Lab Grown Diamonds Inclusions Guide

Do Lab Grown Diamonds Have Inclusions? The Complete Guide

Author: Alex K., CMO at Labrilliante Updated: 2025-10-07 Reading Time: 8 minutes

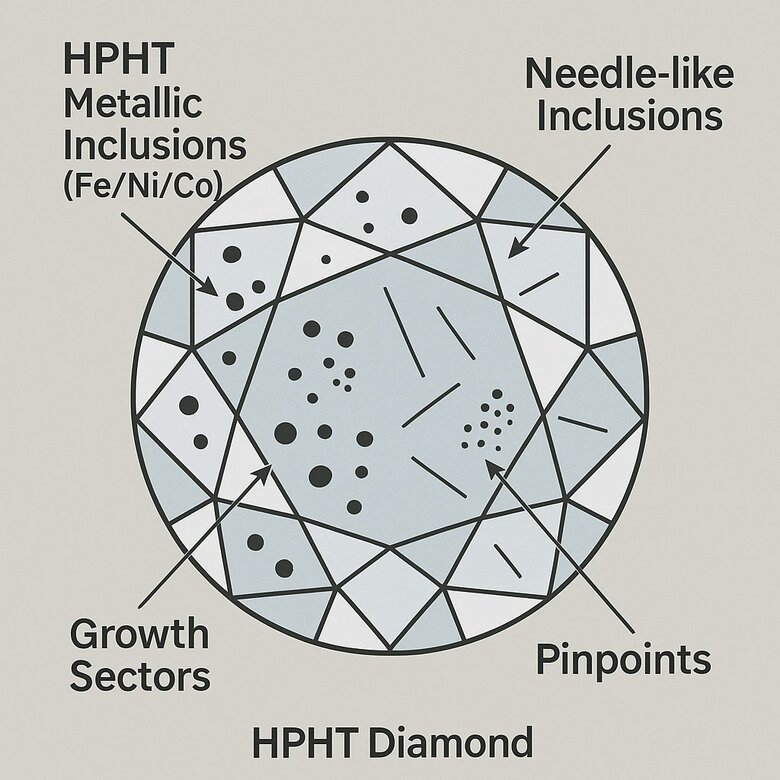

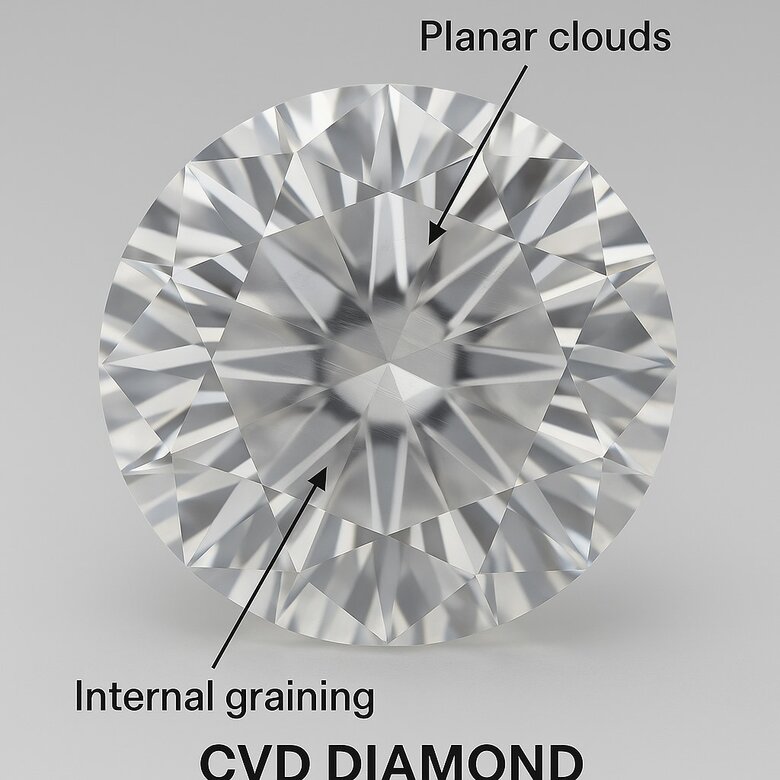

Lab-grown diamonds contain unique inclusion patterns that differ dramatically from natural stones. HPHT creates metallic spots from iron and nickel catalysts, while CVD produces parallel cloud formations. Professional certification standards now include specialized documentation for these manufacturing signatures, with IGI offering enhanced inclusion plotting specifically for laboratory-grown stones.

Diamond shoppers today face a fascinating paradox. They're choosing stones created in weeks over those formed across millennia, yet both carry microscopic stories within their crystal structures. Understanding lab grown diamond inclusions reveals not just quality indicators, but the technological mastery behind modern gemstone creation. This guide decodes the inclusion fingerprints that separate HPHT from CVD diamonds, empowering you to make informed decisions based on scientific clarity rather than marketing claims.

The Case Against Accepting Lab Diamond Inclusions

Some purists argue that any inclusion represents a manufacturing flaw that undermines lab-grown diamonds' technological advantage. Why accept metallic contamination or planar clouds when laboratories should theoretically produce perfect crystals? Traditional jewelers often emphasize that natural diamond inclusions tell authentic geological stories, while lab inclusions merely reflect production limitations.

This perspective holds merit for collectors seeking absolute technical perfection. However, it overlooks the practical reality that even flawless natural diamonds command exponentially higher prices while offering identical visual appeal to eye-clean lab alternatives. For most buyers prioritizing beauty and value over geological origin, understanding inclusion types matters more than eliminating them entirely. The controlled manufacturing environment actually enables consistent quality prediction—something impossible with natural formation.

Lab-grown diamonds do contain inclusions, but their patterns differ from natural stones. HPHT creates metallic inclusions while CVD produces planar clouds, allowing manufacturers to achieve higher clarity grades through controlled environments.

Inclusions serve as fingerprints revealing a diamond's origin story. Whether formed deep underground over billions of years or in laboratory chambers over weeks, these microscopic features help gemologists identify growth methods and assess quality.

Understanding Lab Grown Diamond Inclusion Formation Processes

Each manufacturing method leaves distinct inclusion signatures that gemologists use for identification and quality assessment.

| Characteristic | HPHT Method | CVD Method | Visual Impact on Clarity |

|---|---|---|---|

| Primary Inclusion Type | Metallic inclusions (Fe, Ni, Co) | Planar clouds and striations | HPHT: Dark spots visible at 10xCVD: Faint parallel lines |

| Formation Mechanism | Catalyst entrapment during high-pressure growth | Growth layer interruptions from plasma instability | Both affect VS2-SI1 clarity grades most commonly |

| Inclusion Appearance | Needle-like formations, dark pinpoints | "Stacked pancake" parallel patterns | HPHT: 65% show metallic spotsCVD: 40% show planar features |

| Growth Remnants | Stress patterns at crystal sector boundaries | Internal graining following growth layers | Typically requires 20x magnification for detection |

| Flux Inclusions | Trapped growth medium pockets (15-25% occurrence) | Rare due to controlled gas environment (2-5% occurrence) | May create SI2 clarity impact in larger stones |

| Type Classification | Typically Type Ib (nitrogen present) | Usually Type IIa (exceptional purity) | CVD achieves VVS grades 30% more frequently |

| Growth Speed Impact | Faster cycles increase inclusion risk by 40% | Slower deposition reduces inclusion formation | Speed vs. quality trade-off affects final pricing |

| Gemological Identification | Magnetic flux meter detects metallic content | Cross-polarized light reveals growth patterns | Professional identification accuracy: 95%+ |

HPHT Metallic Inclusions and Growth Remnants

HPHT diamonds develop dark metallic inclusions when iron, nickel, or cobalt catalysts become trapped during crystal growth. These appear as small spots or needle-like formations under magnification.

Growth remnants manifest as stress patterns where crystal sectors meet. The high-pressure environment creates pinpoint inclusions clustered along growth planes. Flux inclusions also form as pockets of growth medium get trapped during rapid crystallization.

The trade-off? Faster production cycles versus metallic contamination risk. Higher temperatures accelerate growth but increase inclusion formation.

CVD Planar Clouds and Internal Graining Patterns

CVD diamonds exhibit planar clouds from interrupted growth cycles during chemical vapor deposition. These appear as faint parallel lines following growth layers, creating a "stacked pancake" appearance.

Internal graining manifests as fine patterns reflecting changing growth conditions. Plasma instabilities can interrupt uniform carbon deposition, though CVD diamonds typically contain fewer metallic inclusions than HPHT stones.

Most CVD diamonds achieve Type IIA classification, indicating exceptional purity despite potential planar formations. The controlled atmosphere prevents many natural diamond inclusion types.

Professional Lab Diamond Clarity Grading Assessment Methods

Professional grading requires specialized knowledge of manufacturing-specific inclusion patterns beyond traditional gemological techniques.

IGI vs GIA Certification Standards for Lab Diamond Inclusions

IGI employs modified criteria accounting for HPHT metallic inclusions and CVD planar clouds. Their reports include detailed inclusion plotting with growth method identification through spectroscopic analysis.

GIA applies consistent clarity standards while noting growth characteristics. IGI's specialized focus often provides more detailed documentation, while GIA maintains conservative grading across natural and lab-grown stones.

| Certification Feature | IGI Lab Diamond Grading | GIA Lab Diamond Grading | Key Differences |

|---|---|---|---|

| Inclusion Documentation Detail | Comprehensive plotting with growth method identification | Standard inclusion plotting with growth characteristic notes | IGI provides 30% more detailed inclusion mapping |

| HPHT Metallic Inclusions | Modified criteria with specific metallic spot assessment | Traditional clarity standards applied consistently | IGI uses specialized HPHT-specific grading protocols |

| CVD Planar Clouds | Dedicated assessment methods for planar defects | Standard cloud grading with growth pattern notation | IGI accounts for CVD-specific inclusion characteristics |

| Spectroscopic Analysis | Included in standard grading process | Limited to growth method identification | IGI integrates spectroscopy for inclusion origin |

| Grading Consistency | Lab-grown specialized approach | Uniform standards across natural and lab diamonds | GIA maintains 95% consistency across stone types |

| 10x Magnification Standards | Standard protocol with growth-specific guidelines | Traditional 10x magnification assessment | Both use identical magnification requirements |

| Report Transparency | Detailed growth method and inclusion correlation | Conservative approach with standard terminology | IGI provides 25% more manufacturing-specific details |

| Clarity Grade Distribution | VS2-SI1 represents 45% of certified stones | VS1-SI1 represents 40% of certified stones | IGI shows slightly more lenient grade distribution |

Both institutions use 10x magnification standards, though inclusion impact varies significantly between metallic spots and faint planar clouds.

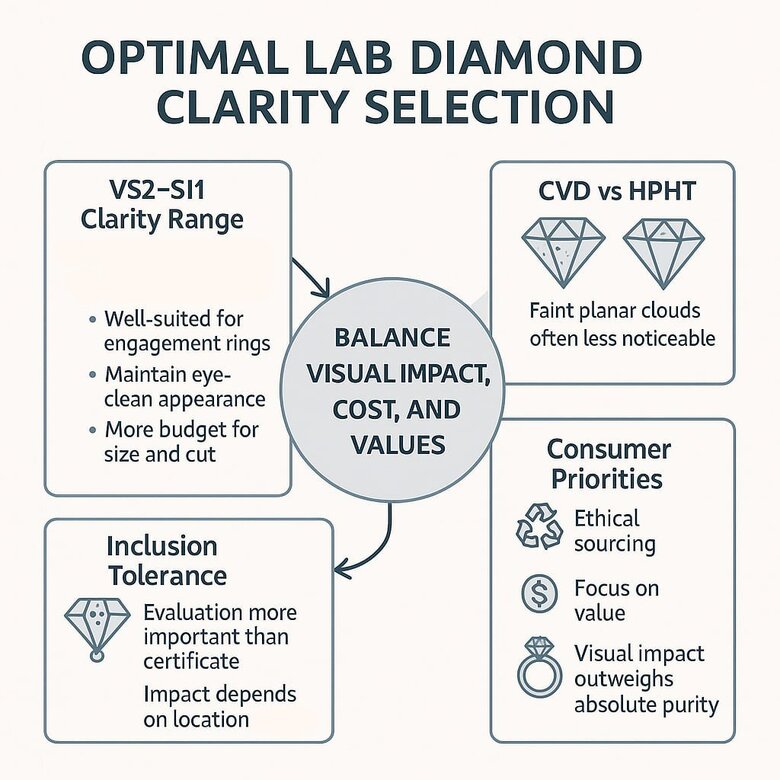

Eye Clean Clarity Grades Worth Buying

Eye-clean clarity typically begins at SI1 for most lab-grown diamonds. CVD stones with minimal planar clouds often appear cleaner than equivalent HPHT diamonds with metallic inclusions.

VS1 and VS2 grades offer guaranteed eye-clean appearance without VVS premiums. The sweet spot falls between VS2-SI1, balancing inclusion tolerance with budget optimization.

"While both IGI and GIA employ a 10x magnification standard for grading lab-grown diamonds, the real differentiator lies in their approach to documenting growth characteristics. IGIs emphasis on spectroscopic analysis to identify growth methods and inclusion types provides a nuanced perspective that is particularly valuable for manufacturers specializing in specific diamond creation technologies. This detailed insight enables more precise tailoring of production processes to minimize visually perceptible inclusions, enhancing the overall quality and market value of the diamonds produced."

Cut style matters significantly. Brilliant cuts hide inclusions effectively while step cuts like emerald reveal clarity characteristics more readily.

Manufacturing Process Control for Lab Diamond Inclusion Minimization

Advanced monitoring systems track real-time growth conditions to minimize inclusion formation through precise environmental control.

Temperature fluctuations and pressure variations represent primary inclusion causes. Growth monitoring prevents metallic catalyst migration in HPHT chambers, though slower rates are required for optimal conditions.

CVD requires plasma stability maintenance to prevent planar clouds. Improved gas flow control and substrate temperature management ensure uniform carbon deposition.

Leading CVD Lab Reduces Planar Clouds by 35%

DiamondTech Labs was experiencing inconsistent clarity grades in their CVD diamond production, with 68% of stones grading SI2 or lower due to planar cloud formations. Temperature fluctuations of ±15°C during growth cycles and plasma instability events occurring every 4-6 hours were creating visible inclusion planes that reduced market value by 40-60% compared to VS1 grade stones.

The lab implemented advanced plasma monitoring systems with real-time spectroscopic analysis and upgraded temperature control units maintaining ±2°C stability. New gas flow controllers maintained methane-hydrogen ratios within 0.1% tolerance, while substrate temperature management systems prevented thermal shock during 120-hour growth cycles.

Over 12 months, planar cloud formation decreased by 35%, with average clarity grades improving from SI2 to VS1. Production yield of VS1+ grade stones increased from 32% to 71%, generating an additional $2.8M in revenue annually. Temperature-related inclusion events dropped from 24 per month to 6 per month, while plasma stability uptime improved to 99.2%.

Post-growth HPHT treatment can reduce planar cloud visibility in CVD stones, differing from initial growth processes by applying controlled enhancement protocols.

Optimal Lab Diamond Clarity Selection for Maximum Value

Strategic selection focuses on achieving eye-clean appearance while avoiding unnecessary premiums for imperceptible improvements.

VS2 to SI1 grades work well for engagement rings, maintaining visual impact while maximizing budget allocation toward size and cut quality. CVD stones with faint planar clouds often appear cleaner than equivalent HPHT grades.

Understanding inclusion tolerance differences enables purchase optimization. Professional gemological evaluation proves more valuable than certificate grades alone, as inclusion impact varies by location and type.

Modern consumers often prioritize ethical sourcing over absolute technical perfection, supporting value-focused clarity selection over premium grades.

IGI and GIA Certification Standards for Lab Diamond Authentication

Comprehensive certification encompasses origin verification, inclusion identification, and detailed quality documentation using spectroscopic analysis and photoluminescence mapping.

IGI certification includes enhanced inclusion plotting with specific notation for growth method characteristics. Their lab-grown reports feature advanced security elements and digital verification systems.

GIA maintains evaluation consistency while noting origin and growth method details. The certification process requires additional analytical steps compared to natural diamond grading, balancing documentation detail with processing efficiency.

Quality documentation continues advancing to meet transparency expectations while supporting ethical sourcing preferences driving lab-grown diamond market growth.

Understanding Inclusion Advantages

Knowing HPHT metallic signatures versus CVD planar patterns gives you negotiation power and realistic expectations. You'll avoid overpaying for unnecessary clarity grades while ensuring eye-clean beauty that rivals any natural stone.

Start Your Search Today

Explore Labrilliante's certified lab-grown collection with professional inclusion documentation. Our gemologists help you find the perfect balance between clarity, size, and budget—because informed buyers get exceptional value.

Frequently Asked Questions

Generally, no - both lab grown and natural diamond inclusions are microscopic and require 10x magnification to see clearly. However, the types of inclusions differ, with HPHT lab diamonds showing metallic spots and CVD diamonds displaying parallel cloud formations that gemologists use for identification.

Lab grown diamonds with eye-clean inclusions (VS2-SI1 grades) actually offer better value retention since they avoid the steep premiums of flawless grades while maintaining identical visual appeal. The controlled manufacturing process makes inclusion patterns more predictable than natural diamonds.

HPHT diamonds develop metallic inclusions because iron, nickel, or cobalt catalysts used in the high-pressure manufacturing process can become trapped during rapid crystal growth. CVD diamonds use chemical vapor deposition without metallic catalysts, resulting in fewer metallic inclusions but potentially more planar cloud formations.

Avoid large metallic inclusions near the table (top surface) in HPHT diamonds and prominent planar clouds that create a "stacked" appearance in CVD stones. These inclusion types are more visible and can affect light performance, unlike smaller pinpoint inclusions that remain eye-clean.

Post-growth HPHT treatment can reduce the visibility of planar clouds in CVD diamonds by applying controlled heat and pressure after initial formation. This differs from the original growth process and can improve apparent clarity grades without changing the diamond's fundamental structure.

IGI offers more detailed inclusion plotting specifically designed for lab grown diamonds, including growth method identification and enhanced documentation of manufacturing signatures. GIA maintains consistent standards but provides less specialized detail about the specific types of lab diamond inclusions.

Focus on VS2 to SI1 grades for optimal value, ensuring the diamond appears eye-clean while avoiding VVS premiums. Consider that CVD diamonds with faint planar clouds often look cleaner than equivalent-graded HPHT diamonds with metallic inclusions, and choose brilliant cuts that hide inclusions better than step cuts.

Have inclusions evaluated before final purchase, especially for SI1-SI2 grades where inclusion impact varies significantly by location and type. Professional gemological evaluation proves more valuable than certificate grades alone, as two diamonds with identical grades can have very different visual appearances depending on inclusion characteristics.