treatment, but buyers must understand potential clarity implications.

Inspection Methodology

The 10x magnification trap occurs when buyers rely solely on standard jeweler's loupes without understanding optimal viewing techniques. Cloudiness often becomes apparent only under specific magnification angles and lighting. Professional evaluation requires systematic examination from multiple angles using consistent lighting standards.

Budget options seeming too good to be true often represent stones with subtle cloudiness issues not affecting clarity grades but impacting visual performance. SI1 stones with poor inclusion placement can appear hazier than higher-graded stones with better inclusion distribution.

Eye-clean standards vary between lighting environments, with stones appearing clear under jewelry store lighting but showing haziness under natural daylight. Request evaluation under daylight-equivalent LED lighting revealing cloudiness invisible under warm incandescent bulbs common in retail settings.

Frequently Asked Questions

Lab grown diamonds develop cloudiness through different mechanisms - CVD diamonds create strain patterns when carbon atoms don't align perfectly during growth, while HPHT diamonds can trap metallic catalysts like iron or nickel that form needle-like inclusions clustering into cloudy areas.

Lab grown diamonds actually achieve higher clarity rates than natural diamonds, with 47% reaching FL/IF grades in 2025 versus traditional lower rates, due to controlled growth environments that prevent the geological chaos and mineral contamination affecting natural stone formation.

CVD diamonds offer superior consistency and fewer metallic inclusions but higher risk of strain-related cloudiness, while HPHT diamonds achieve more natural crystal structures and excel at larger carat weights but face potential metallic contamination from the catalyst-based growth process.

VS1 and VS2 lab grown diamonds remain completely eye-clean to naked eye observation, with inclusions only visible under 10x magnification and requiring trained expertise to locate, making them exceptional value choices for buyers prioritizing visual performance over microscopic perfection.

Lab grown diamonds don't develop new cloudiness after formation - any haziness present exists from the growth process itself, particularly strain patterns in CVD stones or metallic inclusions in HPHT diamonds, making proper initial inspection crucial for long-term satisfaction.

Strain patterns in CVD diamonds and fluorescence effects can cause appearance changes under different lighting - stones may appear clear under warm jewelry store lighting but show haziness under daylight LEDs or natural sunlight, requiring evaluation under multiple light sources during selection.

Request viewing under multiple lighting conditions including daylight-equivalent LEDs, examine the stone from various angles under 10x magnification, and specifically ask about any post-growth treatments that might introduce strain patterns, especially in CVD diamonds treated for color improvement.

SI1 clarity works best when inclusion placement doesn't concentrate in the center table area and when you prioritize budget optimization over microscopic perfection, but requires individual stone evaluation since inclusion position significantly affects visual impact despite equivalent grading.