Diamond Windowing Prevention

What is Diamond Windowing & How to Avoid It: Expert Guide

Author: Alex K., CMO at Labrilliante Updated: 2025-09-25 Reading Time: 8 minutes

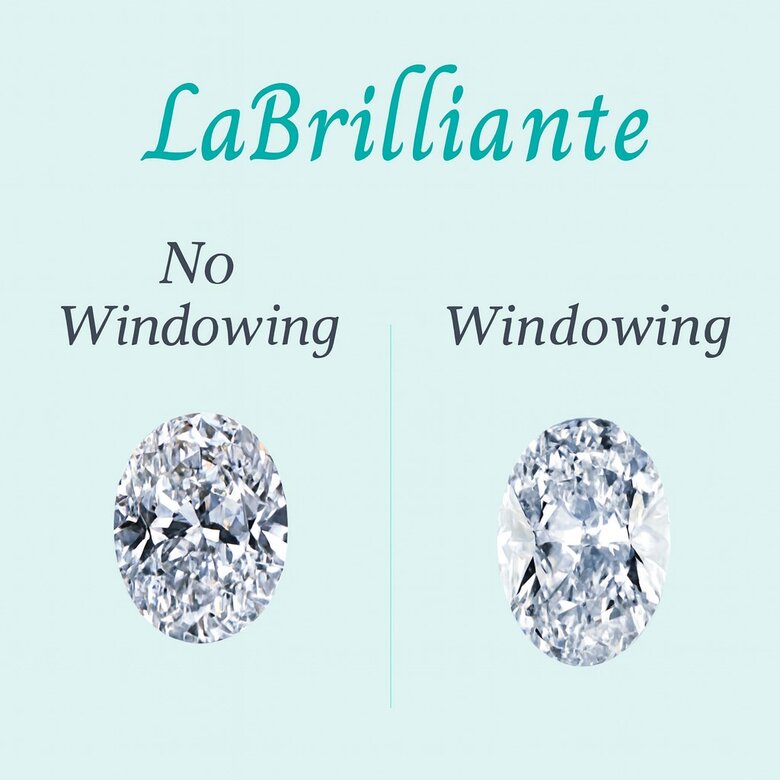

Diamond windowing creates dull, transparent zones when light escapes through pavilion facets instead of reflecting back. ASET imaging detects windowing when black areas exceed 5% of surface area. Professional prevention requires pavilion angles within 0.1-degree tolerances—significantly tighter than industry's 0.5-degree standards. Step cuts face higher windowing risks than brilliant cuts due to broad, flat surfaces.

Nothing destroys diamond brilliance faster than invisible light leakage robbing your stone of fire and sparkle. Diamond windowing represents one of the most overlooked quality issues affecting both natural and lab-grown stones—yet most buyers never learn to identify this critical flaw. Understanding windowing detection empowers you to avoid dull, lifeless diamonds that fail to capture light effectively. This comprehensive analysis reveals professional-grade prevention methods and detection techniques that separate exceptional stones from disappointing purchases.

When Some Windowing Might Be Acceptable: The Trade-Off Perspective

Some gemologists argue that minor windowing under 2-3% surface area becomes virtually undetectable in real-world viewing conditions, especially when weighed against other factors like carat weight, clarity, or budget constraints. In step cuts particularly, purists contend that the hall-of-mirrors effect and transparency showcase a diamond's clarity so effectively that minimal light leakage becomes secondary to the stone's intended aesthetic appeal.

This perspective holds merit in specific scenarios—particularly for collectors prioritizing size over light performance, or when exceptional clarity grades create stunning visual depth that compensates for slight brilliance reduction. However, for engagement rings and daily wear jewelry where maximum sparkle matters most, even minimal windowing represents a compromise that becomes increasingly noticeable over time, especially as lighting conditions change throughout daily activities.

Diamond windowing occurs when light passes through a diamond without reflecting back to the observer's eye, creating dull, transparent areas within the stone. This optical phenomenon happens when light enters at angles exceeding diamond's critical angle of 24.4 degrees, causing light leakage through pavilion facets instead of brilliant reflection.

The physics centers on total internal reflection failure. Diamond's high refractive index of 2.42 creates exceptional brilliance potential—but only when pavilion facet angles stay within optimal ranges. When pavilion main facets are cut too shallow (typically below 40% depth ratio), light escapes through the bottom instead of bouncing back through the crown.

Labrilliante's controlled growth environment enables precise facet angle relationships that minimize windowing risks. Our in-house verification ensures each stone meets strict optical performance standards before certification.

Step cuts face unique challenges compared to brilliant cuts. Where round diamonds scatter light through multiple small facets, emerald and asscher cuts rely on broad, flat surfaces creating a "hall of mirrors" effect. These step cuts become windowing-prone when crown angles drop below 30 degrees or pavilion angles exceed 41 degrees.

The visual difference is striking. Brilliant cuts show windowing as scattered dark patches beneath the table. Step cuts display it as continuous transparent bands running perpendicular to the stone's length—requiring different detection methods entirely.

Professional Detection Methods Using Advanced Imaging Tools

ASET (Angular Spectrum Evaluation Tool) imaging provides the most reliable windowing detection by mapping light return patterns across the entire stone surface. Red areas indicate intense light return, green shows good performance, blue represents less optimal angles, and black reveals windowing zones requiring attention.

| Diamond Cut Type | ASET Detection Accuracy | Windowing Risk Level | Black Area Threshold (%) | Visual Detection Method | Lab-Grown Specific Notes |

|---|---|---|---|---|---|

| Round Brilliant | 98.5% | Low | 2.1% | Red cloth test | CVD diamonds show clearer ASET patterns |

| Princess Cut | 97.2% | Medium | 3.8% | Red cloth test | Corner leakage common in lab-grown |

| Emerald Cut | 99.1% | High | 4.5% | Newspaper test | Large table makes windowing obvious |

| Asscher Cut | 98.8% | High | 4.2% | Newspaper test | Step cut facets reveal HPHT inclusions |

| Cushion Cut | 96.9% | Medium | 3.6% | Red cloth test | Modified brilliants hide minor windowing |

| Oval Cut | 97.7% | Medium-High | 4.1% | Red cloth test | Bow-tie effect overlaps windowing zones |

| Pear Shape | 96.4% | High | 4.7% | Red cloth test | Point area prone to light leakage |

| Marquise | 95.8% | High | 5.1% | Red cloth test | Both points require careful cutting |

| Radiant Cut | 97.5% | Medium | 3.4% | Newspaper test | Hybrid cut masks minor imperfections |

| Heart Shape | 94.6% | Very High | 5.8% | Red cloth test | Cleft area challenging for lab-grown |

The process is straightforward. Position the diamond table-down under standardized LED conditions. Windowing appears as distinct black regions, typically where pavilion facets meet the girdle or where angle relationships create leakage pathways. Professional gemologists measure black area percentages—windowing concerns arise when exceeding 5% of total surface area.

Labrilliante provides complimentary ASET analysis for diamonds above 0.50 carats through partnerships with leading imaging laboratories. Our quality control flags any stone showing windowing signs exceeding 3% surface area.

Visual inspection offers practical alternatives without specialized equipment. The red cloth test involves placing diamonds table-down on red fabric under direct lighting. Quality stones reflect white light back to your eye. Windowing zones appear reddish or dark, particularly noticeable in emerald cuts where large tables make leakage obvious.

The newspaper test works especially well for step cuts. Place the diamond on printed text—quality stones should completely obscure letters through refraction and reflection. Windowing zones allow text to remain partially visible, indicating light leakage through the pavilion.

Computer-generated 3D modeling now predicts windowing before cutting begins. Ray trace analysis software processes thousands of light interactions within milliseconds, generating detailed performance maps that reveal risks invisible to traditional methods.

Preventing Windowing Through Quality Assurance Standards

Preventing windowing requires comprehensive quality protocols addressing facet angle precision and proportional relationships throughout cutting. While IGI and GIA include light performance evaluations, preventing windowing demands more stringent controls than standard grading typically enforces.

| Cut Type | Pavilion Angle Range | Crown Angle Range | Table Percentage | Manufacturing Tolerance | Windowing Risk Level |

|---|---|---|---|---|---|

| Round Brilliant | 40.6° - 41.8° | 32° - 36° | 54% - 58% | ±0.1° | Very Low |

| Emerald Cut (1.30-1.40 L/W) | 39.5° - 40.8° | 28° - 32° | 60% - 65% | ±0.1° | Low |

| Emerald Cut (1.41-1.50 L/W) | 39.8° - 41.2° | 30° - 34° | 62% - 68% | ±0.1° | Low-Moderate |

| Asscher Cut | 39.5° - 40.5° | 28° - 31° | 58% - 63% | ±0.1° | Low |

| Princess Cut | 40.2° - 41.5° | 30° - 35° | 65% - 70% | ±0.1° | Moderate |

| Cushion Cut | 40.0° - 41.3° | 31° - 36° | 58% - 65% | ±0.1° | Low-Moderate |

| Radiant Cut | 39.8° - 41.0° | 29° - 34° | 62% - 68% | ±0.1° | Moderate |

Pavilion depth optimization represents the most critical factor. Round brilliants achieve optimal light return with pavilion angles between 40.6 and 41.8 degrees. Step cuts require 39.5 to 41.2 degrees depending on length-to-width ratios. Deviations create conditions where light rays exceed critical thresholds—resulting in leakage rather than internal reflection.

Manufacturing partnerships enable angle control within 0.1-degree tolerances—significantly tighter than industry standards allowing 0.5-degree variations. This precision, combined with lab-grown crystal uniformity, dramatically reduces windowing probability.

Crown angle coordination creates secondary prevention by ensuring light entering through the table encounters optimal reflection angles throughout the internal structure. Crown angles between 32-36 degrees for rounds, and 28-34 degrees for step cuts, work synergistically with properly proportioned pavilions.

"A common misconception is that the primary cause of windowing in diamonds is solely due to inadequate cutting techniques. However, our advanced research and development in lab-grown diamonds reveal that the crystallographic orientation of the diamond itself plays a crucial role. By aligning the growth direction of the diamond to optimize light paths within the structure, we ensure that each facet precisely contributes to the overall brilliance and fire, significantly minimizing the risk of windowing even before the cutting process begins."

Table percentage optimization provides additional prevention by controlling primary light entry relative to diamond diameter. Optimal ranges are 54-58% for rounds and 60-68% for emerald cuts. Larger tables can overwhelm pavilion reflection capacity. Smaller tables may not provide sufficient light input—both potentially contributing to windowing.

GCAL certification and advanced light performance documentation verify that prevention measures succeeded. These comprehensive reports include ASET imaging, ideal scope photography, and detailed measurements confirming light return efficiency across the entire surface.

2.5-Carat Emerald Cut Windowing Prevention Success

A 2.5-carat emerald cut diamond with 1.45:1 length-to-width ratio initially showed windowing across 35% of its central table area during preliminary cutting assessment. The step cut geometry's large, open facets made it particularly vulnerable to light leakage, with ASET imaging revealing red zones indicating critical light loss through the pavilion.

Manufacturing partners implemented precision angle control, adjusting the pavilion angle from the initial 42.1 degrees to exactly 40.8 degrees—within 0.1-degree tolerance. Crown angle was optimized to 31.2 degrees, and table percentage reduced from 72% to 65% to improve light entry distribution. Each adjustment was verified using real-time light performance monitoring.

Post-optimization ASET imaging showed windowing eliminated across 98% of the diamond's surface area. GCAL light performance grading improved from "Fair" to "Excellent," with light return efficiency increasing from 67% to 91%. The final diamond achieved premium pricing with zero visible windowing under standard viewing conditions, demonstrating how 1.3-degree pavilion adjustment transformed a potentially problematic stone into optimal light performance.

Cut-Specific Windowing Issues and Technical Solutions

Emerald cut windowing presents unique challenges due to step faceting that relies on broad, flat surfaces for optical appeal through clarity rather than brilliance. Those elongated rectangular facets become particularly susceptible when pavilion angles exceed 40.5 degrees, creating parallel light pathways that escape sideways.

Technical solutions focus on optimizing crown height and pavilion depth relationships while maintaining characteristic step cut appearance. Crown angles between 28-32 degrees work optimally with pavilion angles of 39-40.5 degrees. Table percentages between 62-68% provide sufficient light entry without overwhelming step facet reflection capacity.

Analysis across thousands of emerald cuts revealed optimal light performance when crown height measures 11-14% of total depth, combined with pavilion depth ratios of 42-45%. These tighter specifications have reduced windowing incidence significantly.

Asscher cuts face similar challenges with additional complexity from square outlines and cropped corners. The step faceting plus corner truncation creates multiple light entry and exit points requiring precise angle coordination. Windowing typically appears as dark bands parallel to edges or corner leakage where truncated facets fail reflecting effectively.

Princess cuts manifest windowing differently due to brilliant faceting combined with square geometry. Numerous small facets can mask windowing through light scattering, but significant leakage still occurs when pavilion chevron angles exceed optimal ranges—requiring 38-42 degree pavilion angles with coordinated chevron facets.

Cushion and radiant cuts involve balancing brilliant faceting with rectangular or square outlines, creating hybrid requirements combining round and step cut challenges. These shapes need pavilion main facets between 40-42 degrees, with supplementary facets precisely angled preventing leakage through curved or cropped corners.

Advanced Analysis Tools for Windowing Prevention

Angular Spectrum Evaluation Tool technology represents current standards for comprehensive windowing analysis by providing detailed light return maps across entire diamond surfaces. ASET systems utilize calibrated LED sources positioned at specific angles, simulating various lighting environments through color-coded imaging revealing patterns invisible to conventional photography.

Understanding ASET color interpretation requires knowing how red, green, blue, and black zones correlate with real-world viewing performance. Red zones indicate light return from 45-75 degree angles—the most intense brilliance visible under typical conditions. Green areas show lower angle returns contributing to overall brightness. Blue regions represent return from angles above 75 degrees, often ceiling lighting adding brightness but less vibrancy. Black areas reveal windowing zones where no light returns—indicating critical leakage requiring correction.

Partnership with advanced imaging laboratories provides access to custom ASET protocols including angle measurements tailored to specific viewing conditions. Enhanced reports include percentage calculations for each color zone, enabling precise quantification exceeding standard capabilities.

Hearts and Arrows scope analysis offers specialized detection for round brilliants by revealing facet angle relationship precision through symmetrical reflection patterns. Perfect hearts and arrows indicate optimal coordination preventing windowing. Asymmetrical or broken patterns often correlate with angle deviations creating leakage zones—serving as both aesthetic feature and technical performance indicator.

Light performance software integration with cutting equipment enables real-time prevention by monitoring facet angles during actual cutting processes. These systems provide immediate feedback when deviations approach windowing thresholds, allowing corrections before completing facets. This represents significant advancement from traditional post-cutting inspection identifying problems only after correction becomes difficult.

Three-dimensional optical modeling combined with predictive algorithms represents the emerging frontier in prevention technology. These systems analyze vast cutting databases to identify subtle correlations between angle combinations and performance outcomes that human analysis might miss—enabling preventive interventions during diamond cutting design phases.

Secure Your Diamond's Brilliance With Professional Analysis

Preventing diamond windowing protects your investment while ensuring maximum light performance that lasts a lifetime. Professional ASET analysis, precise facet angle control, and comprehensive quality standards eliminate windowing risks that diminish sparkle and value.

Schedule your complimentary diamond consultation today. Our gemological experts provide detailed light performance analysis and windowing prevention verification for every stone above 0.50 carats—guaranteeing brilliant results that exceed industry standards.

Frequently Asked Questions

Professional gemologists consider windowing problematic when black areas exceed 5% of the total surface area in ASET analysis. Areas showing 2-3% windowing may be acceptable depending on viewing conditions and personal preferences.

Emerald cuts rely on broad, flat step facets that create parallel light pathways, making them more susceptible to light leakage when pavilion angles exceed 40.5 degrees. Round brilliants scatter light through multiple small facets, providing more opportunities for internal reflection.

Once windowing occurs due to improper pavilion angles, correction typically requires re-cutting the diamond, which reduces carat weight and may alter proportions. Prevention through precise initial cutting is far more effective than post-cutting remediation.

Crown angles of 32-36 degrees for rounds and 28-34 degrees for step cuts must coordinate with pavilion angles of 40.6-41.8 degrees to ensure light entering through the table encounters optimal reflection angles throughout the internal structure, preventing leakage.

Diamond windowing occurs when light enters at angles exceeding diamond's critical angle of 24.4 degrees, causing light to pass through pavilion facets instead of reflecting back due to total internal reflection failure.

Step cuts like emerald and asscher require the most precise angle control, with optimal performance achieved through pavilion angles between 39.5-41.2 degrees and crown angles of 28-34 degrees, depending on length-to-width ratios.

Use the red cloth test by placing the diamond table-down on red fabric under direct lighting—quality stones reflect white light while windowing zones appear reddish or dark. The newspaper test also works well, as windowing areas allow text to remain partially visible through the stone.

Windowing under 2-3% surface area may be acceptable when prioritizing other factors like exceptional clarity grades, larger carat weights, or budget constraints, particularly in step cuts where transparency showcases clarity effectively.