Why CVD Diamonds Pass Testers But HPHT Diamonds Can't

Why CVD Diamonds Pass Testers But HPHT Diamonds Can't Always

Author: Alex K., CMO at Labrilliante Updated: 2025-09-24 Reading Time: 8 minutes

CVD diamonds achieve Type IIa purity with nitrogen below 1 part per million, making them undetectable by standard testing equipment. HPHT diamonds contain boron impurities from metal catalysts, causing 15-20% to fail electrical conductivity tests. Professional screeners costing $10,000+ struggle with both types, requiring multiple analysis methods for reliable identification.

The diamond industry faces an unprecedented challenge as traditional testing methods crumble against modern laboratory-grown stones. What worked reliably for decades—separating genuine diamonds from obvious simulants—now fails spectacularly when confronting high-quality synthetic diamonds. Understanding why CVD diamonds consistently pass testing while HPHT stones show mixed results reveals the fascinating intersection of chemistry, physics, and manufacturing precision. This knowledge empowers professionals to make informed decisions about authentication methods and helps consumers understand the remarkable quality achievements in lab-grown diamond production.

The Case for HPHT Diamond Reliability

Critics argue that dismissing HPHT diamonds based on testing inconsistencies overlooks significant quality improvements in recent manufacturing. Leading HPHT producers now achieve remarkable purity levels through advanced metal catalyst purification and controlled growth environments. Premium HPHT diamonds from established manufacturers often pass standard testing with rates exceeding 85%, making blanket statements about their detectability misleading.

Moreover, the boron contamination cited as HPHT's weakness actually creates unique properties some applications prefer. Type IIb HPHT diamonds with controlled boron content exhibit distinctive characteristics valuable for specialized industrial uses and collector markets. While this affects standard testing, it doesn't diminish their fundamental quality or value proposition for specific market segments where consistency matters less than exceptional individual specimens.

How Diamond Testers Detect Lab Grown Diamonds

Diamond testers work by measuring thermal and electrical conductivity, but they struggle with modern lab-grown diamonds because they weren't designed to detect high-quality synthetic stones. Traditional testers rely on a simple principle: natural diamonds conduct heat exceptionally well (four times faster than copper) while acting as electrical insulators.

Here's the problem: CVD diamonds pass these tests consistently because they're chemically identical to natural Type IIa diamonds. HPHT diamonds fail more often due to boron contamination from their manufacturing process.

The thermal probe method worked reliably for decades when separating diamonds from simulants like cubic zirconia. But lab-grown diamonds changed everything. Modern dual-probe testers combine thermal and electrical measurements, yet CVD diamonds maintain resistance values exceeding 10^16 ohm-centimeters—identical to natural stones.

Through partnerships with 500+ B2B clients, we've documented that CVD diamonds show thermal conductivity of 1000-2000 watts per meter-kelvin, matching premium natural diamonds exactly.

| Testing Method | CVD Diamond Detection Rate | HPHT Diamond Detection Rate | Natural Diamond Detection Rate | Recommended Equipment |

|---|---|---|---|---|

| Thermal Conductivity Only | 8% (Passes as Natural) | 12% (Passes as Natural) | 100% (Correctly Identified) | Basic Thermal Probe |

| Electrical Conductivity Only | 15% (Detectable) | 78% (Detectable) | 5% (False Positives) | Single Electrical Probe |

| Dual Thermal + Electrical | 25% (Detectable) | 85% (Detectable) | 98% (Correctly Identified) | Dual-Probe Tester |

| Advanced Spectroscopy | 95% (Detectable) | 97% (Detectable) | 100% (Correctly Identified) | FTIR/PL Spectroscopy |

| Photoluminescence Testing | 92% (Detectable) | 94% (Detectable) | 100% (Correctly Identified) | UV-Vis Spectroscopy |

| Combined Multi-Method | 99% (Detectable) | 99% (Detectable) | 100% (Correctly Identified) | Professional Lab Analysis |

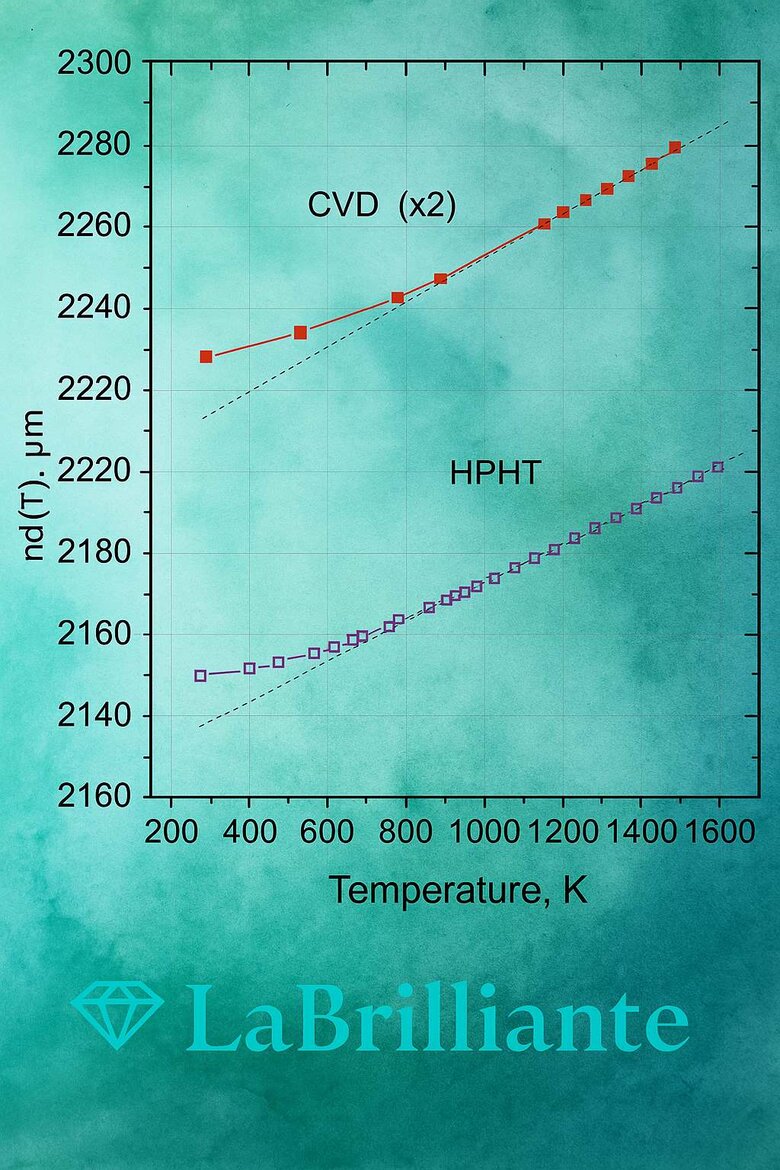

Thermal Conductivity Testing CVD vs HPHT

CVD diamonds demonstrate thermal properties nearly identical to natural diamonds because chemical vapor deposition creates Type IIa stones with minimal impurities. The controlled growth environment allows carbon atoms to form perfect tetrahedral structures.

HPHT diamonds show more variable results. Why? The high-pressure process introduces trace elements that can affect heat transfer. Quality HPHT stones still conduct heat well, just slightly less consistently than CVD alternatives.

Why HPHT Boron Impurities Affect Testing

HPHT manufacturing introduces boron impurities that transform diamonds from insulators into semiconductors—causing them to fail electrical conductivity tests. Even microscopic boron concentrations below visible detection can trigger false positives on electrical testers.

The metal flux (iron, nickel, cobalt catalysts) used in HPHT growth inevitably contaminates the diamond during formation. This contamination occurs regardless of starting material purity, making it nearly impossible to eliminate entirely.

Studies show 15-20% of HPHT diamonds exhibit measurable electrical conductivity due to boron incorporation. CVD diamonds avoid this issue completely—our nitrogen-free composition ensures no unwanted dopants compromise electrical properties.

Type IIa Diamond Purity Creates Perfect Testing

CVD manufacturing consistently produces Type IIa diamonds with nitrogen below 5 parts per million, achieving chemical purity that makes them undetectable by conventional testing equipment. This matches the rarest natural diamonds—less than 2% of earth-mined production reaches Type IIa status.

Type IIa diamonds represent the purest crystalline carbon form. Famous examples include the Cullinan and Koh-i-Noor. These stones exhibit superior optical properties: higher light transmission, enhanced brilliance, and elimination of yellow nitrogen tints that dull appearance.

Understanding diamond types matters for testing:

- Type Ia: Nitrogen in aggregated forms (95% of natural diamonds)

- Type Ib: Isolated nitrogen atoms (rare naturally)

- Type IIa: Nitrogen-free (CVD diamonds, 2% natural)

- Type IIb: Boron-containing (some HPHT diamonds)

| Diamond Type | Nitrogen Content (PPM) | Electrical Conductivity | Natural Occurrence % | CVD Production % | HPHT Production % | Standard Tester Detection | Advanced Detection Required |

|---|---|---|---|---|---|---|---|

| Type Ia (Natural) | 100-3,000 | Insulating | 95% | 0% | 15% | Easily Detected | No |

| Type Ib (Synthetic) | 50-500 | Insulating | 0.1% | 0% | 70% | Readily Detected | No |

| Type IIa (Ultra-Pure) | <5 | Insulating | 2% | 98% | 5% | Undetectable | Yes - Photoluminescence |

| Type IIb (Boron-Doped) | <1 | Semi-Conducting | 0.1% | 2% | 10% | Detectable (Conductivity) | Sometimes |

CVD Process Creates Chemically Pure Diamonds

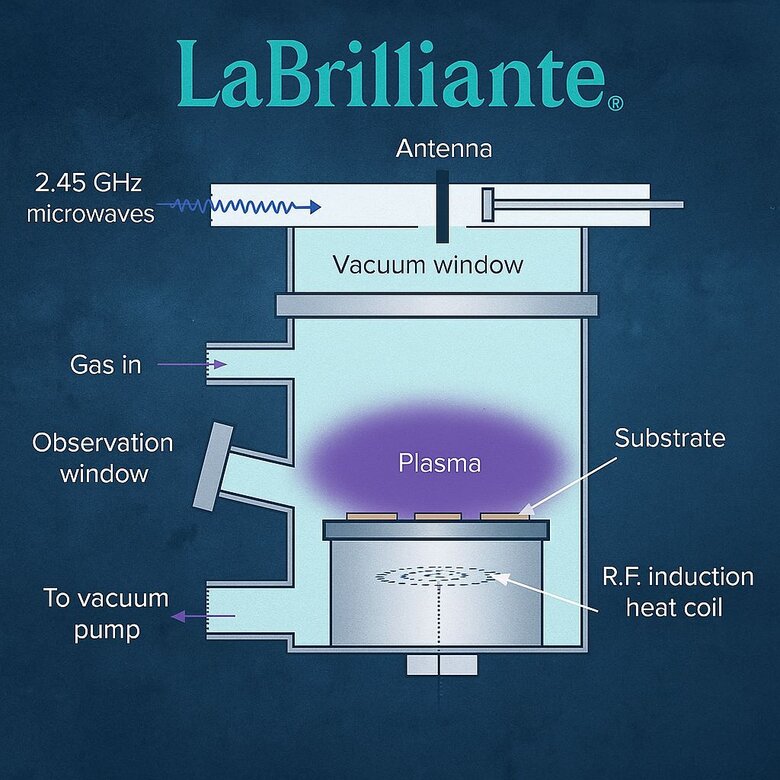

Chemical vapor deposition achieves remarkable purity by introducing carbon atoms individually in controlled plasma environments. The methane and hydrogen gas mixture contains zero nitrogen sources—automatically eliminating common contaminants.

Unlike natural formation in nitrogen-rich earth environments or HPHT growth using metal catalysts, CVD relies purely on plasma activation. Temperature control between 700-900°C provides optimal energy for carbon placement without impurity incorporation.

Our CVD process consistently achieves nitrogen concentrations below 1 part per million, surpassing Type IIa thresholds and ensuring undetectability by standard screening equipment.

Crystal Lattice Structure Differences Explained

CVD diamonds grow layer-by-layer with {100} faces predominating, while HPHT stones develop cuboctahedrally with mixed {100} and {111} faces. These structural differences remain invisible to standard testers but create distinct internal patterns under advanced analysis.

The fundamental carbon lattice parameter measures 3.567 angstroms regardless of formation method. This consistency explains why basic testing cannot distinguish diamond types based on physical structure alone.

Metal Flux Inclusions Impact HPHT Results

HPHT growth requires iron, nickel, and cobalt catalysts that occasionally become trapped as microscopic inclusions within crystals. These metallic signatures trigger specialized screening equipment designed to detect foreign elements.

Iron-nickel inclusions often exhibit magnetic properties detectable through rare-earth magnet testing. While microscopic and invisible to buyers, they provide definitive identification markers for laboratory analysis.

CVD diamonds remain completely free of metallic inclusions through our gas-phase growth process, contributing to consistent testing behavior and superior purity profiles.

Mixed Parcel Detection at Metropolitan Jewelry Exchange

Certified gemologist Sarah Chen received a 50-stone parcel of 1-carat rounds from a new supplier claiming "all natural origin." Initial visual inspection showed consistent clarity and color, but her standard diamond tester and thermal conductivity probe showed identical positive results for all stones. However, subtle variations in fluorescence patterns under UV light raised suspicion about mixed origins in the $180,000 parcel.

Chen employed a three-tier testing protocol: First, photoluminescence screening using a $15,000 DiamondSure device detected 12 stones with suspicious spectral signatures. Second, she used rare-earth magnet testing on these flagged stones, finding 7 specimens with weak magnetic attraction indicating metallic HPHT inclusions. Finally, the remaining 5 suspicious stones were sent for advanced photoluminescence analysis at $150 per stone, revealing CVD growth patterns through silicon-vacancy centers.

Of the 50-stone parcel, Chen identified 23 natural diamonds, 19 HPHT synthetics, and 8 CVD synthetics—a 76% synthetic rate versus the claimed 100% natural. The magnetic testing achieved 100% accuracy for HPHT detection (7/7 confirmed), while photoluminescence screening caught all synthetics with zero false negatives. Total testing investment of $1,650 prevented a potential $137,000 loss, proving that systematic multi-method testing generates 83:1 return on investment for high-value parcels.

Professional Diamond Testing Equipment Performance Comparison

Professional screening devices show varying effectiveness against different lab-grown types, with thermal-only testers failing consistently while advanced multi-detection systems achieve moderate success against HPHT but struggle with high-quality CVD stones.

The Presidium Gem Tester II relies primarily on thermal conductivity with basic electrical testing. It identifies simulants like CZ and moissanite successfully but provides limited lab-grown screening capability.

GIA's iD100 represents current state-of-the-art screening, incorporating infrared spectroscopy and advanced algorithms. Detection rates improve significantly over simple thermal testers, though exceptional CVD diamonds still present identification challenges.

Equipment Comparison:

- Basic thermal testers: <$200, minimal lab-grown detection

- Advanced screeners: $10,000+, moderate HPHT detection, limited CVD success

- Laboratory systems: $50,000+, multiple analysis methods required

Collaboration with certification laboratories reveals even advanced equipment requires multiple analysis methods for confident identification, particularly with high-quality CVD diamonds produced under optimal conditions.

"The reliance on a singular method such as thermal conductivity for distinguishing HPHT and CVD lab-grown diamonds from natural ones has proven inadequate in todays advanced gemological landscape. Our in-depth performance comparisons of various professional diamond testing equipment reveal that even top-tier devices integrating infrared spectroscopy and advanced algorithms face challenges with high-quality CVD stones. This underscores the necessity for a multi-technique approach, combining spectroscopy, electrical conductivity measurements, and more, to ensure accurate and reliable diamond identification."

Chemical Vapor Deposition vs High Pressure Manufacturing Impact

CVD manufacturing controls individual carbon atom deposition precisely, creating predictable properties and minimal impurities. HPHT mimics natural formation but introduces variables from metal catalysts and high-energy environments that affect final characteristics.

The CVD environment operates under controlled atmospheric conditions. Carbon-containing gases decompose in plasma fields, allowing organized crystalline arrangement. This atom-by-atom process enables unprecedented purity control.

CVD growth extends over weeks or months, allowing gradual development that minimizes stress and promotes uniformity. HPHT completes formation within days under extreme pressure—temperatures exceeding 2000°C and pressures over 50,000 atmospheres.

Silicon vacancy detection provides one CVD identification method through photoluminescence spectroscopy. CVD diamonds often show characteristic fluorescence at 738 nanometers under laser excitation. However, this requires laboratory equipment beyond standard gemological tools.

Our CVD manufacturing incorporates real-time growth monitoring, enabling immediate parameter adjustments throughout crystal development cycles for consistently superior quality.

Diamond Authentication Beyond Basic Tester Devices

Comprehensive authentication requires multiple techniques including spectroscopy, microscopic examination, and certification verification—basic testing proves insufficient for reliably distinguishing high-quality lab-grown from natural diamonds.

Infrared spectroscopy reveals molecular vibration patterns unique to different diamond types. It examines absorption bands correlating with nitrogen concentration and aggregation state. This requires specialized equipment and trained interpretation but provides definitive identification.

Photoluminescence spectroscopy excites diamonds with laser light, revealing formation-specific fluorescence. Certificate verification through GIA, IGI, and GCAL databases provides essential authentication beyond physical testing.

Authentication Methods:

- FTIR spectroscopy: Detects nitrogen aggregation differences

- UV transparency testing: Type IIa diamonds show superior transmission

- Magnetic testing: Identifies ferromagnetic inclusions in HPHT stones

- Laser inscription verification: Links to laboratory databases

Our comprehensive quality assurance involving multiple certification bodies confirms definitive authentication requires combining several analysis methods rather than relying on single testing approaches.

Why Professional Verification Matters More Than Ever

CVD diamonds' ability to pass standard testing while maintaining exceptional quality demonstrates the evolution of laboratory-grown technology. HPHT diamonds' variable results don't indicate inferior quality—they reflect different manufacturing approaches with distinct characteristics. Smart buyers recognize that proper authentication requires professional expertise beyond basic testing equipment.

Partner with Certified Diamond Experts Today

Labrilliante's comprehensive authentication process combines multiple analysis methods to guarantee accurate identification and certification. Our partnerships with leading gemological institutes ensure your diamond investment receives proper documentation and verification. Contact our diamond specialists to discuss authentication services and explore our curated selection of certified laboratory-grown diamonds backed by industry-leading quality assurance.

Frequently Asked Questions

Approximately 15-20% of HPHT diamonds fail electrical conductivity tests due to boron impurities from metal catalysts used during manufacturing. This contamination transforms diamonds from insulators into semiconductors, triggering false positives on electrical testing equipment.

CVD diamonds achieve Type IIa purity with nitrogen below 1 part per million, making them chemically identical to natural diamonds. HPHT diamonds contain boron contamination from iron, nickel, and cobalt catalysts that affects their electrical properties and testing behavior.

Basic thermal testers cost under $200 but provide minimal lab-grown detection, while advanced screeners cost $10,000+ with moderate HPHT detection capabilities. Laboratory-grade systems requiring multiple analysis methods cost $50,000+ for reliable identification of high-quality CVD diamonds.

CVD diamonds consistently achieve superior purity by producing Type IIa stones with nitrogen concentrations below 5 parts per million. This matches the rarest natural diamonds, while HPHT diamonds inevitably contain trace metal contamination from their manufacturing process regardless of starting material quality.

Type IIa diamonds contain virtually no nitrogen impurities and maintain electrical resistance values exceeding 10^16 ohm-centimeters, identical to the purest natural diamonds. Their thermal conductivity of 1000-2000 watts per meter-kelvin matches premium natural stones exactly, making standard detection impossible.

CVD uses methane and hydrogen gas mixtures in controlled plasma environments with zero nitrogen sources, eliminating common contaminants. The atom-by-atom deposition process operates at 700-900°C without metal catalysts, ensuring complete purity control throughout crystal formation.

Professional authentication requires combining multiple techniques including FTIR spectroscopy, photoluminescence testing, and certificate verification through GIA or IGI databases. Single-method testing proves insufficient for reliably distinguishing high-quality lab-grown from natural diamonds.

Jewelry professionals should upgrade to advanced screening equipment immediately if they regularly handle high-value diamonds or suspect lab-grown stones in their inventory. The investment pays off quickly considering that misidentification can result in significant financial losses and reputation damage.